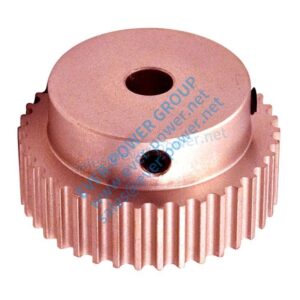

Polea de distribución con orificio piloto

Polea de distribución con orificio piloto

-

- Paso (R) = 77,62 mm

-

- Diámetro exterior (S) = 77,11 mm

-

- Ancho de la polea (W) = 14,3 mm

-

- Diámetro del cubo (H) = 52,0 mm

-

- Ancho del cubo (Y) = 25,0 mm

-

- Receso (Z) = 10,7 mm

- Se adapta a un cinturón de 3/8" de ancho.

Las poleas de distribución tienen ranuras equidistantes mecanizadas en el diámetro exterior para asegurar un engrane correcto con los dientes de la correa. Las ranuras de la polea están diseñadas para minimizar la fricción y lograr un engrane óptimo con los dientes de la correa. Todas las poleas fabricadas tienen tolerancias mínimas de engrane precisas y un diámetro primitivo siempre mayor que el diámetro exterior.

Introducción del producto

La polea de distribución con orificio piloto es una polea de alta calidad diseñada para un engrane preciso con las correas de distribución. Se utiliza ampliamente en diversas aplicaciones industriales, ofreciendo un rendimiento fiable y durabilidad.

Escenarios de uso común

- Sistemas de automatización industrial

- Maquinaria y equipo

- Robótica

- Prensas de imprenta

- Sistemas transportadores

Historial y clasificación del producto

La polea de distribución con orificio piloto tiene una larga trayectoria en aplicaciones industriales. Pertenece a la categoría de componentes de transmisión de potencia y es ampliamente reconocida por su precisión y fiabilidad.

Ventajas

- Ranuras mecanizadas con precisión para un engrane óptimo de la correa

- Material de alta calidad para una mayor durabilidad.

- Excelente rendimiento en aplicaciones exigentes

- Fácil instalación y mantenimiento

- Amplia gama de tamaños y configuraciones disponibles.

Material

La polea de distribución con orificio piloto generalmente está hecha de metales de alta resistencia o plásticos de ingeniería, lo que garantiza un rendimiento duradero incluso en condiciones de funcionamiento adversas.

Instalación, mantenimiento y reparación

La instalación de la polea de distribución con orificio piloto es un proceso sencillo. Es fundamental asegurar la correcta alineación y tensión de la correa de distribución para un rendimiento óptimo. El mantenimiento regular implica inspeccionar la polea para detectar cualquier signo de desgaste o daño y reemplazarla si es necesario. En caso de reparación, se recomienda consultar a un profesional o seguir las instrucciones del fabricante.

Reemplazo

Al reemplazar la polea de distribución del orificio piloto, es importante seleccionar el tamaño y las especificaciones correctos para garantizar la compatibilidad con la correa de distribución y el sistema en general. Se recomienda seguir las recomendaciones del fabricante para mantener un rendimiento óptimo.

Otros productos

Nuestra empresa se especializa en el suministro de una amplia gama de engranajes de plástico de alta calidad para diversas aplicaciones industriales. Nuestra gama de productos incluye cajas de engranajes agrícolas, ejes de transmisión, ruedas dentadas, acoplamientos hidráulicos, reductores de tornillo sin fin, engranajes y cremalleras, cadenas desmontables, poleas, reductores planetarios, poleas de distribución, bujes y más. Nos comprometemos a ofrecer productos excepcionales a precios competitivos y a brindar un excelente servicio al cliente. Invitamos a nuestros clientes a contactarnos para obtener soluciones personalizadas basadas en sus planos o muestras.

Preguntas y respuestas

1. ¿Cuáles son las características principales de la polea de distribución con orificio piloto?

La polea de distribución con orificio piloto tiene ranuras mecanizadas con precisión para un engrane óptimo de la correa, materiales de alta calidad para una mayor durabilidad, excelente rendimiento en aplicaciones exigentes, fácil instalación y mantenimiento, y una amplia gama de tamaños y configuraciones disponibles.

2. ¿En qué industrias se utiliza comúnmente la polea de distribución con orificio piloto?

La polea de distribución con orificio piloto encuentra un amplio uso en industrias como automatización industrial, maquinaria y equipo, robótica, prensas de impresión y sistemas de transporte.

3. ¿Qué materiales se utilizan para fabricar la polea de distribución con orificio piloto?

La polea de distribución con orificio piloto generalmente está hecha de metales de alta resistencia o plásticos de ingeniería para garantizar un rendimiento duradero en condiciones de funcionamiento difíciles.

4. ¿Cómo se debe instalar y mantener la polea de distribución del orificio piloto?

Durante la instalación, la alineación y la tensión correctas de la correa de distribución son cruciales para un rendimiento óptimo. El mantenimiento regular implica inspeccionar la polea para detectar desgaste o daños y reemplazarla si es necesario. Se recomienda consultar las instrucciones del fabricante para obtener instrucciones específicas.

5. ¿Se puede reemplazar la polea de distribución del orificio piloto? De ser así, ¿cómo?

Sí, la polea de distribución del orificio piloto se puede reemplazar. Es importante seleccionar el tamaño y las especificaciones correctos para garantizar la compatibilidad con la correa de distribución y el sistema en general. Se recomienda seguir las recomendaciones del fabricante para el reemplazo a fin de mantener un rendimiento óptimo.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios