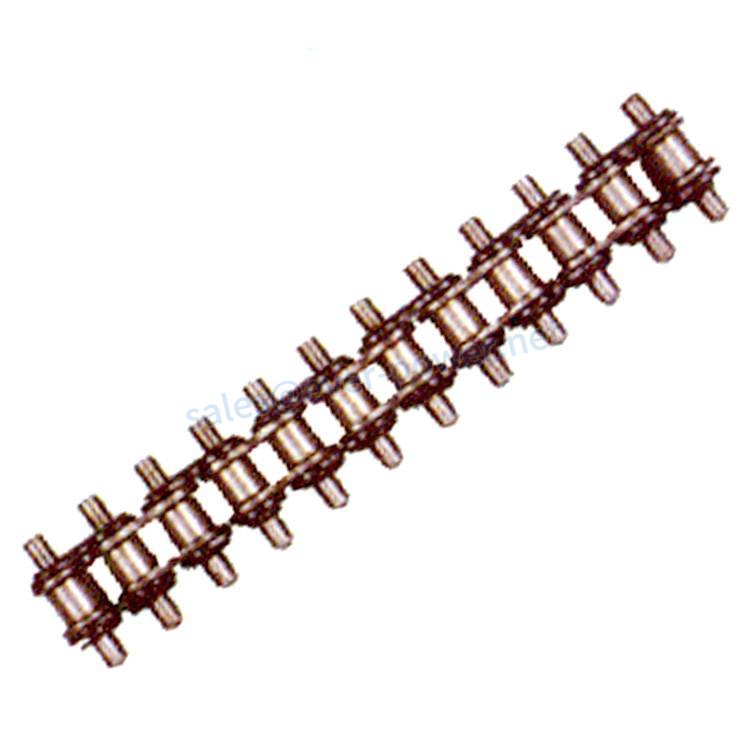

Cadena rascadora de virutas tipo bloque

Cadena raspadora de afeitado tipo bloque

La cadena raspadora de virutas tipo bloque es una herramienta esencial para diversas industrias, como la carpintería y la metalurgia. Se utiliza principalmente para eliminar virutas, polvo y pequeñas partículas de la superficie de la pieza durante el proceso de corte. Esta cadena está fabricada con materiales resistentes como el acero, lo que garantiza un rendimiento duradero. Su diseño facilita su instalación, mantenimiento, reparación y sustitución, lo que la convierte en la opción ideal para fabricantes que requieren una solución fiable y eficiente para sus procesos de producción.

Ventajas de utilizar una cadena raspadora de virutas tipo bloque

- Eliminación eficiente de virutas: la cadena está diseñada para eliminar de manera eficaz y eficiente las virutas y otras partículas de la superficie de la pieza de trabajo, lo que garantiza un producto terminado de alta calidad.

- Duradero y de larga duración: la cadena raspadora de afeitar tipo bloque está hecha de materiales de alta calidad como acero, lo que garantiza su rendimiento duradero incluso en condiciones difíciles.

- Fácil de instalar y mantener: la cadena se puede instalar, mantener y reparar fácilmente, lo que reduce el tiempo de inactividad y aumenta la productividad.

- Aplicaciones flexibles: La cadena se puede utilizar en diversas industrias, incluida la carpintería y la metalurgia, lo que la convierte en una solución versátil para los fabricantes.

Cómo instalar, mantener y reparar la cadena raspadora de afeitado tipo bloque

La instalación de una cadena de raspador de virutas tipo bloque es un proceso sencillo. Se recomienda seguir las instrucciones del fabricante para una instalación correcta. Para mantener el rendimiento de la cadena, es fundamental limpiarla y lubricarla regularmente. Cualquier pieza dañada o desgastada debe repararse o reemplazarse de inmediato para evitar daños mayores. En caso de dificultad durante la reparación o el reemplazo, los fabricantes deben buscar asistencia profesional para garantizar el rendimiento óptimo de la cadena.

Preguntas y respuestas

P1. ¿Cuál es la principal aplicación de la cadena raspadora de virutas tipo bloque?

A1. La aplicación principal de la cadena raspadora de virutas tipo bloque es eliminar virutas, polvo y pequeñas partículas de la superficie de la pieza de trabajo durante el proceso de corte.

P2. ¿De qué material está hecha la cadena raspadora de virutas tipo bloque?

A2. La cadena raspadora de afeitar tipo bloque está fabricada con materiales resistentes como el acero, lo que garantiza un rendimiento duradero.

Q3. ¿Cómo se instala la cadena?

A3. La instalación de la cadena raspadora de virutas tipo bloque es sencilla. Se recomienda seguir las instrucciones del fabricante para una instalación correcta.

P4. ¿Qué se debe hacer para mantener el rendimiento de la cadena?

A4. Para mantener el rendimiento de la cadena, es fundamental limpiarla y lubricarla regularmente. Cualquier pieza dañada o desgastada debe repararse o reemplazarse de inmediato para evitar daños mayores.

P5. ¿Qué industrias pueden utilizar la cadena raspadora de tipo bloque?

A5. La cadena raspadora de virutas tipo bloque se puede utilizar en diversas industrias, como la carpintería y la metalurgia, lo que la convierte en una solución versátil para los fabricantes.

En nuestra empresa, nos especializamos en el suministro de diversos engranajes de plástico utilizados en la industria, incluyendo cajas de engranajes agrícolas, ejes de salida de potencia, ruedas dentadas, acoplamientos hidráulicos, reductores de tornillo sin fin, engranajes y cremalleras, cadenas desmontables, poleas, reductores planetarios, poleas de distribución, bujes y más. Nos comprometemos a ofrecer productos de alta calidad, precios competitivos y un servicio atento a nuestros clientes, y les damos la bienvenida para que nos contacten si buscan soluciones personalizadas.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios