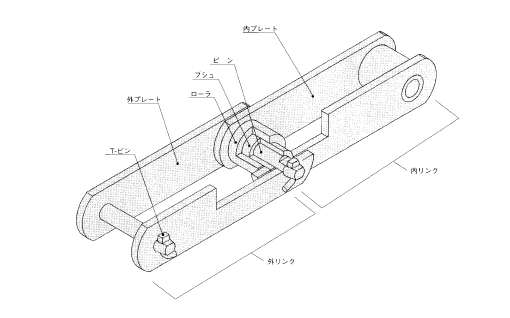

A DK conveyor chain features a structure, plus the names of the elements are stated in the drawing. These components have functions specified below.

Pins

Pins assistance all the load acting about the chain together with plates, and once the chain is engaged with all the sprockets, they slide along with bushings as bearings. These are subject to put on and particularly have to have large shear strength, bending strength and put on resistance. Hardened and tempered hard steel, carburized steel, or induction-hardened steel is utilized.

Rollers

Rollers safeguard the chain from shocks together with the sprockets, and once the chain is engaged together with the sprockets, the rollers bend the chain smoothly and act to lessen the resistance when the chain runs on a rail. They’re necessary to have

Bushings

Bushings are situated in between pins and rollers and act as bearings for both the pins and rollers to not transmit the load received through the rollers right for the pins when the chain is engaged with all the sprockets. They may be needed to possess large shock fatigue strength, collapse strength and wear resistance, and in general, carburized steel is utilised.

Plates

Plates are topic to repeated tension on the chain and in some cases to massive shocks. They are necessary to possess higher tensile strength, and especially large shock strength and fatigue power. Large tensile steel is applied for conventional chains and heat-treated alloy steel for heavy-duty chains.

T-pins

T-pins reduce the outer plates from disengaging from the pins. They may be made from soft steel considering the fact that pins are frequently pressed-in the outer plates and thus no massive force acts on the T-pins.