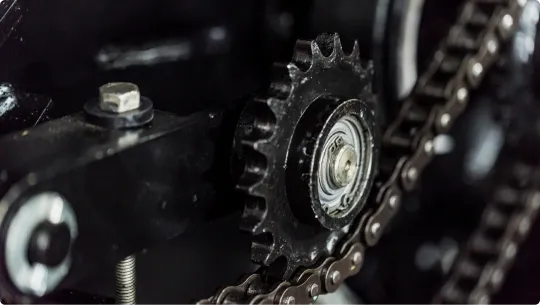

Piñones para cadena transportadora de caja forjada

Piñones para cadena transportadora de caja forjada

A sprocket is a crucial component in the operation of a forged case conveyor chain. It is responsible for transferring power from the motor to the chain, ensuring smooth and efficient movement of materials. At [Company Name], we offer a wide range of high-quality sprockets designed specifically for forged case conveyor chains.

Escenarios de uso común

Our sprockets for forged case conveyor chains find applications in various industries and scenarios. Some common usage scenarios include:

- Material Handling: Our sprockets are widely used in conveyor systems for transporting heavy loads, such as in manufacturing plants and warehouses.

- Automotive Production: Sprockets play a vital role in automotive assembly lines, ensuring the smooth movement of components throughout the production process.

- Agricultural Machinery: Sprockets are utilized in agricultural equipment, such as harvesters and tractors, assisting in the efficient operation of these machines.

Historial y clasificación del producto

Sprockets have a rich history dating back to the early days of industrialization. Over the years, they have evolved and diversified to meet the demands of various industries. In terms of classification, sprockets can be categorized based on their tooth profile, pitch diameter, bore size, and number of teeth.

Ventajas de nuestras ruedas dentadas

- Durability: Our sprockets are crafted from high-quality materials to ensure long-lasting performance even in harsh operating conditions.

- Precision Engineering: Each sprocket is meticulously designed and manufactured to maintain optimal chain engagement, minimizing wear and tear.

- Easy Installation: Our sprockets feature user-friendly designs, making installation quick and hassle-free.

- Low Maintenance: With proper maintenance, our sprockets require minimal upkeep, reducing downtime and overall operating costs.

Materiales de producto disponibles

We offer sprockets in various materials to suit different application requirements. Some common materials include:

- Stainless Steel: Ideal for applications where corrosion resistance is crucial.

- Carbon Steel: Provides excellent strength and durability.

- Plastic: Offers lightweight and cost-effective solutions for less demanding applications.

Instalación, mantenimiento y reparación

Installing, maintaining, and repairing our sprockets is a straightforward process. Here are some key steps to follow:

- Instalación:

- Ensure the sprocket matches the chain specifications.

- Align the sprocket with the chain and secure it in place using appropriate fasteners.

- Check for proper tension and adjust if necessary.

- Mantenimiento:

- Regularly inspect the sprocket for signs of wear or damage.

- Keep the sprocket clean and free from debris.

- Lubricate the sprocket periodically to reduce friction and improve performance.

- Reparar:

- If any teeth on the sprocket are damaged, they should be replaced immediately to prevent further issues.

- Follow the manufacturer's instructions or consult a professional for proper repair procedures.

Otros negocios de productos de la empresa

Aside from sprockets for forged case conveyor chains, [Company Name] specializes in supplying various industrial plastic gears and components. Our extensive product range includes:

- Cajas de cambios agrícolas

- Ejes de salida de potencia

- Acoplamientos hidráulicos

- Reductores de engranajes helicoidales

- Cremalleras

- Cadenas extraíbles

- Poleas y poleas

- Cajas de engranajes planetarios

- Poleas de distribución

- Bujes

We pride ourselves on offering high-quality products at competitive prices, accompanied by exceptional customer service. We welcome customization requests and are capable of delivering products that meet your specific requirements. Feel free to reach out to us with any inquiries or to request samples.

5 Questions and Answers:

1. Q: What industries commonly use sprockets for forged case conveyor chains?

A: Sprockets for forged case conveyor chains find applications in industries such as manufacturing, automotive, and agriculture.

2. Q: What are the advantages of using stainless steel sprockets?

A: Stainless steel sprockets offer excellent corrosion resistance, making them ideal for environments where moisture or chemicals are present.

3. Q: How often should sprockets be lubricated?

A: Sprockets should be lubricated periodically, typically following the manufacturer's recommendations or based on the operating conditions.

4. Q: Can damaged sprocket teeth be repaired?

A: In most cases, damaged sprocket teeth should be replaced rather than repaired to ensure optimal performance and reliability.

5. Q: Can [Company Name] provide customized sprockets?

A: Yes, [Company Name] offers customization services to meet specific requirements. Please contact us to discuss your needs.

Autor: lmc

Disclaimer: All content on this page is sourced from the internet and is intended for reference purposes only. Our products are aftermarket accessories and not original spare parts. We do not hold the original trademark of the content. While our accessories can perfectly fit original spare parts, if you require original spare parts, please contact the original manufacturer for purchase.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios