Caja de engranajes para cortadora rotativa: reemplazo del código Comer LF227J

Caja de engranajes para cortadora rotativa LF-227J: reemplazo confiable de TEBSA para el código Comer LF-227J

Cuando se trata de mantener su cortadora de césped rotativa en óptimas condiciones, la caja de engranajes es el héroe anónimo que impulsa esas cuchillas giratorias a través del césped, la maleza y la vegetación resistente. En TEBSA, la sucursal argentina de HZPT, nos enorgullece ofrecer... Caja de engranajes para cortadora rotativa LF-227JUn reemplazo duradero y de alto rendimiento para el Comer Code LF-227J. Diseñada para maquinaria agrícola, tractores cortacésped y más, esta caja de cambios ofrece la fiabilidad y versatilidad necesarias para cualquier trabajo de corte.

¿Por qué elegir la caja de cambios para cortadora rotativa LF-227J?

El LF-227J no es una caja de cambios cualquiera: es una máquina potente diseñada para soportar los rigores de la siega rotativa. Con una Relación de transmisión 1:1,83 y un potencia máxima de entrada de 55 kW (75 CV)Tiene la potencia para impulsar las cuchillas de la cortadora de césped de manera eficiente. Con un peso de 37 kilos, es robusto carcasa GGG40 de hierro fundido Resiste las tensiones del uso diario, mientras que los rodamientos de gran tamaño y los engranajes endurecidos garantizan una larga vida útil. Ya sea que esté manteniendo una granja extensa o un césped bien cuidado, esta caja de cambios es la solución ideal.

¿Qué lo distingue? Su sistema de lubricación por baño de aceite Mantiene todo funcionando sin problemas, reduciendo la fricción y el desgaste con Aceite SAE 80W-90 (capacidad máxima: 0,8 litros) Agregue un sello de aceite para evitar fugas y tendrá una unidad que requiere poco mantenimiento y está diseñada para durar.

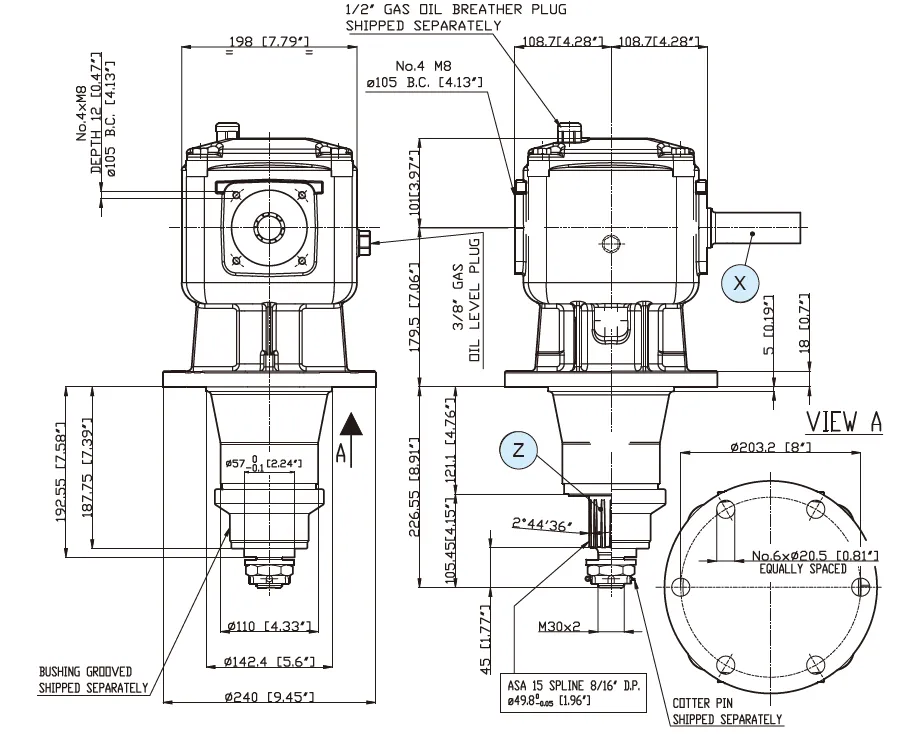

Especificaciones técnicas de un vistazo

Esto es lo que hace que el LF-227J funcione:

| Producto | Caja de engranajes para cortadora rotativa: reemplazo de la caja de engranajes Comer LF-227J |

| Solicitud | Cortadoras de césped |

| Potencia máxima de entrada | 55 kW / 75 CV |

| Relación de transmisión | 1:1.83 (Aumentante) / 1.83:1 (Reductor) |

| Par de salida | 51,7 daNm |

| Material de la carcasa | Hierro fundido GGG40 |

| Peso | 37 kilos |

| Capacidad de aceite | 0,8 litros (Se suministra sin aceite) |

| Tipo de aceite | SAE 80W-90 |

| Intervalo de cambio de aceite | Primer cambio después de 50-70 horas, luego cada 500-700 horas o anualmente |

| Eje de entrada | 1 3/8" (6 estrías) |

| Eje de salida | ASA Z15 DP 8/16 |

Nota: Las cajas de cambios se envían sin aceite, así que asegúrese de llenarlas antes de usarlas.

Características clave que distinguen al LF-227J

- Duro como una roca: La carcasa de hierro fundido absorbe los golpes y sacudidas del trabajo de campo.

- Alta capacidad de carga: Los cojinetes y engranajes de gran tamaño permiten realizar cortes pesados con facilidad.

- Operador suave: El sistema de baño de aceite mantiene las partes internas resbaladizas, lo que reduce el desgaste.

- Conectar y usar: Fácil de instalar: no se necesitan ajustes personalizados para la mayoría de las cortadoras de césped.

- Poco alboroto: Un mantenimiento mínimo significa más tiempo cortando el césped y menos tiempo haciendo ajustes.

Desde pequeños tractores de césped hasta grandes instalaciones agrícolas, el LF-227J se adapta a sus necesidades, lo que lo convierte en una opción versátil para cualquier tarea con cortadora de césped rotativa.

Dentro del LF-227J: Componentes principales

Esta caja de cambios es una sinfonía de piezas que trabajan juntas:

- Eje de entrada: Se conecta a la toma de fuerza (TDF) de su tractor (1 3/8", 6 estrías) para suministrar potencia.

- Engranajes: Templados para cargas pesadas, transfieren torque en una relación de 1:1.83.

- Aspectos: Apoye las piezas giratorias, manteniendo baja la fricción.

- Sello de aceite: Retiene el lubricante y mantiene alejada la arenilla.

- Alojamiento: El hierro fundido GGG40 protege las entrañas del mundo exterior.

- Eje de salida: Envía 51,7 daNm de par a sus cuchillas (ASA Z15 DP 8/16).

- Sistema de lubricación: El baño de aceite mantiene todo funcionando correctamente.

Los controles regulares, como revisar el nivel de aceite o cambiar los sellos, mantienen estas piezas sincronizadas y su cortadora de césped cortando limpio.

Cómo mantener su caja de cambios LF-227J

¿Quieres que tu caja de cambios dure más? Aquí te explicamos cómo mantenerla en perfecto estado:

- Compruebe los niveles de aceite: Estaciónelo nivelado, saque la varilla de nivel y asegúrese de que el aceite esté entre las marcas. Si el nivel está bajo, rellene con SAE 80W-90.

- Cambie el aceite según lo programado: El primer cambio se debe hacer después de 50-70 horas, luego cada 500-700 horas o una vez al año.

- Esté atento a las filtraciones: ¿Gotea la podadora? Revisa el retén de aceite pronto.

- Escuche: ¿Ruidos extraños? Podrían ser rodamientos o engranajes; no esperes a inspeccionarlos.

Un poco de cariño y atención puede ayudar mucho a evitar grandes reparaciones.

¿Necesitas cambiar tu caja de cambios? Esto es lo que debes saber

¿Sustituir un viejo Comer LF-227J por la versión de TEBSA? La seguridad es lo primero:

- Use guantes y gafas protectoras: el metal es implacable.

