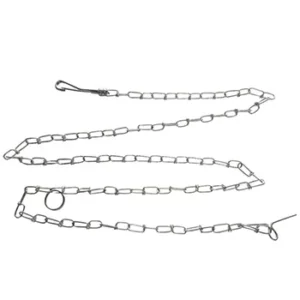

NACM2003 Standard Link Chain

The NACM2003 Standard Link Chain

The NACM2003 Standard Link Chain is specifically designed for marine applications and industrial environments. Its unique design and high-quality materials ensure durability and longevity. The chain is flexible and elastic, allowing for easy installation and use in various settings.

There are several finish options available for the NACM2003 Standard Link Chain, including galvanized, electro galvanized, black oxide, and natural. Additionally, the chain is available in different widths to suit different requirements.

To install a new chain, simply place it next to the old one, ensuring that the lengths match. If the new chain is too long, you can easily shorten it by cutting out some links.

Our company also offers a wide range of conveyor chain types. If you need more information on conveyor chain or other product types, please feel free to contact us by email or speak with our online staff. We are eager to assist you and look forward to working with you.

Safety Requirements for Link Chain

When using link chains, it is important to follow certain safety requirements to ensure safe operation. Here are some key guidelines:

1. Before use, thoroughly inspect the hook, chain, axle, and chain disk. If you notice any rust, cracks, damage, or inflexibility in the transmission part, do not use the chain.

2. During use, loosen the chain and hang the hoisting object. Slowly pull the traction chain and check the gear meshing and the working state of the self-locking device. Proceed with the operation only after confirming their proper functioning.

3. Make sure not to exceed the lifting capacity of the chain. In temperatures below -10°C, do not exceed half of the rated lifting capacity.

4. When pulling the chain, do so evenly and gently, following the direction of the sprocket wheel. Avoid dragging the chain obliquely to prevent issues like chain skipping, slot drop, and chain jamming.

5. If the weight of the lifted chain or the lifting object is unknown, one person should be able to pull the chain. If a single person cannot remove the chain, investigate the reason and strictly prohibit multiple people from pulling together to avoid accidents.

6. Regularly lubricate the gear part and inspect the pawl, spring, and ratchet. Faulty components can lead to falling objects and potential injuries, so it is crucial to prevent brake failure.

7. After use, disassemble and clean the inverted chain. Apply lubricating oil, properly store the chain by covering it with a plastic cover, and hang it up in a suitable location.

Piñones relacionados

Sprockets play a vital role in chain-driven motion systems, enhancing their efficiency and load-carrying capacity. Proper selection and installation of sprockets are essential to ensure optimal performance and prevent damage to the machine.

Unlike gears, sprockets are toothed wheels that mesh with chains as they rotate. They find application in a wide range of products, from bicycles to motor vehicles. When choosing a sprocket, consider factors such as system size, fit type, and durability requirements.

Sprocket life can vary significantly based on factors like riding style, conditions, chain pitch and size, and maintenance practices. Opting for sprockets with hardened teeth can triple the sprocket's lifespan, ensuring longer-lasting performance.

Nuestra ventaja

· We offer high-quality products at competitive prices.

· Our extensive product range is available in various materials and sizes.

· All our products are manufactured in an ISO9001:2008 certified factory.

· We take pride in providing excellent customer service and answering all your questions.

· We have the largest online selection of power transmission products.

· We specialize in high-quality made-to-order products.

Preguntas y respuestas

P: ¿Cuál es la fortaleza de su empresa?

A: Our company has a skilled engineering team experienced in product and machine designs. We can assist you in solving any issues you may encounter.

Q: How is the quality of your products?

A: We have our own professional factory and a dedicated workforce, ensuring that our products have a competitive edge over our competitors.

P: ¿Cuál es la cantidad mínima de pedido (MOQ)?

A: Our minimum order quantity is just one piece, allowing for flexibility in your purchasing needs.

P: ¿Pueden producir productos personalizados basados en dibujos o muestras?

A: Yes, we have extensive experience in manufacturing non-standard products and can produce them to your specifications.

P: ¿Qué otros negocios de productos ofrece su empresa?

A: In addition to our wide range of chain products, our company specializes in various industrial plastic gears, including agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more.

*Please note that all the content on this page is sourced from the internet and is intended solely as a reference for product selection

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios