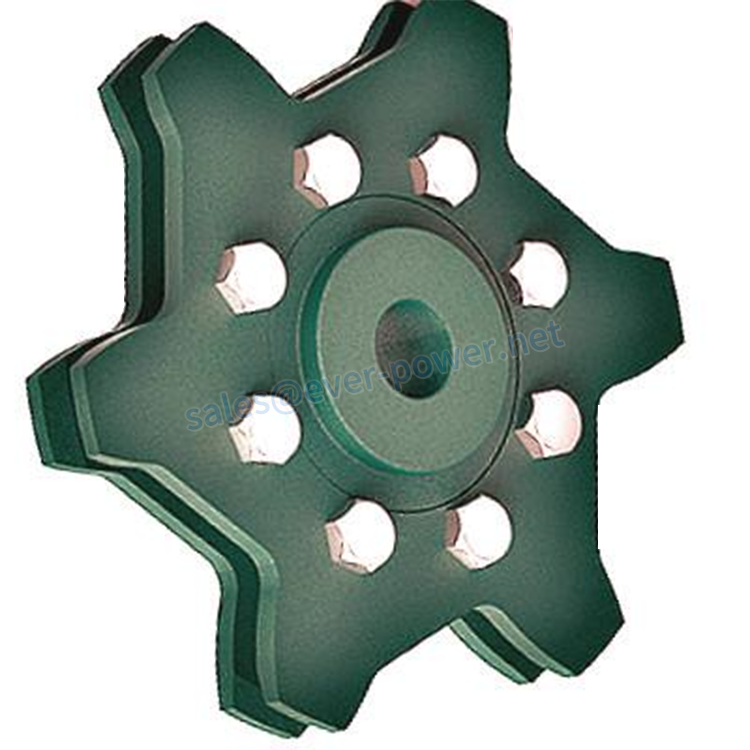

Piñón de cadena rascador

Aplicaciones y ventajas de los piñones de cadena rascadora

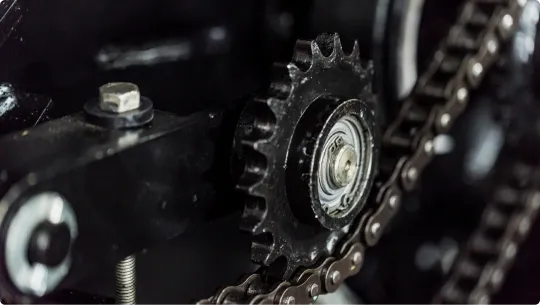

Las ruedas dentadas para cadenas rascadoras son un componente esencial en diversas aplicaciones industriales. Se emplean en sistemas transportadores, elevadores y otros equipos pesados para transferir potencia o movimiento entre dos ejes paralelos. Estas ruedas se utilizan principalmente en aplicaciones donde se requiere transferir cargas pesadas con suavidad y precisión.

Estos piñones se fabrican con materia prima de alta calidad bajo la atenta supervisión de nuestro experto equipo, cumpliendo con los parámetros establecidos por la industria. Se fabrican con materia prima de alta calidad para garantizar su ausencia de errores. Su construcción robusta y acabado liso garantizan una mayor vida útil con un mantenimiento mínimo.

Historia y clasificación de los piñones de cadena rascadora

La historia de las ruedas dentadas se remonta a principios del siglo XX, durante la revolución industrial. Se inventaron ante la necesidad de una transmisión de potencia más precisa y fluida. Desde entonces, han experimentado numerosos cambios y avances para satisfacer las crecientes demandas de diversas industrias.

Las ruedas dentadas para cadena rascadora se clasifican en varios tipos según su diseño, paso y material. Los tipos más comunes son las ruedas dentadas simples, dobles y triples. También se clasifican según el número de dientes, el tamaño del orificio y el diámetro primitivo.

Ventajas de las ruedas dentadas de cadena rascadora

Los piñones de cadena rascadores tienen numerosas ventajas, tales como:

- Alta capacidad de carga

- Transmisión de potencia precisa y suave

- Larga vida útil con bajo mantenimiento.

- Resistencia a la corrosión y al desgaste.

- Sin deslizamiento durante el funcionamiento

Materiales disponibles e instalación

Las ruedas dentadas de la cadena rascadora se fabrican con diferentes materiales, como acero, hierro fundido y plástico. El material utilizado depende de la aplicación y la capacidad de carga requerida.

La instalación de estos piñones es relativamente sencilla y se puede realizar con herramientas básicas. Es fundamental mantenerlos limpios y sin residuos, ya que cualquier acumulación puede provocar un mal funcionamiento.

Mantenimiento y reparación

El mantenimiento adecuado de los piñones de la cadena rascadora es crucial para garantizar su longevidad y buen funcionamiento. Se recomienda limpiarlos y lubricarlos regularmente para evitar el desgaste y la corrosión. En caso de daños o mal funcionamiento, se recomienda reemplazar el piñón inmediatamente para evitar daños adicionales al equipo.

Otros productos ofrecidos por nuestra empresa

En nuestra empresa, ofrecemos una amplia gama de engranajes plásticos industriales, como cajas de engranajes agrícolas, ejes de salida de potencia, acoplamientos hidráulicos, reductores de tornillo sin fin, cremalleras, cadenas desmontables, poleas, reductores planetarios, poleas de distribución y bujes. Nuestros productos son de alta calidad y los ofrecemos a precios competitivos para satisfacer las necesidades de nuestros clientes. Invitamos a nuestros clientes a personalizar sus productos con imágenes y muestras.

Preguntas frecuentes (FAQ)

P1. ¿Qué son los piñones de cadena rascadora?

Las ruedas dentadas de cadena rascadora son un componente esencial en diversas aplicaciones industriales. Se emplean principalmente en sistemas transportadores, elevadores y otros equipos pesados para transferir potencia o movimiento entre dos ejes paralelos.

P2. ¿Cuáles son las ventajas de utilizar piñones de cadena rascadores?

Las ruedas dentadas de cadena rascadora tienen numerosas ventajas, como alta capacidad de carga, precisión y transmisión de potencia suave, larga vida útil con bajo mantenimiento, resistencia a la corrosión y al desgaste, y sin deslizamiento durante el funcionamiento.

P3. ¿Qué materiales se utilizan para fabricar las ruedas dentadas de la cadena rascadora?

Las ruedas dentadas de la cadena rascadora se fabrican con diferentes materiales, como acero, hierro fundido y plástico. El material utilizado depende de la aplicación y la capacidad de carga requerida.

P4. ¿Cómo se deben mantener los piñones de la cadena rascadora?

El mantenimiento adecuado de los piñones de la cadena rascadora es crucial para garantizar su longevidad y buen funcionamiento. Se recomienda limpiarlos y lubricarlos regularmente para evitar el desgaste y la corrosión.

P5. ¿Qué otros productos ofrece su empresa?

En nuestra empresa ofrecemos una amplia gama de engranajes plásticos industriales como cajas de engranajes agrícolas, ejes de salida de potencia, acoplamientos hidráulicos, reductores de tornillo sin fin, cremalleras, cadenas desmontables, poleas y poleas, cajas de engranajes planetarios, poleas de distribución y bujes.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios