Husillo de accionamiento hidráulico EP-MDH-40 para caja de cambios

El husillo de accionamiento hidráulico EP-MDH-40, también conocido como carcasa de rodamiento, es un componente esencial de las cajas de engranajes agrícolas, diseñado para ofrecer un rendimiento robusto en aplicaciones exigentes. Fabricado por TEBSAProveedor de confianza de Argentina desde 1997, este husillo garantiza una transmisión de potencia fluida en maquinaria utilizada en los sectores agrícola, de construcción, forestal, metalúrgico y de protección ambiental. Con la garantía de calidad 100% y la ventaja de costo 50% frente a las marcas originales, el EP-MDH-40 de TEBSA está diseñado para ofrecer durabilidad y eficiencia en las diversas industrias de Argentina, desde la llanura pampeana hasta los centros industriales de Buenos Aires y Córdoba.

Fabricado con precisión, el EP-MDH-40 utiliza materiales de alta calidad como acero de aleación 20CrMnTi para engranajes y acero de aleación 42CrMo para ejes, procesados mediante técnicas avanzadas como revenido, cementado y temple. Su carcasa de hierro fundido o hierro dúctil soporta condiciones extremas, lo que lo hace ideal para tareas pesadas como la cosecha de soja o la preparación de obras. Con un diseño compacto, bajo nivel de ruido (60-68 dB) y alta eficiencia (98%), este husillo satisface las necesidades de agricultores, contratistas y operadores industriales en Argentina.

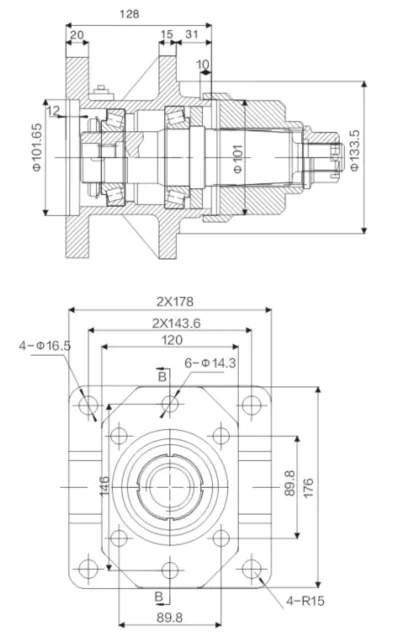

Especificaciones técnicas del husillo de accionamiento hidráulico EP-MDH-40

El EP-MDH-40 está diseñado para ofrecer precisión y fiabilidad. A continuación, se detallan sus especificaciones principales:

| Material de la carcasa | Hierro fundido/hierro dúctil |

| Dureza de la carcasa | HBS190-240 |

| Material de engranajes | Acero de aleación 20CrMnTi |

| Dureza superficial de los engranajes | HRCC58~62 |

| Dureza del núcleo del engranaje | HRCC33 ~ 40 |

| Material del eje de entrada/salida | Acero de aleación 42CrMo |

| Dureza del eje de entrada/salida | HRc25 ~ 30 |

| Precisión de mecanizado de engranajes | Rectificado preciso, grado 6~5 |

| Aceite lubricante | GB L-CKC220-460, Shell Omala220-460 |

| Tratamiento térmico | Revenido, cementado, temple |

| Eficiencia | 98% |

| Ruido (máximo) | 60 ~ 68 dB |

| Vibración | ≤20 µm |

| Reacción | ≤20 min de arco |

| Marca de rodamientos | Rodamientos de las mejores marcas de China: HRB/LYC/ZWZ/C&U, SKF, FAG, INA, NSK |

| Marca del sello de aceite | NAK (Taiwán) u otras marcas solicitadas |

Aplicaciones y beneficios del husillo de accionamiento hidráulico EP-MDH-40

El EP-MDH-40 es un componente versátil, diseñado para diversas industrias en Argentina, que ofrece un rendimiento inigualable en entornos exigentes. Sus aplicaciones abarcan la agricultura (p. ej., cosecha de soja y maíz en la Pampa), la construcción (preparación de terrenos en Buenos Aires), la silvicultura (procesamiento de madera en Misiones), el procesamiento de metales (talleres industriales en Rosario) y la protección ambiental (sistemas de gestión de residuos). A continuación, se detallan sus principales ventajas:

Alta durabilidad: Los engranajes de acero de aleación 20CrMnTi, con una dureza superficial de HRC58-62, resisten el desgaste incluso en los climas subtropicales húmedos o llanuras polvorientas de Argentina.

Transferencia de potencia eficiente: Con la eficiencia 98%, minimiza la pérdida de energía, reduciendo los costos de combustible para tractores y maquinaria.

Bajo mantenimiento: Los engranajes rectificados con precisión (grado 6-5) y los sellos de aceite NAK mantienen el mantenimiento simple, respaldado por el soporte técnico de TEBSA las 24 horas.

Funcionamiento silencioso: Los niveles de ruido de 60-68 dB garantizan un entorno de trabajo cómodo, crucial durante largas horas en el campo.

Ahorro de costos: la ventaja de costo del 50% de TEBSA hace que el EP-MDH-40 sea una actualización asequible para los agricultores y contratistas argentinos.

El EP-MDH-40 se integra perfectamente en cajas de cambios agrícolas, mejorando el rendimiento de maquinaria como desbrozadoras rotativas, desbrozadoras de mayales y cultivadores. Su diseño robusto soporta un alto par y cargas pesadas, lo que la convierte en una opción confiable para tareas como la limpieza de pastizales o el procesamiento de componentes metálicos.

Casos de uso específicos de la aplicación

Para ilustrar su versatilidad, así es como el EP-MDH-40 sirve a diferentes sectores:

| Industria | Solicitud | Beneficio |

|---|---|---|

| Agricultura | Cosecha de soja en Córdoba | Alto par para el corte de cultivos pesados |

| Construcción | Desalojo de terrenos en Buenos Aires | La carcasa duradera resiste el impacto de los escombros. |

| Silvicultura | Procesamiento de madera en Misiones | Baja vibración para un corte de precisión |

Características técnicas y mantenimiento del EP-MDH-40

El EP-MDH-40 destaca por su ingeniería avanzada, diseñada para satisfacer las necesidades de la industria argentina. Sus principales características técnicas incluyen:

Excelencia del material: Los engranajes fabricados en acero de aleación 20CrMnTi y los ejes en 42CrMo garantizan resistencia y resistencia a la corrosión, vitales para los variados climas de Argentina.

Ingeniería de precisión: El rectificado preciso (grado 6-5) y el juego reducido (≤20 Arcmin) brindan un funcionamiento suave, lo que reduce el desgaste de los componentes conectados.

Tratamiento térmico: Procesos como la cementación y el temple mejoran la dureza del engranaje (HRC58-62) y la tenacidad del núcleo (HRC33-40), ideal para tareas de alta carga.

Componentes de primer nivel: Los rodamientos de marcas confiables como SKF, FAG o HRB/LYC de China, combinados con sellos de aceite NAK, garantizan confiabilidad a largo plazo.

Lubricación: Compatible con aceites GB L-CKC220-460 o Shell Omala220-460, manteniendo el rendimiento en condiciones extremas.

Para mantener el EP-MDH-40 en óptimas condiciones, siga estos consejos de mantenimiento:

Inspecciones regulares: Verifique si hay fugas de aceite o daños en la carcasa cada 500 horas de funcionamiento.

Cambios de aceite: Reemplace el aceite lubricante cada 1000 horas o 410~420 horas, utilizando aceites aprobados por TEBSA como Shell Omala 220-460.

Controles de cojinetes: inspeccione los cojinetes para detectar desgaste durante el mantenimiento anual para evitar tiempos de inactividad inesperados.

Alineación: Asegúrese de que la alineación sea adecuada con la caja de cambios para evitar vibraciones o desgaste de los engranajes.

Limpieza: Mantener el huso libre de residuos, especialmente en regiones polvorientas como la Pampa.

Siguiendo estos pasos, los operadores argentinos pueden extender la vida útil del EP-MDH-40, garantizando un rendimiento confiable durante años.

Programa de mantenimiento

Para mayor claridad, a continuación se presenta un programa de mantenimiento recomendado:

| Tarea | Frecuencia |

|---|---|

| Inspeccionar si hay fugas o daños | Cada 500 horas |

| Cambiar el aceite lubricante | Cada 1.000 horas |

| Comprobar los cojinetes | Anualmente |

Acerca de TEBSA y nuestras soluciones agrícolas

Desde 1997, TEBSA, con sede en Argentina, ha sido un fabricante líder de componentes agrícolas e industriales, ofreciendo soluciones confiables y rentables a nivel mundial. Nuestro compromiso con la garantía de calidad 100%, el ahorro de costos 50% en comparación con las marcas originales y un equipo de ingeniería receptivo (con respuesta las 24 horas) nos convierte en un socio de confianza para agricultores, contratistas y operadores industriales. Con certificación ISO 9001-2015, utilizamos procesos de fabricación avanzados como forjado, tratamiento térmico y rectificado de precisión para producir productos duraderos a la medida de las necesidades únicas de Argentina, desde campos de soja en Córdoba hasta obras de construcción en Buenos Aires.

Además del husillo de accionamiento hidráulico EP-MDH-40, TEBSA ofrece una amplia gama de cajas de engranajes y componentes agrícolas, que incluyen:

Cajas de engranajes para cortadoras rotativas: como la RC-61, ideal para cortes pesados en el manejo de pasturas.

Cajas de engranajes para esparcidores de fertilizantes: para una distribución precisa en el cultivo de cultivos.

Cajas de engranajes para segadoras de mayales: para un corte versátil en los variados terrenos de Argentina.

Cajas de engranajes para excavadoras de postes: para cercas y plantaciones eficientes.

Ejes TDF: para una transferencia de potencia confiable en tractores e implementos.

Nuestros productos están diseñados para soportar los desafiantes ambientes de Argentina, desde regiones subtropicales húmedas hasta llanuras áridas, garantizando máxima productividad y seguridad. Contacto Llámenos hoy mismo a TEBSA para explorar nuestro catálogo completo o solicitar una cotización para el EP-MDH-40 u otras soluciones.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios