EPG30 NACM96 Self Color Link Chain

Stainless Steel Link Chain: History, Classification, Advantages, Materials, Installation, Maintenance, and Repair

Stainless steel link chains are used for a wide range of applications, including lifting, transport, and decoration purposes. They are durable and can withstand heavy loads. The history of link chains dates back to ancient times, where they were used for various purposes. Link chains have since evolved, and there are now many different types and grades available.

Clasificación

Stainless steel link chains are classified according to their size, grade, and finish. They are available in various sizes, from 7 to 22 mm, and in different grades and finishes.

Ventajas

One of the main advantages of stainless steel link chains is their durability. They are made of high-quality low-carbon alloy steel and can withstand heavy loads. They are also resistant to corrosion and can be used in harsh environments. Stainless steel link chains are also relatively inexpensive compared to other types of chains.

Materiales

Stainless steel link chains are made of high-quality low-carbon alloy steel. The steel is melted and then poured into molds to create the links. The links are then shaped and polished to create the finished chain.

Instalación, mantenimiento y reparación

Stainless steel link chains are easy to install and maintain. They should be lubricated regularly to prevent rust and corrosion. If a link is damaged, it can be easily replaced. To replace a link, simply remove the damaged link and replace it with a new one.

Escenarios de uso

Stainless steel link chains are commonly used in lifting and transport applications. They are also used for decoration purposes and are often seen in jewelry. Their durability makes them ideal for outdoor applications, such as in marine environments.

Preguntas y respuestas

Q: What is the maximum load capacity of a stainless steel link chain?

A: The maximum load capacity of a stainless steel link chain depends on its size and grade. Please refer to the manufacturer's specifications for load capacity information.

Q: How do I install a stainless steel link chain?

A: Stainless steel link chains are easy to install. Simply attach the chain to the object you wish to lift or secure.

Q: Can a damaged link be repaired?

A: No, a damaged link cannot be repaired. You must replace the damaged link with a new one.

Q: Can I use a stainless steel link chain in a marine environment?

A: Yes, stainless steel link chains are ideal for use in marine environments because they are resistant to corrosion.

Q: What is the difference between a stainless steel link chain and a galvanized chain?

A: The main difference between the two is that a stainless steel link chain is more durable and resistant to corrosion than a galvanized chain.

Otros productos

Our company supplies various industrial plastic gears, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. Our products are of high quality and are available at competitive prices. We offer thoughtful services and welcome customers to customize their orders with pictures and samples.

*All content on this page comes from the internet and is only used as a reference for product selection. Our products are accessories, not original spare parts. We are not the holder of the original trademark of the content. Our accessories can perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory to purchase.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

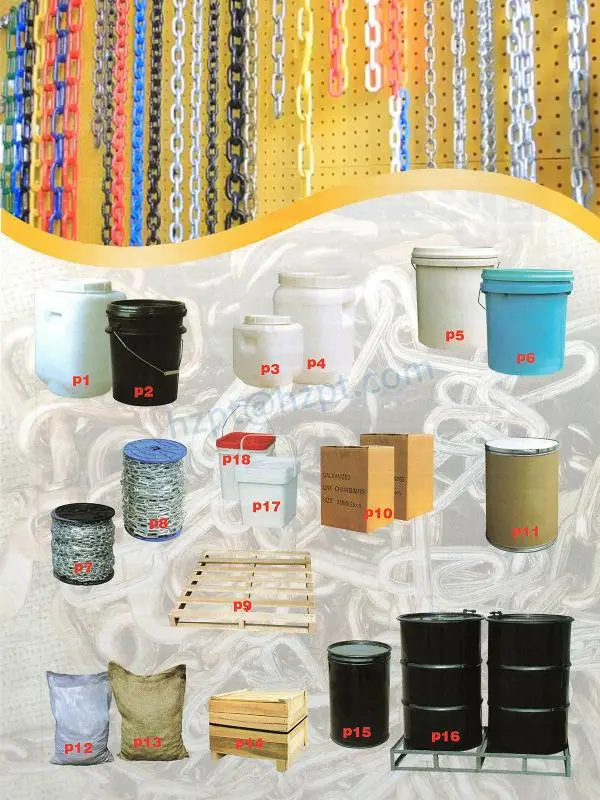

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios