Rueda dentada del transportador

Las ruedas dentadas para transportadores son la base de los sistemas eficientes de manejo de materiales, impulsando cadenas para un transporte fluido de mercancías en diferentes industrias. TEBSA, con sede en Argentina desde 1997, fabrica ruedas dentadas para transportadores de alta calidad que impulsan desde silos de granos en la Pampa hasta plantas procesadoras de alimentos en Buenos Aires. Nuestras ruedas dentadas, fabricadas con precisión y durabilidad, garantizan un funcionamiento impecable en entornos exigentes. Con la garantía de calidad 100% y la ventaja de precio 50% frente a las marcas originales, TEBSA ofrece soluciones confiables con el respaldo de un equipo que responde en 24 horas. Diseñadas para acoplarse perfectamente a las cadenas transportadoras, nuestras ruedas dentadas transfieren el movimiento con mínima fricción, lo que reduce el desgaste y aumenta la productividad. Fabricadas con materiales como acero de alta calidad, acero inoxidable y aluminio, resisten la corrosión, cargas pesadas y condiciones adversas. Ya sea en la agricultura, la manufactura o la minería, las ruedas dentadas para transportadores de TEBSA mantienen sus operaciones en marcha. Desde diseños estándar hasta pedidos personalizados, adaptamos soluciones a sus necesidades, garantizando la compatibilidad con cadenas de rodillos ANSI y varios tipos de orificios.

Piñón de transportador en venta

Aplicaciones y desempeño en las industrias argentinas

Las ruedas dentadas para transportadores de TEBSA impulsan una amplia gama de industrias en Argentina, desde la agricultura hasta la industria pesada. En la Pampa, impulsan transportadores de granos, garantizando el transporte eficiente de trigo y maíz a los silos. En Buenos Aires, las plantas procesadoras de alimentos confían en ruedas dentadas de acero inoxidable para un rendimiento higiénico y resistente a la corrosión. Las operaciones mineras en Catamarca utilizan ruedas dentadas Tipo C para manipular cargas pesadas de mineral, mientras que las plantas de reciclaje en Rosario se benefician de ruedas dentadas partidas para un mantenimiento rápido. Nuestras ruedas dentadas están diseñadas para la precisión, con perfiles de dientes y pasos precisos que se adaptan a las cadenas transportadoras, lo que reduce el desgaste y garantiza un funcionamiento suave. Materiales como el acero endurecido y el acero inoxidable proporcionan resistencia al desgaste, crucial para entornos abrasivos como la producción de cemento. Para entornos sensibles al ruido, como las líneas de envasado en interiores, ofrecemos perfiles de dientes con reducción de ruido. Los compradores en línea que buscan "proveedor de ruedas dentadas para transportadores en Argentina" encuentran los productos de TEBSA confiables y rentables, gracias a nuestra ventaja de costo 50%.

| Industria | Solicitud | Tipo de rueda dentada | Beneficio | Palabra clave SEO |

|---|---|---|---|---|

| Agricultura | Transportadores de granos para trigo y maíz | QD | Instalación rápida, durable para cosechas pampeanas | Piñón de transportador agrícola Argentina |

| Procesamiento de alimentos | Líneas de envasado en plantas de Buenos Aires | Acero inoxidable | Higiénico, resistente a la corrosión para la seguridad alimentaria. | Piñón de acero inoxidable para procesamiento de alimentos |

| Minería | Transporte de mineral en minas de Catamarca | Alta capacidad de par para cargas pesadas | Piñón transportador de minería Argentina | |

| Reciclaje | Clasificación de materiales en las instalaciones de Rosario | Piñón partido | Mantenimiento rápido, tiempo de inactividad reducido | Piñón partido para reciclaje Argentina |

| Fabricación de cemento | Transportadores de banda en plantas de Córdoba | Acero endurecido | Resistente al desgaste para entornos abrasivos. | Piñón transportador de acero endurecido |

Consejos de selección y mantenimiento para ruedas dentadas de transportadores

La elección de la rueda dentada transportadora adecuada garantiza un rendimiento óptimo y una larga vida útil. Paso:Adapte el paso de la rueda dentada a la distancia del pasador de la cadena para lograr un engrane adecuado. – Número de dientesMenos dientes aumentan la velocidad, mientras que más dientes aumentan el par. Los dientes impares prolongan la vida útil de la cadena al distribuir el desgaste uniformemente. Material:El acero es adecuado para tareas pesadas; el acero inoxidable es ideal para entornos corrosivos como el procesamiento de alimentos. – Tipo de orificio:Los orificios terminados con chaveteros ofrecen un fácil montaje; los bujes de bloqueo cónico o QD proporcionan una rápida instalación y extracción. – Perfil del dienteLos dientes endurecidos por inducción mejoran la resistencia al desgaste, mientras que los perfiles de reducción de ruido facilitan un funcionamiento silencioso. Para el mantenimiento, inspeccione regularmente los piñones para detectar desgaste o acumulación de residuos. Lubrique los dientes y las cadenas con grasa de alta calidad para reducir la fricción. Compruebe la alineación con una regla o una herramienta láser para evitar una distribución desigual de la carga. Reemplace los piñones y las cadenas juntos para evitar un desgaste prematuro, ya que los piñones desgastados pueden estirar las cadenas nuevas. El equipo de TEBSA está disponible 24/7 para ayudarle con la selección o la resolución de problemas, garantizando así el correcto funcionamiento de sus transportadores.

Presentación de ruedas dentadas para transportadores TEBSA

A continuación se muestran algunas de las mejores ruedas dentadas para transportadores de TEBSA, diseñadas para diversas aplicaciones: – FBK50BPiñón de 50 dientes con orificio terminado tipo B, fabricado en acero C45. Ideal para transportadores de servicio medio en plantas de cemento, ofrece fácil montaje y alta resistencia al desgaste. QD60BPiñón de desconexión rápida con 60 dientes y buje de desconexión rápida. Ideal para transportadores de granos agrícolas, garantiza una instalación rápida y una distribución uniforme de la carga. SS-A35Piñón tipo A de acero inoxidable con 35 dientes, ideal para líneas de procesamiento de alimentos. Su diseño resistente a la corrosión cumple con las normas de higiene.

Acerca de TEBSA y nuestras soluciones industriales

Desde 1997, TEBSA ha sido el fabricante de confianza de componentes de transmisión de potencia en Argentina, prestando servicio a granjas, fábricas y minas con productos con certificación ISO 9001-2015. Nuestros piñones para transportadores, cajas de engranajes y ejes de toma de fuerza se fabrican mediante técnicas avanzadas como forjado, carburación y temple por inducción, lo que garantiza durabilidad y precisión. Con la ventaja de costo de la norma 50% y un equipo de respuesta las 24 horas, somos su socio ideal para soluciones confiables y rentables. Nuestra gama de productos incluye: Cajas de cambios:Al igual que las cajas de engranajes de la cortadora rotativa RC-61 y la esparcidora de fertilizantes L-25A para tareas agrícolas. – Ejes de toma de fuerza:Para una transferencia de potencia eficiente en tractores e implementos. – Cadenas de rodillos:Cadenas duraderas para transportadores y maquinaria. – Otras ruedas dentadasPiñones de diámetro estándar, con bloqueo cónico y tensores para diversas aplicaciones. Contacte hoy mismo con TEBSA para encontrar el piñón transportador perfecto para sus necesidades, desde Mendoza hasta la Pampa.

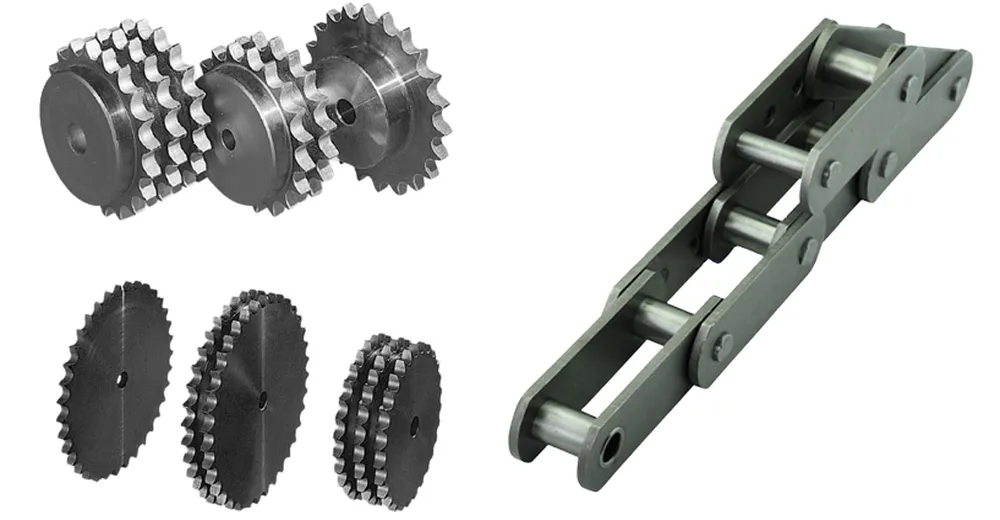

Piñones y cadenas transportadoras

Las ruedas dentadas y las cadenas transportadoras son componentes esenciales que funcionan en conjunto para garantizar un manejo uniforme y eficiente de los materiales en diversas aplicaciones industriales. La rueda dentada, una rueda dentada diseñada para engranarse con los eslabones de la cadena transportadora, impulsa el movimiento de la cadena, lo que permite un transporte controlado y preciso de los materiales a lo largo de una ruta predeterminada. Esta coordinación entre la rueda dentada y la cadena es crucial para mantener la estabilidad del sistema y una transferencia de carga eficaz.

Elegir la combinación correcta de piñón y cadena es esencial para lograr un rendimiento, una durabilidad y una distribución de carga óptimos dentro del sistema transportador. Disponibles en configuraciones simples, dobles y triples, los piñones transportadores se fabrican para satisfacer diversas necesidades operativas. La elección de los materiales, a menudo metales duraderos como acero de alta resistencia o aleaciones resistentes a la corrosión, está determinada por los requisitos de carga y factores ambientales como la temperatura y la humedad. Para aplicaciones industriales de alta carga, los piñones de acero resistentes combinados con cadenas de alta resistencia garantizan una vida útil prolongada y necesidades mínimas de mantenimiento. Además, garantizar la alineación adecuada y el mantenimiento regular reduce significativamente el desgaste, minimizando el tiempo de inactividad y mejorando la longevidad del sistema. Con la combinación correcta de piñón y cadena para transportadores, las industrias se benefician de una mayor eficiencia y un manejo confiable de los materiales.