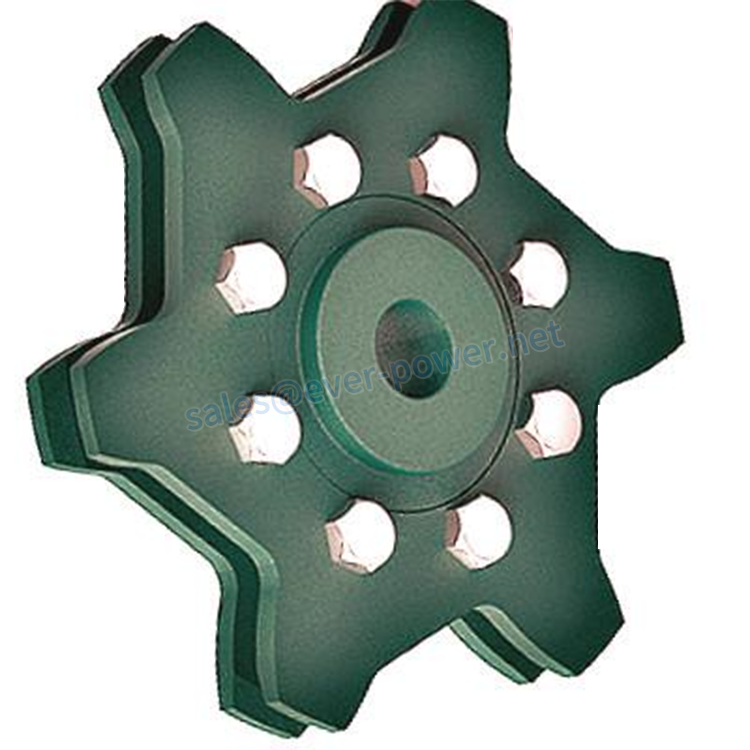

Roda dentada da corrente do raspador

Aplicações e vantagens das rodas dentadas de corrente raspadora

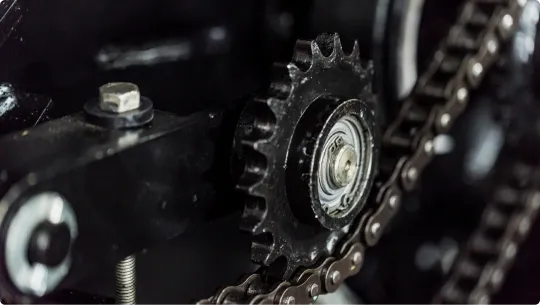

Rodas dentadas para correntes raspadoras são um componente essencial utilizado em diversas aplicações industriais. São utilizadas em sistemas transportadores, elevadores e outros equipamentos pesados para transferir potência ou movimento entre dois eixos paralelos. Essas rodas dentadas são utilizadas principalmente em aplicações onde cargas pesadas precisam ser transferidas com suavidade e precisão.

Estas rodas dentadas são construídas com matéria-prima de alta qualidade, sob a supervisão criteriosa de nossa equipe especializada, em conformidade com os parâmetros estabelecidos pela indústria. São fabricadas com matéria-prima de alta qualidade para garantir sua ausência de erros. Estas rodas dentadas são robustas e têm acabamento liso, o que garante uma vida útil mais longa com manutenção mínima.

História e classificação das rodas dentadas de corrente raspadora

A história das rodas dentadas remonta ao início dos anos 1900, quando a Revolução Industrial estava em pleno andamento. As rodas dentadas foram inventadas em função da necessidade de uma transmissão de potência mais precisa e suave. Desde então, passaram por inúmeras mudanças e avanços para atender às crescentes demandas de diversos setores.

As rodas dentadas de corrente raspadora são classificadas em vários tipos com base em seu design, passo e material utilizado. Os tipos mais utilizados são rodas dentadas simplex, duplex e triplex. Elas também são classificadas com base no número de dentes, diâmetro interno e diâmetro do passo.

Vantagens das rodas dentadas da corrente do raspador

As rodas dentadas de corrente raspadora têm inúmeras vantagens, como:

- Alta capacidade de carga

- Transmissão de potência precisa e suave

- Longa vida útil com baixa manutenção

- Resistência à corrosão e ao desgaste

- Sem escorregar durante a operação

Materiais disponíveis e instalação

As rodas dentadas da corrente raspadora são fabricadas com diferentes tipos de materiais, como aço, ferro fundido e plástico. O material utilizado depende da aplicação e da capacidade de carga necessária.

A instalação dessas rodas dentadas é relativamente simples e pode ser feita com ferramentas básicas. É essencial mantê-las limpas e livres de detritos, pois qualquer acúmulo pode causar mau funcionamento.

Manutenção e Reparo

A manutenção adequada das rodas dentadas da corrente do raspador é crucial para garantir sua longevidade e bom funcionamento. Limpeza e lubrificação regulares devem ser realizadas para evitar desgaste ou corrosão. Em caso de danos ou mau funcionamento, recomenda-se a substituição imediata da roda dentada para evitar maiores danos ao equipamento.

Outros produtos oferecidos pela nossa empresa

Em nossa empresa, oferecemos uma ampla gama de engrenagens plásticas industriais, como caixas de engrenagens agrícolas, eixos de saída de potência, acoplamentos hidráulicos, redutores de engrenagem helicoidal, cremalheiras, correntes removíveis, polias e polias, caixas de engrenagens planetárias, polias sincronizadoras e buchas. Nossos produtos são de alta qualidade e oferecemos preços competitivos para atender às necessidades de nossos clientes. Convidamos nossos clientes a personalizar seus produtos com fotos e amostras.

Perguntas Frequentes (FAQs)

P1. O que são rodas dentadas de corrente raspadora?

Rodas dentadas de corrente raspadora são um componente essencial utilizado em diversas aplicações industriais. São utilizadas principalmente em sistemas transportadores, elevadores e outros equipamentos pesados para transferir potência ou movimento entre dois eixos paralelos.

Q2. Quais são as vantagens de usar rodas dentadas de corrente raspadora?

As rodas dentadas de corrente raspadora têm inúmeras vantagens, como alta capacidade de carga, precisão e transmissão de potência suave, longa vida útil com baixa manutenção, resistência à corrosão e ao desgaste e ausência de deslizamento durante a operação.

Q3. Quais materiais são usados para fabricar as rodas dentadas da corrente do raspador?

As rodas dentadas da corrente raspadora são fabricadas com diferentes tipos de materiais, como aço, ferro fundido e plástico. O material utilizado depende da aplicação e da capacidade de carga necessária.

Q4. Como deve ser feita a manutenção das rodas dentadas da corrente do raspador?

A manutenção adequada das rodas dentadas da corrente do raspador é crucial para garantir sua longevidade e bom funcionamento. Limpeza e lubrificação regulares devem ser realizadas para evitar desgaste ou corrosão.

Q5. Quais outros produtos são oferecidos pela sua empresa?

Em nossa empresa, oferecemos uma ampla gama de engrenagens plásticas industriais, como caixas de engrenagens agrícolas, eixos de saída de potência, acoplamentos hidráulicos, redutores de engrenagem helicoidal, cremalheiras, correntes removíveis, polias e polias, caixas de engrenagens planetárias, polias sincronizadoras e buchas.

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos