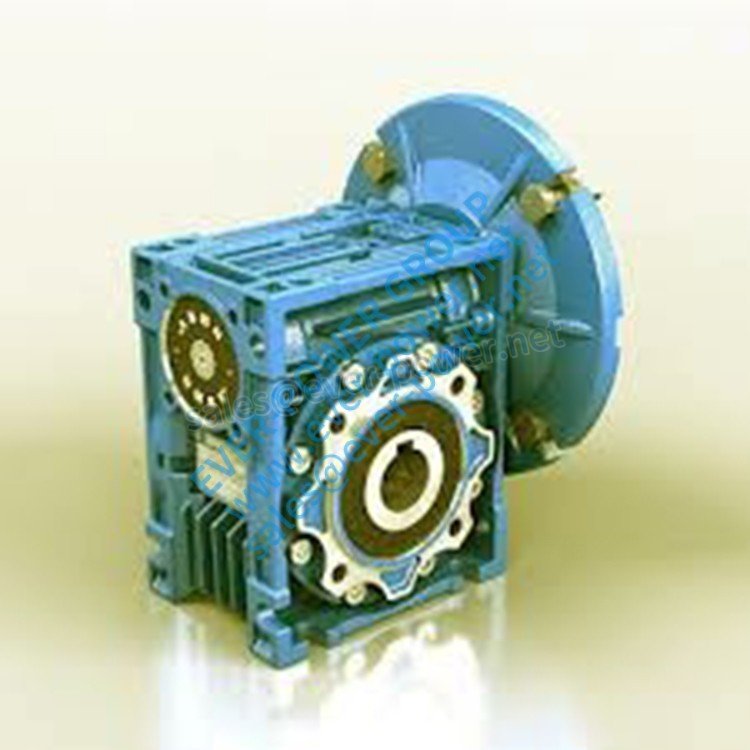

unidad de engranaje helicoidal

Reductor de tornillo sin fin: solución de transmisión de potencia eficiente y de alta calidad

Los reductores de tornillo sin fin se utilizan ampliamente en diversas aplicaciones industriales gracias a su eficiencia, tamaño compacto y excelente capacidad de carga. HZPT es una marca de confianza en la industria, ofreciendo reductores de tornillo sin fin de alta calidad que ofrecen un rendimiento excepcional incluso en condiciones extremas.

La historia de los engranajes helicoidales:

Los engranajes sinfín se han utilizado durante siglos y se cree que su origen se remonta a la antigua Grecia y Egipto. Desde entonces, se han empleado en diversas aplicaciones, desde molinos de viento hasta maquinaria pesada. Hoy en día, se emplean en casi todas las industrias que requieren un alto par y un control de movimiento preciso.

Clasificación y ventajas de los reductores helicoidales:

Los reductores de tornillo sin fin se clasifican según el número de roscas del sinfín y la orientación de su eje. Los tipos más comunes son los de rosca simple y doble, con orientación derecha o izquierda. Los reductores de tornillo sin fin ofrecen varias ventajas, entre ellas:

- Alta capacidad de carga

- Transmisión de potencia eficiente

- Funcionamiento silencioso

- Tamaño compacto

- Fácil instalación y mantenimiento

Materiales utilizados en unidades de engranajes helicoidales:

HZPT concede gran importancia a la calidad de los materiales utilizados en los reductores de sinfín para garantizar una larga vida útil y un alto rendimiento. Las piezas de la carcasa están fabricadas en fundición gris de alta calidad (EN-GJL-200), mientras que los casquillos huecos, a partir de reductores de tamaño superior a 100, están fabricados en fundición de grafito esferoidal (EN-GJS-400-15). Los ejes de los reductores de sinfín están fabricados en 16MnCrS5BG, templado y rectificado para una mayor resistencia al desgaste. Las llantas de los reductores de sinfín son de bronce macizo fundido por centrifugación con aditivos de níquel GzCuSn12Ni, lo que proporciona unas excepcionales propiedades de suavidad y funcionamiento en situaciones de emergencia.

Instalación, mantenimiento y reparación:

La instalación, el mantenimiento y la reparación adecuados de los reductores sinfín son cruciales para garantizar su óptimo rendimiento y una larga vida útil. Durante la instalación, asegúrese de que la alineación del eje sea correcta y la lubricación sea adecuada. El mantenimiento rutinario incluye la comprobación de fugas, la lubricación adecuada y el desgaste de engranajes y cojinetes. En caso de reparación, se recomienda sustituir los componentes desgastados lo antes posible para evitar mayores daños a la unidad.

Otros productos ofrecidos por HZPT:

Además de reductores sinfín, HZPT también suministra diversos engranajes de plástico para la industria, como cajas de engranajes agrícolas, ejes de salida de potencia, ruedas dentadas, acoplamientos hidráulicos, engranajes y cremalleras, cadenas desmontables, poleas, reductores planetarios, poleas de distribución, bujes y más. Nos comprometemos a ofrecer productos de alta calidad, precios competitivos y un servicio atento a nuestros clientes. Les invitamos a contactarnos con sus planos o muestras para personalizarlos.

Preguntas y respuestas:

- ¿Cuáles son las ventajas de utilizar un engranaje helicoidal en aplicaciones industriales?

- ¿Cuáles son los diferentes tipos de reductores de tornillo sin fin disponibles?

- ¿Qué materiales se utilizan en los reductores de tornillo sin fin de HZPT?

- ¿Cuál es el procedimiento de mantenimiento recomendado para las unidades de engranajes sin fin?

- ¿Qué otros productos suministra HZPT además de reductores de tornillo sin fin?

Sobre nosotros

¡Garantizamos productos de primera calidad a los mejores precios en China! Aceptamos pedidos especiales y, si está interesado en alguno de nuestros productos, no dude en comunicarse con nosotros para obtener información más detallada. Nos aseguramos de que nuestros productos sean seguros, de alta calidad y a un precio razonable. Comuníquese con nosotros lo antes posible si desea obtener más información. Estamos ansiosos por cooperar contigo!

Una gran parte de nuestros productos se exporta a Europa y América, con opciones estándar y personalizadas disponibles. Podemos fabricar según sus dibujos o muestras, utilizando materiales estándar o según sus requisitos específicos. Elegirnos significa elegir confiabilidad.

Materiales disponibles

1. Acero inoxidable: SS201, SS303, SS304, SS316, SS416, SS420

2. Acero: C45 (K1045), C46 (K1046), C20

3. Latón: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronce: C51000, C52100, C54400, etc.

5. Hierro: 1213, 12L14,1215

6. Aluminio: Al6061, Al6063

7.OEM según su solicitud

Tratamiento de superficies

Recocido, canonización natural, tratamiento térmico, pulido, niquelado, cromado, galvanizado, pasivación amarilla, pasivación dorada, satinado, pintura superficial negra, etc.

Método de procesamiento

Mecanizado CNC, punzonado, torneado, fresado, taladrado, rectificado, brochado, soldadura y montaje.

Control de calidad y certificado

Los técnicos realizan autocontrol en la producción, control final antes del paquete por parte de un inspector de calidad profesional.

ISO9001:2008, ISO14001:2001, ISO/TS 16949:2009

Paquete y plazo de entrega

Tamaño: Dibujos

Caja/contenedor de madera y paleta, o según especificaciones personalizadas.

Muestras de 15 a 25 días. Pedido oficial de 30 a 45 días.

Puerto: Puerto de Shanghái/Ningbo

Industrias a las que prestamos servicios