- Desconecte el eje de la toma de fuerza para evitar sorpresas.

- Asegure la cortadora de césped con soportes de gato, sin permitir que se tambalee.

- Utilice una llave dinamométrica: los pernos necesitan que esa potencia de 55 kW se gestione correctamente.

- Llénelo con 0,8 litros de SAE 80W-90 antes de encenderlo.

Sigue estos pasos y tu nuevo LF-227J encajará como si hubiera nacido allí.

Ejes de toma de fuerza: la pareja perfecta

Ninguna caja de cambios funciona sola; necesita un eje de toma de fuerza sólido. El LF-227J se combina con un Eje de toma de fuerza de 1 3/8" y 6 estríasConecta la potencia de tu tractor a la potencia de la cortadora. Mantenlo engrasado, limpio y sin residuos, y girará esos 55 kW como un sueño. TEBSA ofrece opciones de toma de fuerza (540, 1000 o de doble velocidad) para adaptarse a tu configuración.

Más que simples cortadoras de césped: la línea de cajas de cambios de TEBSA

Además del LF-227J, TEBSA ofrece una gama completa de cajas de engranajes agrícolas: desbrozadora rotativa, abonadora, excavadora de hoyos, cultivador y más. Sean cuales sean las necesidades de su explotación, tenemos el equipo necesario para que siga funcionando.

¿Por qué TEBSA? Su socio de confianza desde 1997

TEBSA, la filial argentina de HZPT, aporta más de 25 años de experiencia. Desde 1997, fabricamos reductores que ofrecen... 100% calidad garantizada. Nuestro precios competitivos—hasta 50% menos que las grandes marcas— significa que obtienes equipo de primera calidad sin gastar una fortuna. Desde prototipos rápidos hasta producción en masa, nuestros talentoso equipo de ingeniería Responde en 24 horas, lo que facilita la colaboración y facilita la confianza. TEBSA para soluciones confiables, asequibles y adaptadas a los campos de Argentina.

Consigue tu LF-227J hoy

¿Listo para potenciar su cortacésped rotativo? Contacte con TEBSA para el LF-227J o cualquier caja de engranajes agrícola que necesite. Estamos aquí para que su granja siga funcionando a la perfección. ¡Contáctenos ahora!

Preguntas frecuentes (FAQ)

1. ¿Qué hace que el LF-227J sea un buen reemplazo para el Comer LF-227J?

El LF-227J de TEBSA cumple con las especificaciones de Comer, con una relación de aspecto de 1:1,83, 55 kW de potencia y carcasa de hierro fundido GGG40. Es robusto, versátil y fácil de instalar, perfecto para intercambiarlo sin problemas.

2. ¿Con qué frecuencia debo revisar el aceite de mi caja de cambios LF-227J?

Revíselo antes de cada trabajo importante: tire de la varilla de nivel en una superficie nivelada. Cambie el aceite después de 50-70 horas inicialmente, luego cada 500-700 horas o anualmente con SAE 80W-90 para mantener un funcionamiento óptimo.

3. ¿El LF-227J puede realizar cortes de césped pesados?

Por supuesto: sus grandes rodamientos, engranajes endurecidos y un par motor de 51,7 daNm desgarran la hierba espesa y la maleza. Está diseñado para 55 kW (75 CV), así que las cargas pesadas no suponen ningún problema.

4. ¿Qué eje de toma de fuerza funciona con el LF-227J?

Necesitará un eje de toma de fuerza de 1 3/8" y 6 estrías. TEBSA tiene opciones (540, 1000 o de doble velocidad) que, si se mantiene engrasado y limpio, se combinará perfectamente con el eje de entrada del LF-227J.

5. ¿Por qué comprar en TEBSA en lugar de una gran marca?

Desde 1997, TEBSA ofrece calidad a la mitad del precio de las grandes marcas: ¡hasta un ahorro de 50%! Nuestro equipo es rápido (responde en 24 horas) y confiable, con una garantía de calidad de 100% que respalda cada caja de cambios.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios