Cajas de engranajes para segadoras de mayales: reemplazo del código Comer T-290A 1:1.86

La caja de engranajes de la desbrozadora de mayales T-290A, diseñada por TEBSA en Argentina, es una máquina potente para tareas de corte exigentes. Transmite la potencia desde la toma de fuerza del tractor a las cuchillas de la desbrozadora, cortando hierba espesa, maleza y matorrales en terrenos accidentados como la pampa argentina. Desde 1997, TEBSA fabrica cajas de engranajes agrícolas confiables con garantía de calidad 100%, y la T-290A no es la excepción: está diseñada para un alto par motor y un rendimiento duradero.

Esta caja de engranajes cuenta con una robusta carcasa GG25 de hierro fundido que protege sus componentes internos de las duras condiciones del campo. En su interior, engranajes de alta resistencia y cojinetes de precisión garantizan una transferencia de potencia suave y durabilidad bajo cargas intensas. Ya sea que esté desbrozando pastizales en Córdoba o manteniendo huertos en Mendoza, el T-290A ofrece eficiencia y robustez a un precio similar al del 50% en comparación con las marcas originales.

La T-290A reemplaza directamente a la Comer Code T-290A, lo que la convierte en la opción predilecta para agricultores y contratistas que buscan actualizar sus desbrozadoras de mayales. Su diseño inteligente y robusta construcción la hacen ideal para las diversas necesidades agrícolas de Argentina, desde campos de soja hasta viñedos.

Especificaciones de la caja de engranajes de la segadora de mayales T-290A (1:1.86)

| Descripción |

Cajas de engranajes para segadoras de mayales: reemplazo de la caja de engranajes Comer T-290A 1:1.86

|

|---|---|

| Solicitud |

|

| Consiste en |

|

| Información técnica |

|

| Par de salida máximo |

175,9 daNm

|

| Contiene aceite |

No

|

| Capacidad máxima de aceite |

2,3 litros

|

| Intervalo máximo de cambio de aceite |

500 horas

|

| Grado de viscosidad SAE del aceite |

80W-90

|

| Material de la carcasa |

Hierro fundido GG25

|

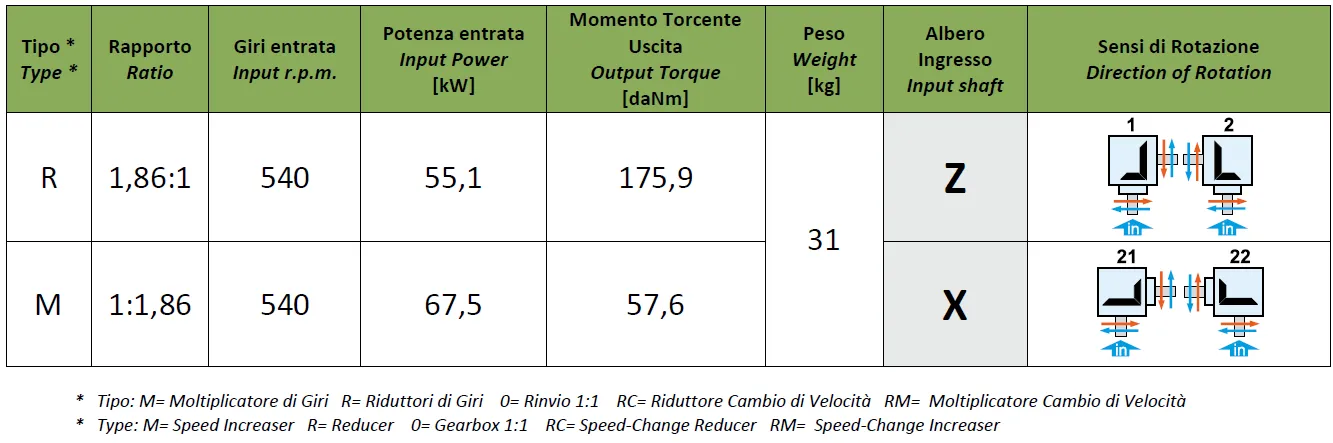

| Peso |

30 kilos

|

| Disposición de engranajes creciente |

25 - 26

|

| Disposición de engranajes Reductor |

5 - 6

|

| Potencia de entrada kW/HP Creciente |

62,5 / 85 kW/CV

|

| Eje de entrada creciente |

incógnita

|

| Reducción del eje de entrada |

O

|

| Potencia de entrada KW / HP Reductor |

55,1 / 75 kW/CV

|

| Par de salida DaNm en aumento |

57,6 daNm

|

| Relación creciente |

1:1.86

|

| Reducción de la relación |

1.86:1

|

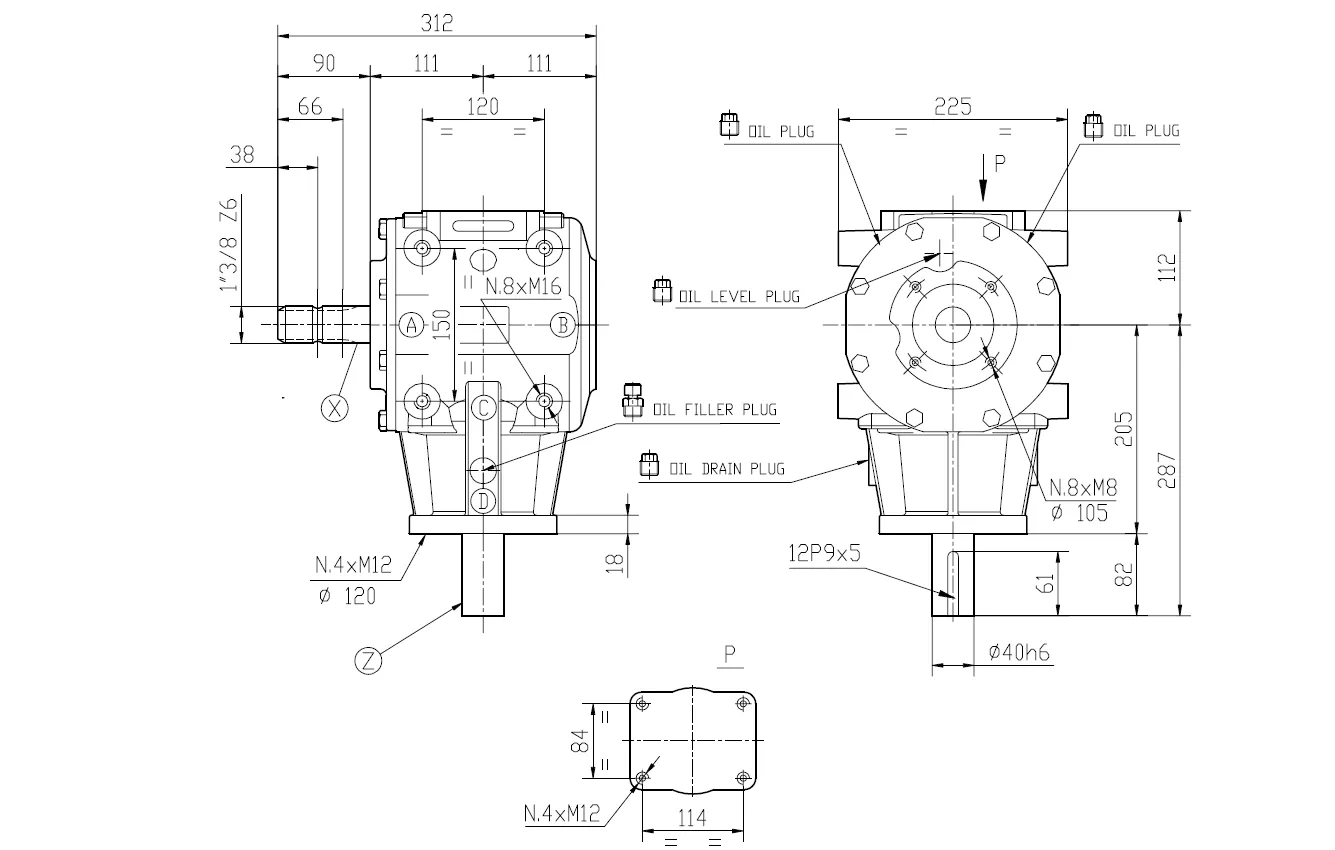

| Eje X |

1 3/8" (6) (A)

|

| Eje Y |

1 3/8" (6) (A)

|

| Eje Z |

1 3/8" (6) (B)

|

¿Por qué elegir la caja de engranajes para segadora de mayales T-290A?

La caja de engranajes de la desbrozadora de mayales T-290A es ideal para agricultores y contratistas en Argentina que realizan trabajos de siega difíciles. Por eso es una opción inteligente:

Manejo de alto par: con un par de salida máximo de 175,9 daNm, avanza a través de vegetación densa como malezas o matorrales, perfecto para limpiar terrenos para la siembra de soja o trigo.

Construcción duradera: Los engranajes forjados y la carcasa de hierro fundido GG25, tratados con procesos como la carburación, garantizan su resistencia en los duros campos de Argentina.

Funcionamiento suave: Los cojinetes de precisión reducen la fricción, manteniendo la caja de cambios funcionando sin problemas incluso durante largas horas en los pastos de Buenos Aires.

Ahorro de costes: TEBSALa ventaja de costo del 50% sobre las marcas originales significa que obtiene el máximo rendimiento sin gastar una fortuna.

Fácil mantenimiento: diseñado para cambios de aceite rápidos (cada 500 horas) y piezas accesibles, respaldado por nuestro equipo de soporte las 24 horas.

Relaciones versátiles: ofrece relaciones de aumento de 1:1,86 y de reducción de 1,86:1, lo que le permite ajustar el rendimiento para diferentes cultivos o terrenos.

Esta caja de cambios se adapta a las desbrozadoras de mayales de servicio pesado que se utilizan en huertos, viñedos o mantenimiento de carreteras, lo que la convierte en un socio confiable para el sector agrícola de Argentina.

Aplicaciones del T-290A en la agricultura argentina

La caja de engranajes de la desbrozadora de mayales T-290A está diseñada para las diversas necesidades agrícolas de Argentina. Impulsa desbrozadoras de mayales que trituran pasto denso, limpian maleza o trituran residuos de cultivos en campos de soja, maíz o girasol. En regiones como la Pampa o la zona vitivinícola de Mendoza, se adapta con facilidad a terrenos irregulares, garantizando cortes limpios y una preparación eficiente del terreno.

| Solicitud | Caso de uso | Beneficio |

|---|---|---|

| Manejo de pastizales | Cortando hierba espesa en los pastizales de Córdoba | Previene el crecimiento excesivo y mejora el pastoreo del ganado. |

| Acolchado de residuos de cultivos | Trituración de tallos de soja en Santa Fe | Mejora la salud del suelo, acelera la descomposición. |

| Mantenimiento de huertos | Limpieza de malezas en los viñedos de Mendoza | Protege los cultivos, reduce los hábitats de las plagas. |

| Limpieza de carreteras | Cortar la maleza en las autopistas de Buenos Aires | Mejora la visibilidad, garantiza la seguridad. |

Su potencia de entrada de 85 HP (incremental) y 75 HP (reductora) la hacen versátil para los tractores de uso común en Argentina. Ya sea agricultor o contratista que compra cajas de engranajes para desbrozadoras de mayales en línea, la T-290A ofrece un rendimiento confiable adaptado a las condiciones locales.

Consejos de mantenimiento para un rendimiento duradero

Para mantener la caja de engranajes de la segadora de mayales T-290A funcionando de manera óptima, siga estos pasos prácticos:

Revise el aceite regularmente: Use aceite 80W-90 de 2.3 litros de capacidad. Cámbielo después de las primeras 50 horas y luego cada 500 horas.

Inspeccione si hay desgaste: busque fugas o daños en la carcasa de hierro fundido durante los controles de rutina para detectar problemas de forma temprana.

Lubricar los ejes: mantenga los ejes de entrada y salida (1 3/8" 6 estrías) engrasados para garantizar una transferencia de potencia suave.

Alinee correctamente: la desalineación puede estresar los engranajes, así que asegúrese de que la caja de cambios y la cortadora de césped estén configuradas correctamente.

Utilice piezas originales: utilice componentes aprobados por TEBSA para las reparaciones para mantener nuestra garantía de calidad 100%.

Estos pasos, combinados con la experiencia de TEBSA en forjado y tratamiento térmico, garantizan que su caja de engranajes dure años de uso intensivo en los campos de Argentina.

| Tarea de mantenimiento | Frecuencia | Herramientas necesarias |

|---|---|---|

| Cambio de aceite | Cada 500 horas | Llave, cárter de drenaje de aceite |

| Lubricación del eje | Mensual | pistola de grasa |

| Inspección visual | Antes de cada uso | Linterna, trapo |

Para cualquier pregunta sobre rendimiento o configuración, nuestro equipo de ingeniería responde dentro de las 24 horas, lo que garantiza que aproveche al máximo la caja de cambios de su cortadora de mayales en Argentina.

Acerca de TEBSA y nuestras soluciones agrícolas

Desde 1997, TEBSA ha sido una marca de confianza en el sector agrícola argentino, ofreciendo cajas de engranajes de alto rendimiento con una ventaja de costo 50% sobre la competencia. Con sede en Argentina, combinamos fabricación avanzada (forja, fundición y tratamientos térmicos como la carbonitruración) con un compromiso con la calidad 100%. Con certificación ISO 9001-2015, servimos a agricultores y contratistas desde Buenos Aires hasta Mendoza con soluciones que optimizan la eficiencia y la seguridad.

Además de la caja de cambios para segadora de mayales T-290A, ofrecemos una amplia gama de cajas de cambios agrícolas, que incluyen:

Cajas de engranajes para cortadoras rotativas: como la RC-61, ideal para cortes pesados.

Cajas de engranajes para esparcidores de fertilizantes: para una distribución precisa de nutrientes.

Cajas de engranajes para cultivadores rotativos: diseñadas para la preparación del suelo en campos de soja y maíz.

Cajas de engranajes para excavadoras de postes: perfectas para cercar en las estancias de Argentina.

Ejes de toma de fuerza:Transferencia de potencia duradera para diversos implementos agrícolas.

Nuestro talentoso equipo de ingeniería, disponible las 24 horas, le acompaña desde el prototipado hasta la producción en masa. Ya sea que necesite una caja de engranajes para segadora de mayales para la venta o soluciones personalizadas para cultivos argentinos como la soja o el girasol, TEBSA es su socio de confianza. Contáctenos ¡Explore hoy nuestra gama completa y actualice su equipo!

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios