Ordinary Medium Link Chain

Ordinary Medium Link Chain

The ordinary medium link chain is a type of chain that consists of multiple interconnected links. Each link is connected by retaining members and has a pair of rollers at its ends that mate with pivots. The external link pivots on pivot 28, while the inner link pivots on auxiliary pivot 28. Auxiliary pivot pins are connected to the inner links by T-section posts 31 protruding from the frame 19.

Regular chains are typically made of low-grade carbon steel and come in various link sizes. They are commonly used in industrial, marine, and agricultural applications. These chains are available in unmarked and tested varieties, and they come in different link diameters and finishes, including yellow, blue, and galvanized.

A barbed chain is a type of ordinary long chain that consists of two side limb sections and a curved bridge. The two side limb sections meet at one end and cross at the other. The curved bridge section eliminates the need for welding, which helps reduce production costs.

Each link in a barbed chain is made from two separate side pieces connected by a U-shaped bridge section at their ends. The link ends at the point where the crossbar 60 projects in the opposite direction. Barbed chains are commonly used in agriculture and are called "barbed chains" because they have spikes on their edges that act as spikes when the chain spins behind a tractor.

What is the Strongest Link in a Chain?

The strength of a chain is determined by its weakest link. Each link in a chain has a different intensity, and if the weakest link breaks, the entire chain becomes useless. To test the strength of a chain, a single link is broken. If a chain contains 100 links and one of them is weak, the entire chain will be compromised. Standard grade chains can be enhanced for specific applications. For demanding maritime applications, heat-treated chains are used, such as tuna nets and scallop chains.

Thicker links are generally the strongest in a chain because they have no bending points. These chains are also more resistant to damage and can withstand greater exposure. Different types of chains, such as cable chains and wheat chains, have their own strengths and flexibility characteristics.

How to Design a Link Chain

Designing a link chain requires careful consideration of various factors. Here are some tips to help you select and design the perfect link chain for your needs.

1. Choose a chain made of durable material, preferably one that is resistant to wear and suitable for long-term use.

2. Consider the style and design of the chain. For example, a thin white gold chain may be less suitable for a statement necklace, while a chunky yellow gold chain can be perfect for a casual day. Paper clip chains are ideal for everyday office wear and casual attire.

3. Match the chain design to the garment or overall aesthetic. Classic mooring chains consist of small oval or circular links connected by welded circular links, while curb chains have clasps connecting the ends of the chain.

Piñones relacionados

Properly installed sprockets play a vital role in increasing the efficiency and load-carrying capacity of chain-driven motion systems. When selecting a sprocket, it's important to consider the size and type of fit for your specific system.

Sprocket life can vary depending on factors such as riding style, conditions, chain pitch and size, and maintenance routine. Steel sprockets with hardened teeth can significantly increase their lifespan, often tripling it.

Sprockets are toothed wheels that mesh with a chain during rotation. They are commonly used in various applications, from bicycles to motor vehicles.

Nuestra ventaja

- Productos de alta calidad a precios competitivos.

- Amplia variedad de productos disponibles en diversos materiales y tamaños.

- Nuestros productos se fabrican en una fábrica con certificación ISO9001:2008

- Great customer service that's here to answer all of your questions

- La mayor selección en línea de productos de transmisión de potencia

- Productos de alta calidad hechos a medida.

Preguntas y respuestas

P: ¿Cuál es la fortaleza de su empresa?

A: We have an experienced engineering team that can provide solutions for product and machine designs.

Q: How about your quality?

A: We have a professional factory and skilled workers, ensuring the quality of our products surpasses that of our competitors.

P: ¿Cuál es su MOQ?

A: Our minimum order quantity is one piece.

Q: Could you produce a customized product according to

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

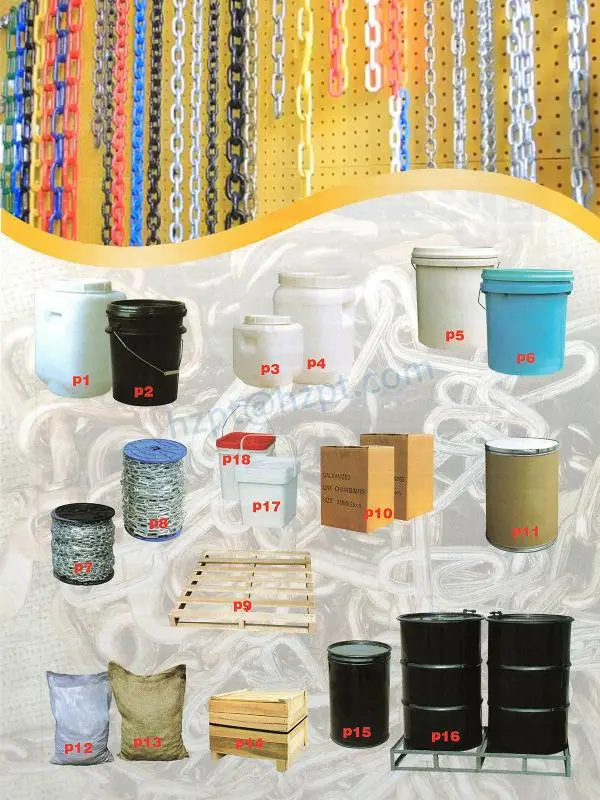

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios