Caja de engranajes de mezclador de alimentación horizontal: reemplazo de la caja de engranajes Comer C3A 1:1

Caja de engranajes de mezclador de alimentación horizontal: reemplazo de la caja de engranajes Comer C3A 1:1

La caja de engranajes para mezcladoras de alimento horizontal, diseñada por TEBSA como reemplazo directo de la Comer C3A, satisface las rigurosas exigencias de la mezcla de alimentos agrícolas en Argentina y el resto del mundo. Desde 1997, TEBSA ha sido una marca de confianza en la fabricación, ofreciendo la garantía de calidad 100% y una ventaja de costo 50% sobre las marcas originales. Esta caja de engranajes cumple con las dimensiones y especificaciones de la Comer C3A, garantizando una integración perfecta en las mezcladoras de alimento existentes para obtener resultados consistentes y de alto rendimiento.

Fabricada con acero endurecido y hierro fundido, esta caja de engranajes está diseñada para ofrecer durabilidad, soportando las cargas y tensiones constantes del procesamiento de alimentos. Sus engranajes y cojinetes de alta calidad, fabricados mediante forjado avanzado y tratamiento térmico (como la carburación), ofrecen una resistencia duradera. La caja de engranajes permite una transmisión de potencia eficiente con una relación de transmisión de 1:1, optimizando el proceso de mezcla para aumentar la productividad. Características como una carcasa reforzada y un sistema de lubricación sellado minimizan el mantenimiento y mejoran la confiabilidad, manteniendo sus sistemas de mezcla de alimentos funcionando sin problemas en los exigentes entornos agrícolas de Argentina, como las plantaciones de soja y maíz en la Pampa.

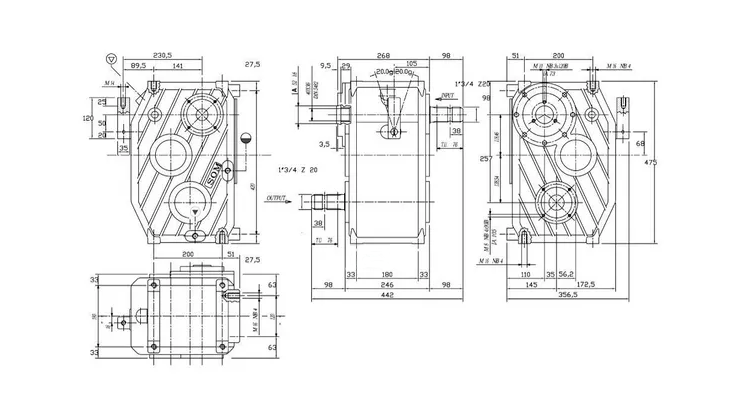

Dimensiones de la caja de engranajes del mezclador de alimentación horizontal C3A

Especificaciones del producto

| Descripción del Producto |

Caja de engranajes de mezclador de alimentación horizontal: reemplazo de la caja de engranajes Comer C3A 1:1

|

|---|---|

| Detalles del producto |

|

| Rango de aplicación |

Vagón mezclador

|

| Modelo |

C3A

|

| Factor de proporción |

1:1

|

| Velocidad máxima de rotación de entrada |

540 rpm

|

| Consiste en |

|

| Potencia máxima de entrada |

92 kW

|

| Tipo de conexión 1 |

Estriado

|

| Diámetro exterior de la conexión 1 |

1-3/8 pulgadas

|

| Conexión 1 número de splines |

6

|

| Tipo de conexión 2 |

Estriado

|

| Conexión 2 diámetro exterior |

1-3/4 pulgadas

|

| Conexión 2 número de splines |

20

|

| Contiene aceite |

No

|

|

90

|

¿Por qué elegir la caja de engranajes del mezclador de alimentos C3A para granjas argentinas?

La caja de engranajes del mezclador de alimentación horizontal de TEBSA Es una innovación para los productores de Argentina, especialmente en regiones como Buenos Aires, Córdoba y Santa Fe, donde la ganadería y la producción lechera prosperan. Diseñada para reemplazar la Comer C3A, esta caja de engranajes garantiza el funcionamiento fluido de su carro mezclador de alimento, entregando mezclas uniformes, esenciales para la salud y la productividad animal. Su robusta carcasa de hierro fundido y engranajes de acero endurecido, procesados mediante técnicas avanzadas como la carburación y la molienda, soportan el trabajo diario de mezclar ensilado, granos y suplementos.

La relación de transmisión 1:1 de esta caja de engranajes y su velocidad de entrada de 540 RPM optimizan la transferencia de potencia, lo que la hace ideal para mezcladores de alimento horizontales utilizados en las explotaciones ganaderas y lecheras de Argentina. Las conexiones estriadas (1-3/8" con 6 estrías y 1-3/4" con 20 estrías) garantizan una conexión segura a los cardanes, una configuración común en la maquinaria agrícola argentina. Con una potencia máxima de entrada de 92 kW, gestiona las cargas pesadas de la mezcla de grandes lotes de alimento, reduciendo el tiempo de inactividad y aumentando la eficiencia.

El reemplazo C3A de TEBSA ofrece una ventaja en el costo del 50% sobre los modelos Comer originales, lo que lo convierte en una opción inteligente para agricultores que buscan mantener un alto rendimiento sin gastar una fortuna. El sistema de lubricación sellado reduce el mantenimiento, requiriendo solo un llenado inicial de aceite (viscosidad SAE 90) y cambios después de 50-70 horas, y luego cada 500-700 horas o anualmente. Este diseño de bajo mantenimiento se adapta a las apretadas agendas de los agricultores argentinos, especialmente durante temporadas altas como las cosechas de soja o maíz.

Para aplicaciones como la mezcla de alimento para ganado en la Pampa, esta caja de engranajes garantiza un rendimiento constante, consolidando la reputación de Argentina como líder mundial en la producción de carne de res. Su compatibilidad con las configuraciones Comer C3A existentes evita costosas modificaciones, solo confiabilidad inmediata. Ya sea que mezcle alimento para vacas lecheras en Santa Fe o ganado vacuno en La Pampa, la caja de engranajes de TEBSA cumple con sus expectativas.

Características técnicas y consejos de mantenimiento

La caja de engranajes del mezclador de alimentación horizontal C3A destaca por su precisión técnica y su diseño intuitivo. Sus características principales incluyen:

Materiales duraderos: Carcasa de hierro fundido y engranajes de acero endurecido, tratados con carburación para resistencia al desgaste.

Transferencia de potencia eficiente: relación de engranajes 1:1 y velocidad de entrada de 540 RPM para una mezcla óptima.

Cojinetes de alta resistencia: Los cojinetes de alta calidad admiten un funcionamiento continuo con un par elevado (hasta 92 kW).

Lubricación sellada: Reduce el mantenimiento con un sistema sellado, que requiere aceite SAE 90 (no incluido).

Conexiones estriadas: 1-3/8 pulgadas (6 estrías) y 1-3/4 pulgadas (20 estrías) para una integración segura de la TDF.

Para mantener su caja de cambios funcionando sin problemas, siga estos consejos de mantenimiento:

| Tarea | Frecuencia | Detalles |

|---|---|---|

| Llenado inicial de aceite | Antes del primer uso | Utilice aceite SAE 90; llene hasta el nivel recomendado. |

| Primer cambio de aceite | Después de 50-70 horas | Drene y reemplace con aceite SAE 90 nuevo. |

| Cambio de aceite regular | Cada 500-700 horas o anualmente | Verifique si hay contaminantes; reemplace el aceite según sea necesario. |

| Inspeccionar los sellos | Mensual | Busque fugas o desgaste; reemplace los sellos si es necesario. |

| Comprobar la alineación | Trimestral | Asegúrese de que la caja de cambios y el eje de la toma de fuerza estén correctamente alineados. |

Estas medidas, respaldadas por el soporte de ingeniería de TEBSA las 24 horas, garantizan confiabilidad a largo plazo, minimizando las interrupciones durante temporadas agrícolas críticas en Argentina.

Aplicaciones y beneficios de la mezcla de piensos en Argentina

La caja de engranajes para mezcladores de alimento C3A está diseñada para mezcladores de alimento horizontales, un elemento básico en la industria ganadera argentina. Impulsa vagones mezcladores que combinan ensilado, heno, granos y suplementos proteicos en raciones de alimento balanceadas. Esto es vital para las explotaciones lecheras de Córdoba, donde la calidad constante del alimento impulsa la producción de leche, y para las explotaciones ganaderas de Buenos Aires, donde la uniformidad del alimento favorece la ganancia de peso.

Los beneficios clave incluyen:

Productividad mejorada: La relación de engranajes de 1:1 garantiza una mezcla eficiente, reduciendo el tiempo de procesamiento.

Ahorro de costos: la ventaja de costo del 50% de TEBSA lo convierte en un reemplazo asequible para las cajas de engranajes Comer C3A.

Durabilidad: El acero endurecido y el hierro fundido resisten la naturaleza abrasiva de los materiales de alimentación.

Bajo mantenimiento: la lubricación sellada y los componentes reemplazables simplifican el mantenimiento.

Relevancia local: Diseñado para los mezcladores impulsados por PTO de Argentina, es ideal para granjas en Santa Fe, La Pampa y más allá.

En Argentina, donde la agricultura es el motor de la economía, esta caja de engranajes facilita la producción de alimento de alta calidad para ganado, productos lácteos y aves de corral. Su capacidad para procesar materiales resistentes como ensilado de maíz o harina de soja la convierte en una opción confiable para operaciones a gran escala. Quienes busquen en línea "caja de engranajes para mezclador de alimento horizontal en Argentina" o "caja de engranajes de repuesto para Comer C3A" encontrarán la solución de TEBSA accesible y a un precio competitivo.

Acerca de TEBSA y nuestra gama de cajas de engranajes agrícolas

Desde 1997, TEBSA, la filial argentina de HZPT, es un fabricante de confianza de componentes agrícolas e industriales. Con sede en Argentina, combinamos la experiencia local con los estándares globales, con certificación ISO9001-2015 y un compromiso con la calidad 100%. Nuestro equipo de ingeniería responde en 24 horas, garantizando a los agricultores de Buenos Aires, Córdoba o Santa Fe un soporte rápido. Con la ventaja de costo 50%, ofrecemos valor sin comprometer el rendimiento.

Más allá de la caja de engranajes del mezclador de alimentación horizontal C3A, TEBSA ofrece una amplia gama de cajas de cambios agrícolas, incluido:

Cajas de engranajes para cortadoras rotativas: para cortar césped y limpiar terrenos (por ejemplo, modelo RC-61).

Cajas de engranajes para esparcidores de fertilizantes: para una aplicación precisa de nutrientes.

Cajas de engranajes para cultivadores rotativos: para la preparación del suelo en campos de soja y maíz.

Cajas de engranajes para segadoras de mayales: para un control intensivo de la vegetación.

Ejes TDF: Para transferencia de potencia en diversos implementos agrícolas.

Cada producto se fabrica con materiales como acero aleado, acero inoxidable o hierro fundido, mediante procesos como forjado, rectificado y tratamiento térmico (p. ej., carbonitruración). Ya sea que esté modernizando un mezclador de pienso en La Pampa o una cortadora rotativa en la Pampa, las soluciones de TEBSA están diseñadas para durar. Contáctenos en cajas-de-engranajes-agrícolas.com para explorar nuestra gama completa o solicitar un presupuesto para su próximo proyecto.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios