Cadenas combinadas de hierro fundido de clase C C188CP

Introduction to C Class Cast Iron Combination Chains C188CP

C Class Cast Iron Combination Chains C188CP, manufactured by HZPT, are extensively used for elevating and conveying a wide variety of abrasive and non-abrasive materials. These chains are not recommended for drive chain applications. The combination links of these chains are symmetrical, allowing them to be operated in either direction of travel.

C Class Cast Iron Combination Chains C188CP Specifications

Dimensions:

- Pitch (P): 2.609 inches

- Overall Width - Cottered (C2): 2.69 inches

- Diameter of Pin (E): 0.500 inches

- Overall Width - Riveted (C1): 2.50 inches

- Height of Sidebar (H): 1.12 inches

- Diameter of Barrel (H): 0.88 inches

- Head of Pin to Center Line (J): 1.25 inches

- End of Pin to Center Line - Cottered (K): 1.44 inches

- End of Pin to Center Line - Riveted (L): 1.25 inches

- Thickness of Sidebar (T): 0.25 inches

- Max. Allowable Sprocket Face (A): 0.94 inches

- Overall Length of Barrel (X): 1.56 inches

Strength and Load Capacity:

- Avg. Ultimate Strength: 18,900 lb

- Max. Recommended Working Load: 2,350 lb

- Links per 10': 46

- Weight per 10': 3.6 lb

- Sidebars (Outside Links): Carbon Steel, Heat Treated

- Avg. Plain Block Link Weight: 0.7 lb

- Avg. Steel Pin with Cotter Weight: 0.2 lb

- Avg. Steel Rivet Weight: 0.2 lb

- Attachment Available: F2, G6, K1, K2, S1

Nota:

- Alternating pin heads are standard; they can be supplied on the same side if specified.

- Available in riveted and cottered construction. Cottered will be furnished unless riveted is requested.

Cast Combination Chain Features

A cast combination chain combines strength, ductility, and wear resistance. The HZPT cast combination chain is a durable and highly efficient solution for conveyor and drag applications. These chains are manufactured with pearlitic malleable iron block links, providing exceptional wear resistance and balanced toughness. They also feature stainless steel pins for corrosion resistance. The cast combination chain is a highly recommended choice for heavy-duty conveyor applications.

The steel outer links and cast inner links make up the combination chain. They are widely used for conveying applications, such as in a conveyor or an elevator. These chains are particularly suitable for abrasive materials and are less expensive than their all-steel counterparts.

Mechanical Chains and Sprockets

Chains and sprockets are mechanical devices that allow two shafts to rotate in synchronization. They can be made of steel, nylon, or Teflon. There are different types of chains and sprockets depending on the application and the material used.

When choosing a chain, refer to the chain size chart in the manual. The chain size and the pitch measurement are standardized by ANSI. Sprockets also have standardized codes that indicate the number of strands running parallel to each other.

The idler sprocket is an important part of a chain or sprocket system. It is secured to the shaft using a keyway or a set screw, according to ANSI standards. Lubrication of the chain is essential before use. The chain oil should penetrate small clearances to ensure effective lubrication.

HZPT offers a wide range of chains and sprockets for various applications. Contact us now to explore our products and services.

About HZPT

HZPT is a professional mechanical transmission parts manufacturer and supplier based in China. We specialize in various industrial plastic gears, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products, competitive prices, and excellent customer service. Customers are welcome to customize products based on their specific requirements.

Preguntas frecuentes

1. What are the advantages of C Class Cast Iron Combination Chains C188CP?

- C Class Cast Iron Combination Chains C188CP offer exceptional wear resistance and toughness due to their pearlitic malleable iron block links.

- They have stainless steel pins that provide corrosion resistance.

- These chains are highly recommended for heavy-duty conveyor applications.

2. What materials are available for these combination chains?

C Class Cast Iron Combination Chains C188CP are made of carbon steel with heat treatment for the sidebars (outside links).

3. How should I install and maintain these combination chains?

- Install the chains according to the manufacturer's guidelines and make sure they are properly tensioned.

- Regularly inspect the chains for any signs of wear, damage, or misalignment.

- Keep the chains lubricated with suitable chain oil to ensure smooth operation and prevent excessive wear.

4. Can these combination chains be replaced easily?

Yes, C Class Cast Iron Combination Chains C188CP can be replaced when necessary. Follow the installation and replacement instructions provided by the manufacturer.

5. Are these combination chains compatible with different attachments?

Yes, these chains have various attachment options, including F2, G6, K1, K2, and S1, providing flexibility for different applications.

Autor: lmc

**Disclaimer:**

The content of this page is sourced from the internet and is provided for reference purposes only. Our products are accessories and not original spare parts. We are not the holder of the original trademark mentioned in the content. Our accessories are designed to perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

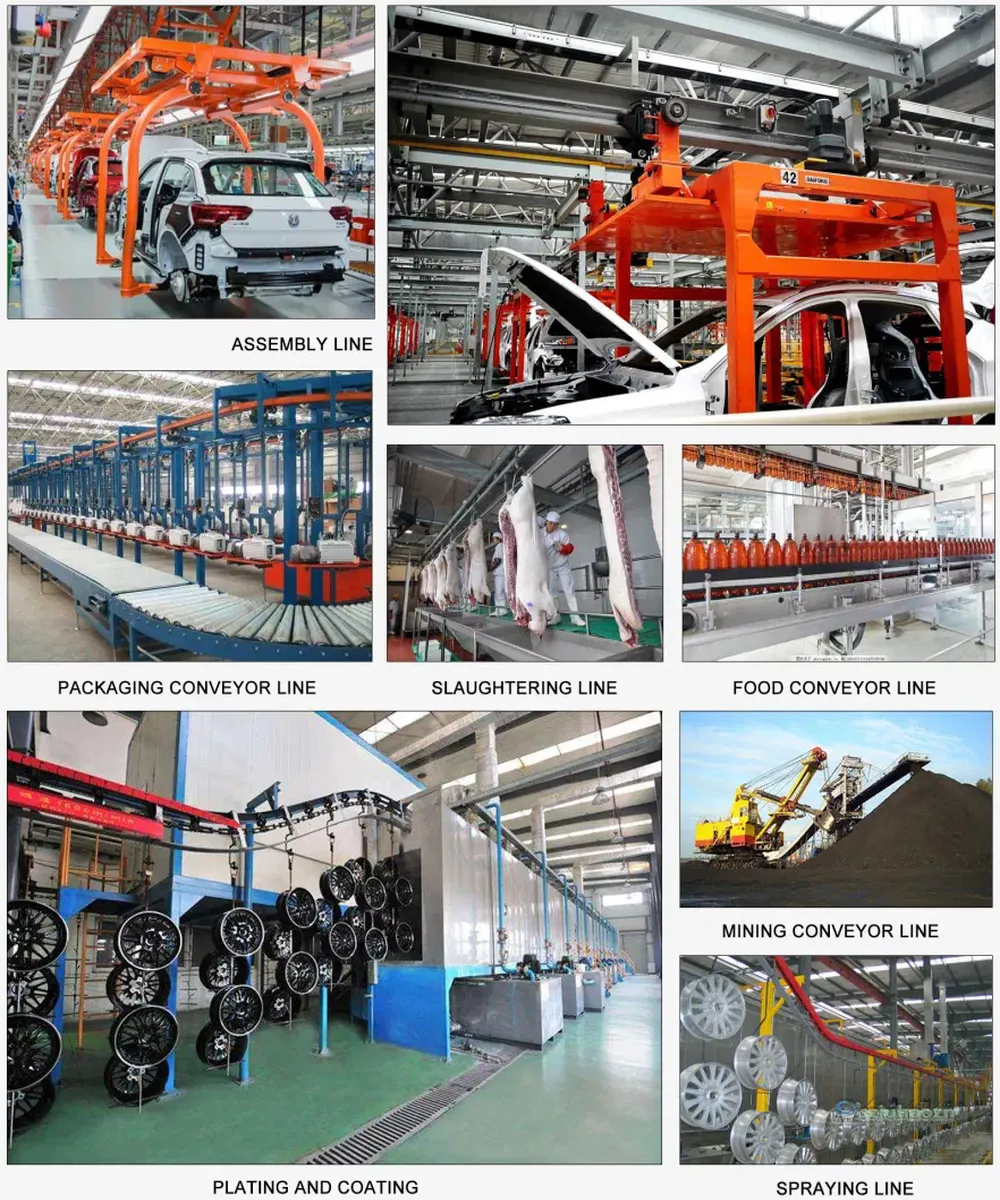

Industrias a las que prestamos servicios