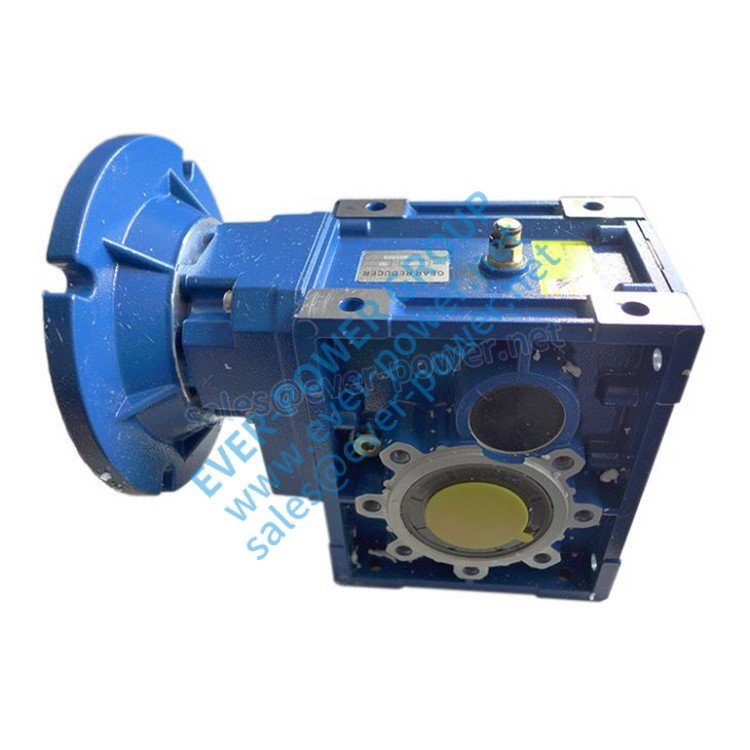

engrenagem helicoidal sem-fim

Helical Worm Gear: Performance Characteristics and Application

The helical worm gear is a versatile and efficient mechanical component widely used in various industries. With its systematic and modular design, this gear offers a fine stage transmission ratio that covers a wide range of applications. Its high efficiency and low energy consumption make it a superior choice for power transmission. Let's explore the performance characteristics and common use scenarios of the helical worm gear.

Performance Characteristics:

- Systematic and modular design for versatile applications

- High precision gear with teeth grinding for stable transmission

- Low noise and strong bearing capacity for smooth operation

- Compact design with small volume and simple installation

- Suitable for all kinds of mounting positions

The helical worm gear is known for its excellent performance and reliability. Its fine-stage transmission ratio allows it to adapt to a wide range of applications, making it suitable for various industrial needs. This gear's high precision, achieved through teeth grinding, ensures a stable and efficient transmission, while its low noise operation ensures a peaceful working environment. Additionally, its compact design and easy installation make it a popular choice across different industries.

Material:

The helical worm gear is manufactured using high-quality materials to ensure durability and longevity. The main components of this gear are:

- Habitação: Made of high strength cast iron HT250, the housing is designed to reduce abrasion and provide robust support.

- Engrenagens: Constructed with 20CrMo and carbonitriding process, the gears achieve a teeth hardness of HRC 60 after grinding, ensuring excellent wear resistance.

- Flat keys: Utilizing C45 with a surface hardness of HRC 50, the flat keys provide secure and reliable connections.

The use of high-quality materials in the manufacturing process ensures the helical worm gear's longevity and reliability. The housing, made of high strength cast iron, provides excellent support and reduces the risk of wear. The gears, manufactured with precision using 20CrMo and subjected to carbonitriding, offer exceptional hardness and wear resistance. Additionally, the flat keys used in the gear guarantee secure and reliable connections.

Instalação, manutenção e reparo:

Installing, maintaining, and repairing the helical worm gear is relatively straightforward. However, it is essential to follow the manufacturer's guidelines and recommendations to ensure optimal performance and longevity. Here are some key points to consider:

- Instalação: Prior to installation, ensure that all components are clean and free from any damage. Pay attention to proper alignment and lubrication.

- Manutenção: Regularly inspect the gear for any signs of wear or damage. Keep the gear properly lubricated as per the manufacturer's specifications.

- Reparar: In case of damage or malfunction, consult a professional technician or the manufacturer for appropriate repair procedures.

- Substituição: When replacing the helical worm gear, choose a suitable replacement based on the required specifications and consult the manufacturer if needed.

By following these installation, maintenance, and repair guidelines, you can ensure that your helical worm gear operates smoothly and efficiently for an extended period.

Outros produtos de qualidade oferecidos por nossa empresa

In addition to the helical worm gear, our company specializes in supplying various plastic gears used in the industrial sector. Our extensive range of products includes:

- Caixas de engrenagens agrícolas

- Eixos de saída de potência

- Rodas dentadas

- Acoplamentos de fluidos

- Redutores de engrenagem sem-fim

- Engrenagens e cremalheiras

- Correntes destacáveis

- Polias e roldanas

- Caixas de engrenagens planetárias

- Polias de sincronização

- Buchas

We take pride in offering high-quality products at competitive prices. Our commitment to providing excellent service and customer satisfaction sets us apart. We welcome customers to approach us for customizations based on their specific requirements, whether it is a drawing or a sample. Experience our superior products, favorable pricing, and attentive service today!

Perguntas e respostas:

Q1: What industries can benefit from using helical worm gears?

A1: Helical worm gears find applications in various industries such as automotive, food processing, packaging, and material handling. Their versatility and efficiency make them suitable for a wide range of power transmission needs.

Q2: Can the helical worm gear withstand heavy loads?

A2: Yes, the helical worm gear is designed to have a strong bearing capacity, allowing it to handle heavy loads effectively. It offers reliable performance even under demanding conditions.

Q3: Are there any specific lubrication requirements for the helical worm gear?

A3: Proper lubrication is crucial for optimal performance and longevity. Consult the manufacturer's guidelines to determine the suitable lubricant type and frequency of lubrication for your specific application.

Q4: Can the helical worm gear be repaired if it gets damaged?

A4: Yes, in case of damage or malfunction, the helical worm gear can often be repaired. Consult a professional technician or contact the manufacturer for guidance on the appropriate repair procedures.

Q5: How can I request a custom product from your company?

A5: To request a custom product, simply provide us with your specific requirements, such as the desired dimensions, material specifications, and any other relevant details. Our team will work closely with you to deliver a tailored solution.

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos