Caixas de engrenagens de cortadores de mangual – Substituição do Comer Code T-292B 1.86:1

A Caixa de Engrenagens T-292B para Cortadores de Grama, fabricada pela TEBSA na Argentina, é um componente essencial para cortadores de grama, projetada para lidar com tarefas exigentes como cortar grama, arbustos e vegetação densa. Desde 1997, a TEBSA é uma marca confiável em máquinas agrícolas, oferecendo uma garantia de qualidade de 100% e uma vantagem de custo de 50% em relação às marcas originais. Esta caixa de engrenagens de velocidade única aciona cortadores de grama com larguras de corte de até 1,6 metro, proporcionando desempenho confiável para as fazendas argentinas, das planícies dos Pampas aos campos de Córdoba.

Construído para durar, o T-292B oferece até 60 cavalos de potência e um torque máximo de 542 Nm, tornando-o ideal para tarefas agrícolas e paisagísticas pesadas. Suas engrenagens e rolamentos de alta qualidade suportam o estresse do corte de vegetação densa, enquanto um sistema de lubrificação por banho de óleo mantém os componentes resfriados e reduz o desgaste, garantindo uma longa vida útil. Com a engenharia especializada da TEBSA e a equipe de resposta 24 horas, esta caixa de engrenagens é uma escolha inteligente para agricultores e paisagistas que buscam eficiência e valor.

Especificações técnicas e características de design

A caixa de engrenagens do cortador de grama T-292B foi projetada para oferecer precisão e robustez, adaptada para atender às necessidades do setor agrícola argentino. Sua carcaça de ferro fundido GGG40 oferece resistência excepcional, resistindo a impactos e vibrações em ambientes agressivos, como plantações de soja ou trigo. A relação de transmissão de 1,86:1 da caixa de engrenagens otimiza a transferência de potência do Eixo de tomada de força às lâminas do mangual, garantindo uma operação suave em velocidades variadas.

Os principais detalhes técnicos incluem:

Capacidade de potência: até 58,9 kW (80 HP), adequado para cortadores de grama de médio porte.

Saída de torque: 54,2 daNm (542 Nm), capaz de lidar com vegetação densa.

Sistema de óleo: requer 2,5 litros de óleo 80W-90, com troca de óleo recomendada inicialmente após 50-70 horas e depois a cada 500-700 horas ou anualmente.

Peso: 33 kg, equilibrando durabilidade com facilidade de instalação.

As engrenagens do T-292B, fabricadas em aço-liga por meio de forjamento avançado e tratamento térmico (carbonitretação), oferecem excelente resistência ao desgaste. Seus rolamentos cônicos garantem rotação suave sob cargas pesadas, enquanto o sistema de banho de óleo mantém a lubrificação ideal, reduzindo os custos de manutenção. Esta caixa de engrenagens é uma substituição direta do Comer Code T-292B, oferecendo compatibilidade perfeita para agricultores argentinos que desejam atualizar seus equipamentos.

| Descrição do produto |

Caixas de engrenagens de cortadores de mangual - Substituição do Comer Code T-292B 1.86:1

|

|---|---|

| Detalhes do produto |

|

| Faixa de aplicação |

|

| Consiste em |

|

| Contém óleo |

Não

|

| Capacidade máx. de óleo |

2,5 l

|

| Intervalo máximo de troca de óleo |

500 horas

|

| Grau de viscosidade SAE do óleo |

80W-90

|

| Material da carcaça |

Ferro fundido GGG40

|

| Peso |

33 kg

|

| Arranjo de engrenagens Aumentando |

33 - 34

|

| Potência de entrada kW / HP Crescente |

58,9 / 80 kW/HP

|

| Eixo de entrada aumentando |

Z

|

| Torque de saída DaNm aumentando |

54,2 daNm

|

| Proporção crescente |

1: 1.86

|

| Redução de Proporção |

1.86: 1

|

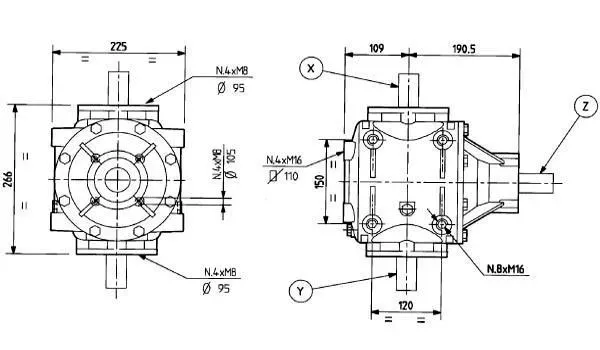

| Eixo X |

35h7

|

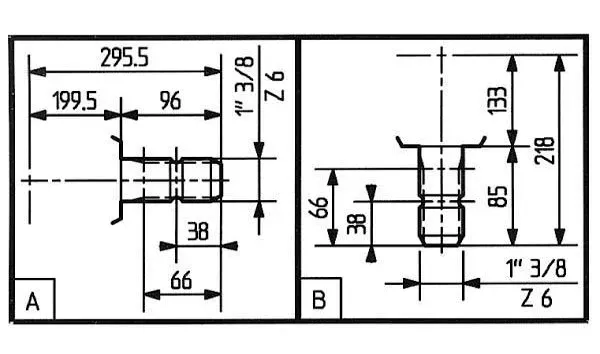

| Eixo Z |

1 3/8" (6) (A)

|

Aplicações e Benefícios na Agricultura Argentina

A caixa de engrenagens do cortador de grama T-292B se destaca em uma variedade de tarefas agrícolas e paisagísticas, tornando-se a escolha ideal para agricultores e empreiteiros argentinos. Ela aciona cortadores de grama usados para limpar grama, ervas daninhas e pequenos arbustos, bem como para cuidar de pastagens, pomares e vegetação à beira de estradas. Sua versatilidade se estende a escarificadores rotativos, ampliando sua utilidade no preparo do solo para culturas como soja, milho e trigo — produtos básicos da economia agrícola argentina.

Em regiões como Buenos Aires ou Santa Fé, onde vegetação densa e terrenos irregulares são comuns, o design robusto do T-292B se destaca. Sua relação de transmissão de 1,86:1 garante uma entrega de potência eficiente, permitindo que os cortadores de grama cortem materiais difíceis sem atolar. A capacidade da caixa de engrenagens de lidar com larguras de corte de até 1,6 metro a torna adequada para fazendas de médio porte e projetos de paisagismo municipal.

Os principais benefícios incluem:

Durabilidade: A carcaça de ferro fundido e as engrenagens de aço-liga, tratadas com cementação, suportam os rigores dos diversos climas da Argentina, desde os pampas úmidos até as terras altas secas.

Eficiência: O sistema de lubrificação por banho de óleo minimiza o atrito, aumentando o desempenho do cortador e reduzindo os custos de combustível.

Economia de custos: a vantagem de custo do 50% da TEBSA sobre marcas originais como a Comer torna o T-292B uma atualização acessível.

Segurança: Uma transferência de potência estável reduz a tensão do equipamento, aumentando a segurança do operador nas fazendas.

Baixa manutenção: trocas de óleo simples e peças acessíveis reduzem o tempo de inatividade, com o suporte 24 horas da TEBSA.

A compatibilidade do T-292B com eixos de tomada de força padrão (1 3/8" e 6 estrias) garante fácil integração com tratores comumente usados na Argentina. Para agricultores que administram plantações de soja ou cuidam de vinhedos em Mendoza, esta caixa de engrenagens oferece desempenho confiável safra após safra.

| Aplicativo | Caso de uso na Argentina |

|---|---|

| Manutenção de pastagens | Corte de grama e ervas daninhas em áreas de pastagem de gado, por exemplo, planícies dos Pampas. |

| Limpeza de pomar | Corte da vegetação ao redor de árvores frutíferas em vinhedos de Mendoza. |

| Paisagismo à beira da estrada | Manutenção de acostamentos de rodovias na província de Buenos Aires. |

| Preparação do solo | Suporte a cultivadores rotativos para plantio de trigo ou milho em Santa Fé. |

Dicas de manutenção e instalação para maior durabilidade

Para manter a caixa de engrenagens do cortador de grama T-292B com o melhor desempenho, a manutenção regular é essencial. A TEBSA projeta suas caixas de engrenagens para facilitar a manutenção, garantindo que os agricultores na Argentina possam maximizar o tempo de atividade durante as temporadas de pico. Aqui estão algumas dicas práticas para instalação e cuidados:

Configuração inicial: A caixa de câmbio é enviada sem óleo. Encha-a com 2,5 litros de óleo 80W-90 antes do uso, verificando os níveis corretos pela vareta medidora. Certifique-se de que o eixo da tomada de força (Eixo Z: 1 3/8" 6 estrias) esteja corretamente alinhado para evitar vibrações.

Trocas de óleo: Realize a primeira troca de óleo após 50 a 70 horas de operação e, em seguida, a cada 500 a 700 horas ou anualmente. Use óleo 80W-90 de alta qualidade para manter a lubrificação das engrenagens.

Inspeções: Verifique regularmente se há vazamentos, desgaste nas engrenagens ou ruído nos rolamentos. Resolva os problemas imediatamente para evitar reparos dispendiosos.

Limpeza: Mantenha o eixo de entrada (Eixo X: 35h7) livre de detritos e aplique graxa para evitar corrosão, especialmente em regiões úmidas como Entre Ríos.

Alinhamento: Verifique se a caixa de engrenagens e o cortador estão alinhados corretamente para reduzir o estresse nos rolamentos e engrenagens.

Para os agricultores argentinos, essas etapas são simples e econômicas, especialmente com a equipe de suporte ágil da TEBSA disponível em até 24 horas. O design do T-292B minimiza as necessidades de manutenção, permitindo que você se concentre no trabalho de campo em vez de reparos.

| Tarefa de Manutenção | Freqüência | Ferramentas necessárias |

|---|---|---|

| Verificação do nível de óleo | A cada 50 horas | Vareta medidora de nível, óleo 80W-90 |

| Troca de óleo | 50-70 horas, depois 500-700 horas | Chave inglesa, bandeja de drenagem de óleo |

| Lubrificação de eixos | A cada 100 horas | Pistola de graxa |

| Inspeção de engrenagens/rolamentos | A cada 200 horas | Lanterna, chave inglesa |

Sobre a TEBSA e nossas soluções agrícolas

Desde 1997, a TEBSA é um fabricante líder de caixas de engrenagens agrícolas na Argentina, comprometida em fornecer produtos confiáveis e de alta qualidade com uma vantagem de custo de 50%. Com sede na Argentina, possuímos a certificação ISO9001-2015 e garantimos a qualidade 100% para cada pedido. Nossa talentosa equipe de engenharia responde em até 24 horas, garantindo uma colaboração tranquila para agricultores e empreiteiros em Buenos Aires, Córdoba e outras cidades.

Além da caixa de engrenagens do cortador de grama T-292B, a TEBSA oferece uma ampla gama de caixas de engrenagens agrícolas, incluindo:

Caixas de engrenagens de cortador rotativo: como o RC-61, ideal para cortes pesados.

Caixas de engrenagens para espalhadores de fertilizantes: para distribuição precisa de nutrientes em campos de soja.

Caixas de engrenagens de cultivador rotativo: auxiliam na preparação do solo para trigo e milho.

Caixas de engrenagens para escavadeiras de postes: para cercas e plantio em áreas rurais da Argentina.

Caixas de engrenagens para cortadores de grama: perfeitas para paisagismo municipal e privado.

Também fornecemos eixos de tomada de força e outros componentes, todos fabricados com materiais como aço-liga, aço inoxidável e ferro fundido, utilizando processos avançados como forjamento, cementação e eletroforese. Seja você um vinhedo em Mendoza ou uma fazenda de gado nos Pampas, a TEBSA tem as soluções para aumentar sua produtividade. Entre em contato conosco hoje mesmo para explorar nossa linha completa ou solicitar um orçamento para a caixa de engrenagens do cortador de grama T-292B!

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos