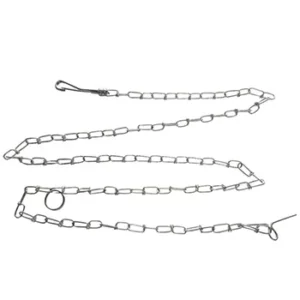

EPG43 NACM90 Link Chain

Stainless Steel Link Chain: A Versatile and Durable Option

Stainless steel link chain is a widely used industrial product due to its versatility, strength, and durability. It is commonly used in a variety of applications, including marine, construction, and mining industries. The product is made up of multiple links that are connected together to form a chain. These links can be thin or heavy, depending on the intended use of the chain.

A Brief History of Link Chains

Link chains have been around for centuries and were originally made of wrought iron. Over time, the design of link chains has evolved, and they are now made of various materials, including stainless steel. The evolution of link chains has helped improve their strength and durability, making them more useful across a broad range of applications.

Classification of Link Chains

Link chains are classified based on the type of material used to make them. Stainless steel link chains are often preferred due to their rust-resistant properties and ability to withstand harsh environments. They are also available in different grades, including 304 and 316. A grade 316 stainless steel link chain is a good choice for marine applications due to its excellent corrosion resistance.

Advantages of Stainless Steel Link Chains

Stainless steel link chains offer several advantages over other materials. They are highly resistant to corrosion, making them ideal for use in harsh environments. They are also strong and durable, making them suitable for heavy-duty applications. Additionally, stainless steel link chains are easy to clean and maintain, ensuring their longevity.

Cenários de uso

Stainless steel link chains are commonly used for lifting and rigging operations, securing cargo, and hoisting equipment. They are also used in marine applications due to their corrosion-resistant properties. The product is highly versatile and can be used in various other applications, such as mining, construction, and aerospace industries.

Materiais de produtos disponíveis

Stainless steel link chains are available in different grades, including 304 and 316. Grade 316 stainless steel link chains are preferred for their excellent corrosion resistance and are often used in marine applications.

How to Install, Maintain, and Repair Stainless Steel Link Chains

When installing stainless steel link chains, it is essential to ensure that the load is evenly distributed across each link. Chains should be inspected regularly for signs of wear and tear, and any damaged links should be repaired or replaced immediately. Proper maintenance and lubrication of the chain can help prolong its life and prevent damage.

How to Replace Stainless Steel Link Chains

When replacing stainless steel link chains, it is important to select a chain that meets the required specifications for the application. The replacement chain should be of the same size and grade as the original chain to ensure proper performance.

Outros produtos industriais

Our company specializes in various industrial plastic gears, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We pride ourselves on offering high-quality products at competitive prices and providing excellent customer service. We welcome customers to contact us for customizations and are happy to work with pictures and samples.

Q & A

Q: What are link chains used for?

A: Link chains are used for lifting and rigging operations, securing cargo, and hoisting equipment.

Q: What are the advantages of stainless steel link chains?

A: Stainless steel link chains are highly resistant to corrosion, strong and durable, and easy to clean and maintain.

Q: How do I install stainless steel link chains?

A: When installing stainless steel link chains, it is essential to ensure that the load is evenly distributed across each link.

Q: What should I do if my stainless steel link chain is damaged?

A: Any damaged links on a stainless steel link chain should be repaired or replaced immediately to prevent further damage.

Q: What other industrial products does your company offer?

A: Our company specializes in various industrial plastic gears, including agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, and more.

Disclaimer: All content on this page is for reference only and should not be considered as original spare parts. Our products are accessories and not original spare parts; we are not the holder of the original trademark of the content. Our accessories can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory to purchase.

Autor: lmc

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

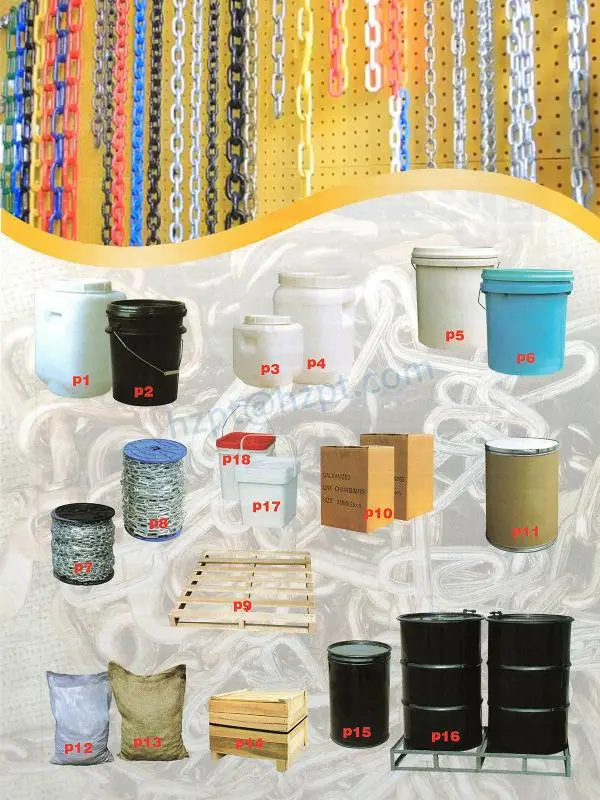

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos