Caja de engranajes de mezclador de alimentación horizontal: reemplazo de la caja de engranajes Comer D732A 1:1/1.93:1

Caja de engranajes de mezclador de alimentación horizontal: reemplazo de la caja de engranajes Comer D732A 1:1/1.93:1

La caja de engranajes para mezcladoras de alimento horizontal, diseñada como reemplazo directo del modelo Comer D732A, es un componente vital para las operaciones de mezcla de alimentos agrícolas en Argentina. Diseñada por TEBSA, fabricante de confianza desde 1997, esta caja de engranajes cumple con las especificaciones del modelo original para una compatibilidad perfecta y un rendimiento excepcional. Diseñada para la exigente tarea de mezclar alimento para el ganado, garantiza eficiencia y confiabilidad en entornos agrícolas difíciles como la llanura pampeana. Con la garantía de calidad 100% y la ventaja de costo 50% sobre las marcas originales, TEBSA Ofrece una solución duradera y de alto valor.

Fabricada en hierro fundido GG25, la caja de engranajes resiste el desgaste y el uso continuo en el procesamiento de alimentos. Sus engranajes y cojinetes mecanizados con precisión soportan cargas pesadas, mientras que la carcasa reforzada minimiza la necesidad de mantenimiento. Las relaciones de transmisión personalizadas (1:1 o 1,93:1) optimizan la mezcla para tareas específicas, aumentando la productividad de los agricultores argentinos que trabajan con soja, maíz o alimento para ganado. Esta caja de engranajes de repuesto garantiza el buen funcionamiento de su operación, reduciendo el tiempo de inactividad y mejorando la producción.

¿Por qué elegir la caja de cambios de repuesto TEBSA D732A?

La caja de engranajes del mezclador horizontal de pienso TEBSA destaca por su diseño robusto y sus prácticas ventajas, adaptadas a las necesidades del sector agrícola argentino. Por eso es una opción inteligente:

Compatibilidad perfecta: Diseñado para reemplazar el Comer D732A, se adapta perfectamente a los mezcladores de alimento existentes, garantizando una instalación rápida y sin modificaciones. Esto lo hace ideal para ganaderos de Buenos Aires o Córdoba que buscan una actualización sin complicaciones.

Alta durabilidad: Fabricado en hierro fundido y con engranajes tratados térmicamente (mediante carburación), soporta los rigores de la mezcla diaria de alimentos, desde pequeñas granjas lecheras hasta grandes operaciones de ganado.

Rendimiento optimizado: Con relaciones de engranaje de 1:1 o 1,93:1, proporciona una transferencia de potencia precisa, mejorando la consistencia de la mezcla para el alimento del ganado, ya sea para aves de corral, cerdos o ganado vacuno.

Bajo mantenimiento: La carcasa reforzada y los sellos de rodillos cónicos reducen el desgaste, mientras que los cambios de aceite simples (cada 500 a 700 horas) lo mantienen funcionando sin problemas.

Ahorro de costos: La ventaja de costo del 50% de TEBSA sobre las cajas de engranajes originales significa que usted obtiene calidad superior sin gastar una fortuna, un factor clave para las agroindustrias argentinas.

Soporte local: Nuestro equipo de ingeniería, con sede en Argentina, responde en 24 horas y ofrece asesoramiento experto para instalación, mantenimiento o personalización.

Esta caja de cambios es un socio confiable para los remolques mezcladores de alimentos, asegurando un rendimiento constante en el diverso paisaje agrícola de Argentina, desde los campos de soja hasta las pasturas de pastoreo.

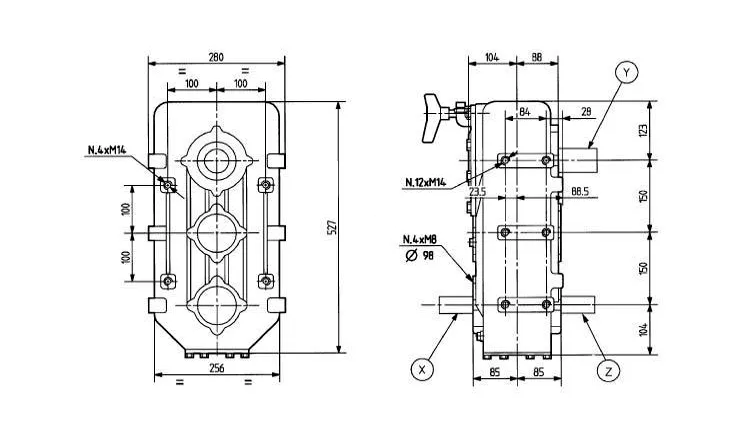

Especificaciones técnicas y características

La caja de engranajes de repuesto TEBSA D732A está diseñada para ofrecer precisión y potencia, con especificaciones diseñadas para satisfacer las demandas de los mezcladores de alimentación horizontales. A continuación, se presentan los detalles clave:

| Descripción del Producto |

Caja de engranajes de mezclador de alimentación horizontal: reemplazo de la caja de engranajes Comer D732A 1:1/1.93:1

|

|---|---|

| Detalles del producto |

|

| Rango de aplicación |

Vagón mezclador

|

| Factor de proporción |

1:1.93

|

| Consiste en |

|

| Potencia máxima de entrada |

59 kW

|

| Potencia máxima de salida |

80 caballos

|

| Diámetro exterior de la conexión 1 |

1-3/8 pulgadas

|

| Conexión 1 número de splines |

6

|

| Conexión 2 diámetro exterior |

60 milímetros

|

| Contiene aceite |

No

|

| Capacidad máxima de aceite |

5,6 litros

|

| Intervalo máximo de cambio de aceite |

500 horas

|

| Grado de viscosidad SAE del aceite |

80W-90

|

| Material de la carcasa |

Hierro fundido GG25

|

| Peso |

63 kilos

|

Características técnicas adicionales

- Mecanizado de precisión:Los engranajes están tallados y rectificados para lograr una transferencia de potencia suave, lo que reduce el ruido y el desgaste.

- Tratamiento térmico:Los engranajes carburados mejoran la dureza, ideal para las tareas de mezcla de alimentos de alta intensidad de Argentina.

- Sistema de sellado:Los sellos de rodillos cónicos evitan fugas, protegiendo los componentes internos del polvo y la humedad en regiones húmedas como Entre Ríos.

Aplicaciones y Mantenimiento para Granjas Argentinas

La caja de engranajes de repuesto TEBSA D732A está diseñada para carros mezcladores de alimento horizontales, un elemento básico en la industria ganadera argentina. Ya sea que mezcle alimento para ganado en Santa Fe o para aves de corral en Mendoza, esta caja de engranajes garantiza una mezcla uniforme, crucial para la salud animal y la eficiencia de la granja. Sus 80 HP de potencia y 59 kW de entrada son ideales para operaciones de mediana a gran escala, mientras que la relación de transmisión de 1:1.93 optimiza el par para mezclas de alimento espesas.

Aplicaciones clave

| Solicitud | Descripción | Palabras clave relevantes |

|---|---|---|

| Mezcla de alimento para ganado | Mezcla maíz, soja y ensilaje para ganado lechero y de carne en la Pampa. | Caja de engranajes para mezclador de alimento para ganado, caja de engranajes agrícola Argentina |

| Procesamiento de alimentos para aves de corral | Manipula granos finos para granjas avícolas en Buenos Aires. | Caja de engranajes para mezclador de alimento para aves de corral, caja de engranajes de hierro fundido para alimento |

| Producción de alimento para cerdos | Mezcla alimentos de alto valor proteico para granjas porcinas en Córdoba. | Caja de engranajes para alimentación de cerdos, caja de engranajes para mezclador de alimento duradera |

Consejos de mantenimiento

Para mantener la caja de cambios en óptimas condiciones:

Configuración inicial: Llene con 5,6 litros de aceite 80W-90 antes de usar, ya que se envía sin aceite.

Cambios de aceite: Reemplace el aceite después de 50 a 70 horas, luego cada 500 a 700 horas o anualmente.

Inspecciones: Revisar mensualmente si hay fugas o desgaste, especialmente en regiones polvorientas como La Pampa.

Alineación: Asegúrese de que la caja de engranajes y el mezclador estén alineados para evitar tensiones en la conexión de 1-3/8 pulgadas y 6 estrías.

Lubricación: Utilice únicamente aceite 80W-90 aprobado por el fabricante para mantener la integridad del engranaje.

El mantenimiento regular previene tiempos de inactividad, asegurando la productividad de su mezclador de alimento durante las intensas temporadas de cosecha en Argentina. El equipo de TEBSA está disponible las 24 horas, los 7 días de la semana para responder preguntas o proporcionar repuestos, manteniendo su operación en marcha.

Acerca de TEBSA y nuestras soluciones agrícolas

Desde 1997, TEBSA ha sido un fabricante líder de cajas de engranajes agrícolas en Argentina, ofreciendo soluciones confiables y rentables a agricultores y operadores industriales. Con sede en Argentina, nos enorgullecemos de nuestra garantía de calidad 100%, nuestra ventaja de precio 50% frente a las marcas originales y un equipo de ingeniería cualificado que responde en 24 horas. Con certificación ISO 9001-2015, utilizamos procesos avanzados como forjado, carburación y rectificado de precisión para producir productos duraderos a la medida de las necesidades agrícolas de Argentina.

Además de la caja de engranajes para mezcladoras de pienso horizontales, TEBSA ofrece una amplia gama de cajas de engranajes agrícolas, que incluyen:

Cajas de engranajes para cortadoras rotativas: para corte y gestión de residuos de cultivos.

Cajas de engranajes para esparcidores de fertilizantes: para una distribución precisa de nutrientes.

Cajas de engranajes para cultivadores rotativos: para la preparación del suelo en campos de soja y trigo.

Cajas de engranajes para segadoras de mayales: para un control intensivo de la vegetación.

Ejes TDF: Para una transferencia de potencia eficiente en maquinaria agrícola.

Ya sea que esté en Buenos Aires, Mendoza o Santa Fe, TEBSA es su socio de confianza para cajas de engranajes agrícolas. Contáctenos hoy para obtener más información sobre la caja de cambios de reemplazo D732A o explorar nuestra línea completa de productos.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios