El conjunto del eje de transmisión fijo (FB)

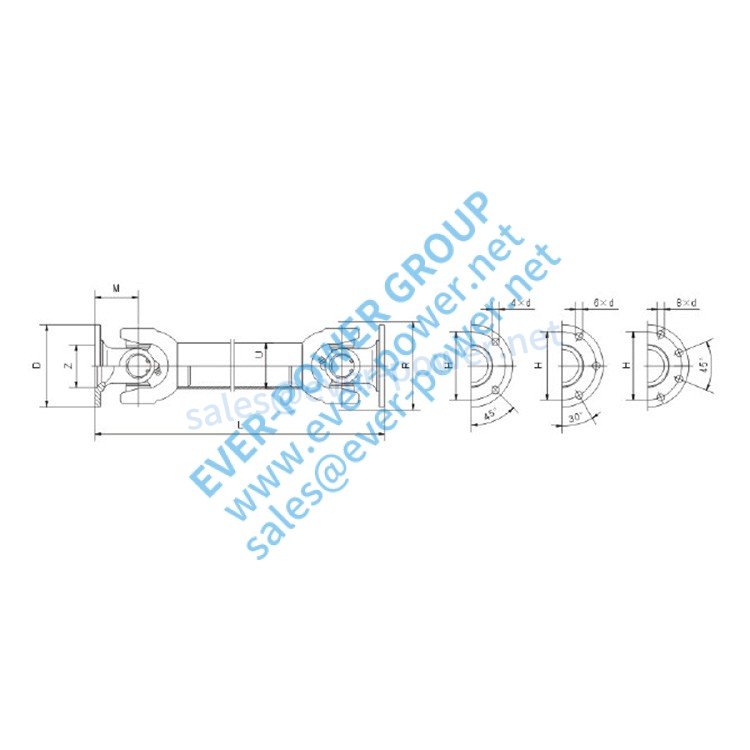

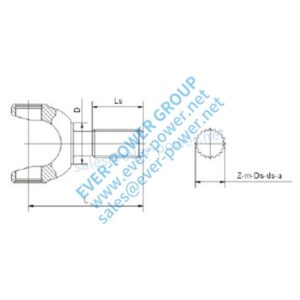

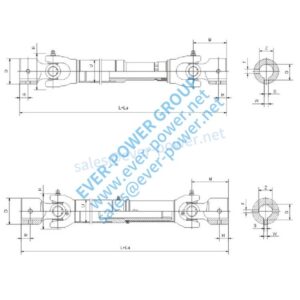

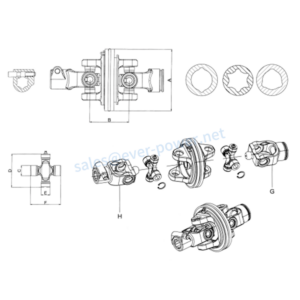

The Fixed Transmission Shaft Assembly (FB)

The fixed transmission shaft assembly (FB) is an essential component in various industrial applications. With its sturdy construction and reliable performance, it plays a crucial role in transmitting power and torque from the engine to other mechanical parts.

Escenarios de uso común

- Automotive Industry: The FB assembly is widely used in automobiles for transmitting power from the engine to the wheels, ensuring smooth and efficient movement.

- Machinery and Equipment: It is commonly utilized in heavy machinery and equipment, such as construction machinery, agricultural machinery, and industrial machinery.

- Power Generation: The FB assembly is essential in power plants, where it transfers power from turbines to generators for electricity production.

Historia del producto, clasificación y ventajas

The fixed transmission shaft assembly (FB) has a long history, evolving alongside advancements in mechanical engineering. It is classified into various types based on its design, size, and application requirements.

Advantages of the FB assembly include:

- High Efficiency: The precise engineering of the assembly ensures minimal power loss during transmission.

- Durability: Constructed with high-quality materials, it can withstand heavy loads and harsh operating conditions.

- Smooth Operation: The assembly's design minimizes vibrations and noise, providing a smooth and quiet transmission process.

Materiales e instalación

The FB assembly can be manufactured using different materials, including steel alloys, stainless steel, and carbon fiber. The choice of material depends on factors such as load capacity, durability requirements, and industry-specific needs.

Installation of the FB assembly involves precise alignment and secure fastening to ensure optimal performance. It is crucial to follow manufacturer guidelines and use suitable tools during the installation process.

Mantenimiento, reparación y reemplazo

To maintain the longevity and reliability of the FB assembly, regular maintenance is recommended. This includes periodic lubrication, inspection of component wear, and addressing any signs of damage or malfunction promptly.

In case of repair, it is advised to consult a professional or follow manufacturer guidelines for disassembly, replacement of faulty components, and reassembly.

When the FB assembly reaches the end of its service life or requires upgrading, replacement is necessary. It is essential to source genuine parts from reputable suppliers to ensure compatibility and optimal performance.

Otros productos y negocios

Aside from the fixed transmission shaft assembly (FB), our company specializes in supplying a wide range of high-quality industrial components. Some of our notable products include:

- Plastic Gear: We offer a variety of plastic gears suitable for different industrial applications, such as agricultural gearboxes, power output shafts, and sprockets.

- Fluid Couplings: Our fluid couplings provide efficient torque transmission and are widely used in machinery and equipment.

- Worm Gear Reducers: These reducers offer precise and reliable speed reduction for various machinery and systems.

- Gears and Racks: We supply a comprehensive range of gears and racks for smooth and accurate motion control.

- Planetary Gearboxes: Our planetary gearboxes are known for their compact design, high torque capacity, and precise operation.

We also offer timing pulleys, bushings, detachable chains, pulleys, and more. Our products are characterized by their high quality, competitive prices, and dedicated customer service. We welcome customers to contact us for customized solutions based on their specific requirements.

Q&A (based on the content of the article)

1. What is the primary function of the fixed transmission shaft assembly (FB)?

The primary function of the FB assembly is to transmit power and torque from the engine to other mechanical parts.

2. In which industries is the FB assembly commonly used?

The FB assembly is commonly used in the automotive industry, machinery and equipment, and power generation.

3. What are the advantages of the FB assembly?

The advantages of the FB assembly include high efficiency, durability, and smooth operation.

4. What materials are used in manufacturing the FB assembly?

The FB assembly can be manufactured using materials such as steel alloys, stainless steel, and carbon fiber.

5. What are some other products offered by the company?

Some other products offered by the company include plastic gears, fluid couplings, worm gear reducers, gears and racks, and planetary gearboxes.

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios