Caixas de engrenagens de máquinas misturadoras de ração – Substituição do código Comer PGA-1602

A Caixa de Engrenagens Misturadora de Ração PGA-1602, fabricada pela TEBSA na Argentina, é uma solução robusta para a mistura de ração animal no setor agrícola. Projetada para misturar grãos, suplementos e outros ingredientes em rações uniformes para gado, esta caixa de engrenagens garante nutrição consistente para bovinos, aves e muito mais. Desde 1997, a TEBSA é um fabricante confiável, oferecendo uma garantia de qualidade 100% e uma vantagem de custo 50% em relação às marcas originais. A PGA-1602 foi projetada para mistura de ração de alto torque e alta resistência, tornando-a uma substituição ideal para as caixas de engrenagens Comer Code PGA-1602.

Esta caixa de engrenagens aciona a câmara de mistura transferindo energia do eixo de entrada com precisão. Sua estrutura robusta, utilizando aço-liga e técnicas avançadas de forjamento, atende às intensas demandas das fazendas pecuárias argentinas, dos Pampas a Córdoba. Com design compacto e rolamento especializado para conexão direta do fuso, simplifica a configuração e aumenta a eficiência. Seja operando com um misturador simples (10 a 14 metros cúbicos) ou um misturador duplo (16 a 24 metros cúbicos), o PGA-1602 oferece desempenho confiável para o preparo de ração.

Principais características e benefícios da caixa de engrenagens do misturador de alimentação PGA-1602

O PGA-1602 se destaca no cenário agrícola argentino por sua durabilidade e eficiência. Veja por que ele é a melhor escolha para mistura de ração:

Alta capacidade de torque: Com um torque máximo de saída de 15.700 Nm (1.570 daNm), ele processa misturas densas de ração, garantindo uma mistura suave mesmo sob cargas pesadas. Isso o torna perfeito para fazendas de grande porte em Buenos Aires ou Santa Fé.

Construção durável: Feita com liga de aço e processada por meio de forjamento e cementação, a caixa de engrenagens resiste ao desgaste em condições difíceis, como os verões úmidos da Argentina ou as planícies empoeiradas.

Instalação simplificada: O rolamento integrado para conexão do fuso roscado elimina a necessidade de kits de rolamentos separados, economizando tempo e reduzindo custos para os agricultores.

Aplicação versátil: Adequado para vagões de mistura de vários tamanhos, ele suporta misturadores simples (10–14 m³) e misturadores duplos (16–24 m³), adaptando-se a diversas operações pecuárias.

Solução econômica: A vantagem de custo do 50% da TEBSA sobre os originais da Comer, aliada à garantia de qualidade 100%, torna o PGA-1602 um investimento inteligente para operadores de máquinas misturadoras de ração.

Fácil manutenção: Projetado para manutenção simples, ele usa óleo 90EP (encomendado separadamente) e vem com peças substituíveis, apoiadas por TEBSAEquipe de resposta 24 horas da 's.

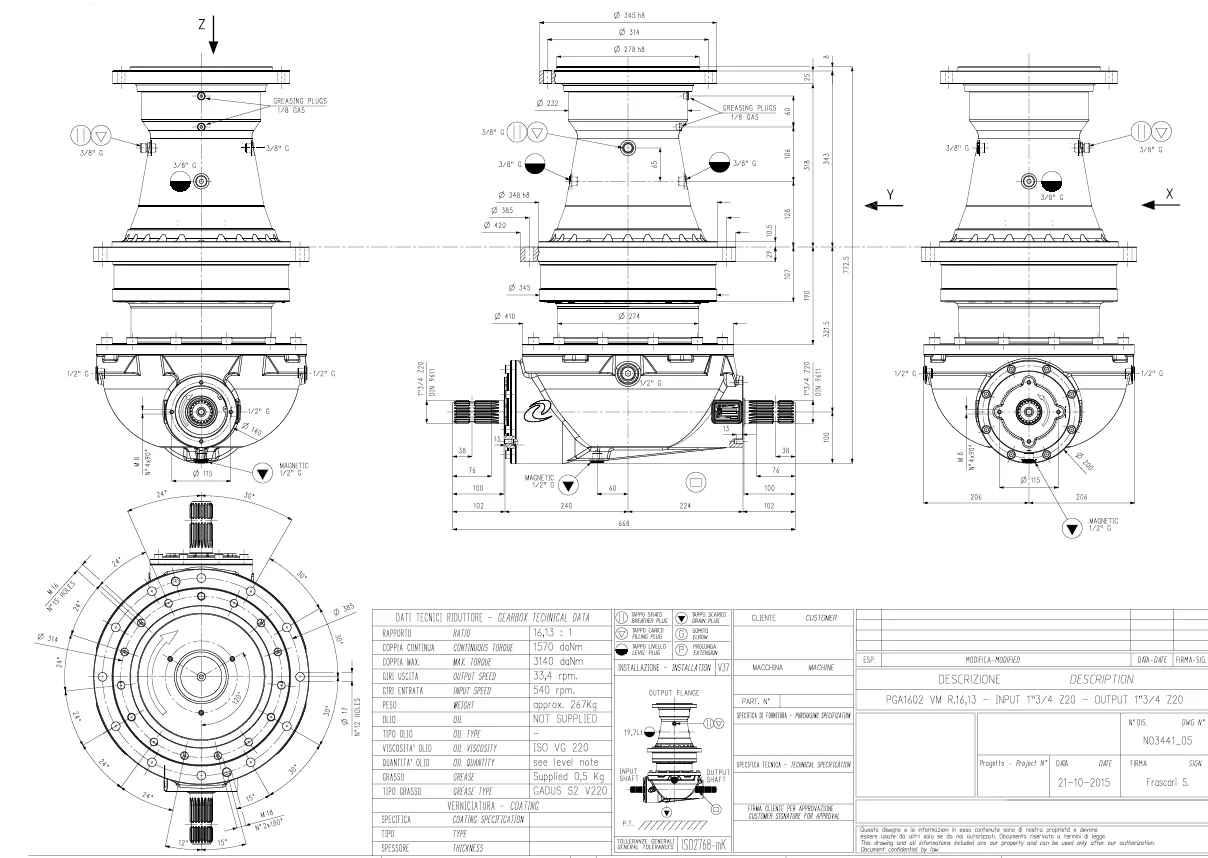

Especificações técnicas da caixa de engrenagens do misturador de alimentação PGA-1602

O PGA-1602 foi projetado para oferecer precisão e potência. Abaixo estão suas especificações detalhadas:

| Descrição |

Caixas de engrenagens para misturadores de alimentação - Substituição para Comer Código PGA-1602

|

|---|---|

| Especificações |

Possui um rolamento especial completo onde o fuso do parafuso pode ser conectado diretamente.

|

| Benefícios |

Nenhum rolamento separado é necessário para o guincho

|

| Aplicativo |

|

| Consiste em |

|

| Modelo |

PGA 1602

|

| Velocidade máxima de rotação de saída |

29 rpm

|

| Torque de saída máx. |

15700 nm

|

| Torque de saída máx. |

1570 daNm

|

| Contém óleo |

Não

|

| Grau de viscosidade SAE do óleo |

90EP

|

| Peso |

265 kg

|

| Relação de transmissão |

16.1:1

|

| Potência de entrada KW / HP Redução |

88,7 kW/HP

|

| Redução de Proporção |

16,2:1

|

| Tipo de eixo |

2 x 1,3/4 (Z20)

|

Dimensões da caixa de engrenagens do misturador de alimentação PGA-1602

Aplicações e Desempenho na Agricultura Argentina

A caixa de engrenagens PGA-1602 é um pilar fundamental na preparação de ração para gado na Argentina, onde a agricultura impulsiona a economia. Ela aciona vagões misturadores que misturam grãos, silagem e suplementos em ração balanceada para gado, vacas leiteiras e aves. Sua capacidade de lidar com alto torque a torna uma escolha confiável para fazendas em regiões como Buenos Aires, Santa Fé e Córdoba, onde as operações pecuárias em larga escala prosperam.

Esta caixa de engrenagens é excelente para vagões misturadores com misturadores simples (10 a 14 metros cúbicos) e duplos (16 a 24 metros cúbicos), atendendo a fazendas de pequeno e grande porte. Por exemplo, ela auxilia fazendas leiteiras que produzem ração para vacas de alta produtividade ou fazendas de corte que preparam rações para gado alimentado a pasto nos Pampas. A relação de transmissão de 16,1:1 e a velocidade de saída de 29 rpm garantem uma mistura completa sem sobrecarregar o sistema, mesmo com ingredientes densos, como silagem úmida ou concentrados proteicos.

O design robusto do PGA-1602, com engrenagens de aço-liga e carburadas, resiste aos variados climas da Argentina — desde verões úmidos até estações secas e poeirentas. Seu tipo de eixo (2 x 1,3/4 Z20) garante uma conexão segura da tomada de força, essencial para a operação contínua durante os períodos de pico de alimentação. Os agricultores podem confiar na engenharia da TEBSA, respaldada pela certificação ISO9001-2015, para manter seus misturadores de ração funcionando sem problemas.

Para destacar sua versatilidade, aqui está uma análise de aplicações típicas:

| Aplicativo | Tamanho do misturador | Caso de uso ideal |

|---|---|---|

| Misturador Único | 10–14 m³ | Pequenas e médias fazendas leiteiras em Córdoba |

| Misturador Duplo | 16–24 m³ | Grandes fazendas de gado bovino nos Pampas |

| Preparação de alimentação personalizada | Varia | Ração especializada para aves em Santa Fé |

Dicas de manutenção e operação para longevidade

Para manter o PGA-1602 com o melhor desempenho, a manutenção regular é fundamental. A TEBSA projeta esta caixa de engrenagens para fácil manutenção, garantindo o mínimo de tempo de inatividade para os agricultores argentinos. Aqui estão algumas dicas práticas:

Verifique os níveis de óleo: Use óleo 90EP (adquirido separadamente) e inspecione os níveis a cada 100 horas de operação. Troque o óleo a cada 1.000 horas ou anualmente para evitar contaminação.

Inspecione quanto a desgaste: procure por vazamentos ou danos na carcaça da caixa de engrenagens, especialmente após uso pesado em condições de poeira, como as do interior da Argentina.

Lubrifique os eixos: mantenha os 2 eixos 1.3/4 Z20 lubrificados para garantir um engate suave da tomada de força e reduzir o atrito.

Monitore o alinhamento: certifique-se de que a caixa de engrenagens e o vagão de mistura estejam alinhados corretamente para evitar tensão nas engrenagens, o que pode levar ao desgaste prematuro.

Limpe regularmente: remova resíduos de alimentação ou detritos do exterior da caixa de engrenagens para evitar corrosão, principalmente em regiões úmidas como Buenos Aires.

A equipe de resposta 24 horas da TEBSA está pronta para ajudar com peças ou dúvidas técnicas, garantindo que seu misturador de ração permaneça operacional. O peso de 265 kg da caixa de engrenagens a torna robusta e fácil de instalar, e a ausência de óleo pré-abastecido permite que os agricultores escolham o melhor lubrificante para suas condições.

Para um desempenho ideal, combine o PGA-1602 com um eixo de tomada de força projetado para misturadores de ração. Os processos de forjamento e tratamento térmico da TEBSA, como a carbonitretação, aumentam a durabilidade das engrenagens, reduzindo os custos de manutenção ao longo do tempo. A potência de entrada de 88,7 kW/HP desta caixa de engrenagens suporta tratores de alto rendimento, comuns nas fazendas modernas da Argentina.

Por que escolher a TEBSA para caixas de engrenagens de misturadores de alimentação na Argentina

Desde 1997, a TEBSA é um fabricante líder de caixas de engrenagens agrícolas na Argentina, oferecendo soluções confiáveis e econômicas para agricultores e operadores industriais. Com sede na Argentina, entendemos as demandas únicas da agricultura local, desde plantações de soja até fazendas de gado. Nossa caixa de engrenagens PGA-1602 reflete nosso compromisso com a qualidade, respaldada pela certificação ISO9001-2015 e pela garantia de qualidade 100% em cada pedido.

Nossa vantagem de custo do 50% em relação a marcas originais como a Comer torna a TEBSA uma escolha inteligente para agricultores com orçamento limitado, sem comprometer o desempenho. Com uma equipe de engenharia qualificada que responde em até 24 horas, garantimos a continuidade do seu equipamento. O PGA-1602, com sua construção em aço-liga e fabricação avançada (forjamento, cementação e retificação), foi projetado para durar nas condições mais adversas da Argentina.

Além das caixas de engrenagens dos misturadores de ração, a TEBSA oferece uma ampla gama de soluções agrícolas:

Caixas de engrenagens de cortadores rotativos: como o RC-61, perfeito para manejo de pastagens.

Caixas de engrenagens para espalhadores de fertilizantes: para aplicação precisa de nutrientes em campos de soja ou trigo.

Caixas de engrenagens para escavadeiras de postes: ideais para cercas em grandes fazendas.

Caixas de engrenagens de enxadas rotativas: Para preparação do solo nas planícies férteis da Argentina.

Eixos de tomada de força: compatíveis com vários implementos agrícolas para transferência de potência perfeita.

Explore nosso catálogo completo em caixas-de-engrenagens-agrícolas.com ou entre em contato conosco para discutir suas necessidades. A TEBSA é sua parceira de confiança para caixas de engrenagens agrícolas na Argentina, oferecendo durabilidade, eficiência e valor desde 1997.

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos