Piñones de cadena ecológicos

Piñones de cadena ecológicos

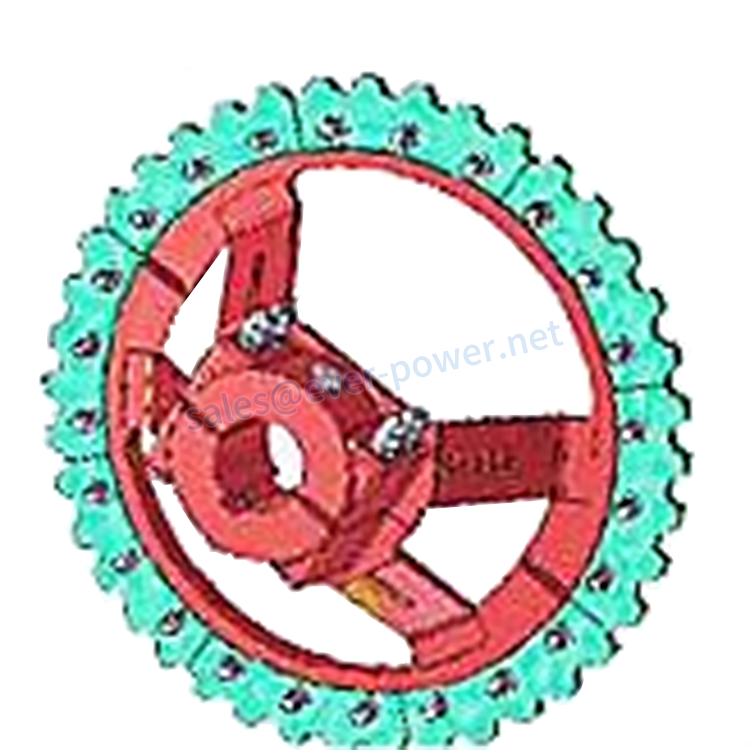

The environmental chain sprockets are a crucial component in various industrial applications. These sprockets are designed to provide efficient power transmission and smooth operation in environmentally sensitive conditions. They are available in different configurations to suit specific requirements.

Historial y clasificación del producto

The history of chain sprockets dates back to the early industrial revolution when they were used in machinery to transmit motion and power. Over the years, they have evolved to meet the demands of modern industries. Environmental chain sprockets can be categorized into different types based on their construction and materials:

- Non-metallic - Made from nylon materials or UHMW-PE with stainless steel hardware

- Combination - Features a cast iron body with UHMW segmented teeth

- Piñones partidos

- Conjuntos de pasadores de corte

- Piñones cóncavos (desplazados)

- Piñones y ruedas de tracción para cribas móviles (cuerpos y dientes de repuesto)

Ventajas de los piñones de cadena ecológicos

Environmental chain sprockets offer several advantages in industrial applications:

- Highly durable and resistant to wear

- Excellent chemical resistance

- Low friction and noise levels

- Resistente a la corrosión

- Can operate efficiently in harsh environments

Materiales del producto

These sprockets are manufactured using high-quality materials to ensure their reliability and longevity. Some common materials used include:

- Nylon

- UHMW-PE (Ultra-High Molecular Weight Polyethylene)

- Hierro fundido

- Acero inoxidable

Usage Scenarios and Installation

Environmental chain sprockets find applications in various industries, including wastewater treatment, mining, food processing, and more. They are commonly used in:

- Sistemas transportadores

- Sistemas de transmisión de potencia mecánica

- Water treatment plants

- Maquinaria industrial

Installing these sprockets requires careful consideration of alignment and proper tensioning. It is crucial to follow the manufacturer's guidelines for installation to ensure optimal performance.

Mantenimiento y reparación

To maintain the functionality and extend the lifespan of environmental chain sprockets, regular maintenance is essential. Some recommended maintenance practices include:

- Regular lubrication

- Inspection for wear and damage

- Tension adjustment

- Replacing worn-out or damaged components

When repairs are needed, it is recommended to consult a professional or contact the original supplier for guidance.

Reemplazo de producto

Over time, environmental chain sprockets may require replacement due to wear or changes in operational requirements. When replacing the sprockets, it is crucial to consider the specifications and compatibility with the existing system. Consulting the original supplier for guidance is recommended to ensure the proper selection and installation of replacement sprockets.

Otros negocios de productos de la empresa

Aside from environmental chain sprockets, our company specializes in providing a wide range of industrial plastic gears and related accessories. Our product offerings include:

- Cajas de cambios agrícolas

- Ejes de salida de potencia

- Acoplamientos hidráulicos

- Reductores de engranajes helicoidales

- Cremalleras

- Cadenas desmontables

- Poleas y poleas

- Cajas de engranajes planetarios

- Poleas de distribución

- Bujes

We take pride in offering high-quality products at competitive prices. Our dedicated team ensures outstanding customer service and welcomes customization requests based on specific needs. Feel free to contact us with any inquiries or requests.

Preguntas frecuentes

Q1: Can environmental chain sprockets be used in corrosive environments?

A1: Yes, environmental chain sprockets are designed to be corrosion-resistant and can operate efficiently in corrosive environments.

Q2: What is the recommended maintenance frequency for these sprockets?

A2: Regular maintenance, including lubrication and inspection, should be performed as per the manufacturer's recommendations. The frequency may vary depending on the operating conditions.

Q3: Are environmental chain sprockets compatible with different chain types?

A3: Yes, environmental chain sprockets are available in various tooth profiles and sizes to accommodate different chain types.

Q4: Can damaged sprocket teeth be repaired?

A4: In most cases, damaged sprocket teeth cannot be repaired. It is recommended to replace the entire sprocket or consult a professional for further evaluation.

Q5: Are these sprockets suitable for high-speed applications?

A5: Yes, environmental chain sprockets are designed to handle high-speed applications while maintaining optimal performance and reliability.

Autor: lmc

Disclaimer: All the content on this page is sourced from the internet and is intended only as a reference for product selection. Our products are aftermarket accessories and not original spare parts. We do not hold the original trademark of the content. Our accessories perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios