Caixa de engrenagens do misturador de alimentação horizontal - Substituição da caixa de engrenagens Comer D732A 1:1/1.93:1

Caixa de engrenagens do misturador de alimentação horizontal - Substituição da caixa de engrenagens Comer D732A 1:1/1.93:1

A Caixa de Engrenagens do Misturador de Ração Horizontal, projetada como substituição direta do Comer D732A, é um componente vital para as operações de mistura de ração agrícola na Argentina. Projetada pela TEBSA, fabricante confiável desde 1997, esta caixa de engrenagens atende às especificações do original para compatibilidade perfeita e desempenho de ponta. Construída para lidar com a exigente tarefa de misturar ração para o gado, ela garante eficiência e confiabilidade em ambientes agrícolas difíceis, como as planícies dos Pampas. Com garantia de qualidade 100% e vantagem de custo 50% em relação às marcas originais, TEBSA oferece uma solução durável e de alto valor.

Fabricada em ferro fundido GG25, a caixa de engrenagens é resistente ao desgaste, suportando o uso contínuo no processamento de ração. Suas engrenagens e rolamentos usinados com precisão suportam cargas pesadas, enquanto a carcaça reforçada minimiza a necessidade de manutenção. As relações de transmissão personalizadas (1:1 ou 1,93:1) otimizam a mistura para tarefas específicas, aumentando a produtividade dos agricultores argentinos que trabalham com soja, milho ou ração para gado. Esta caixa de engrenagens de substituição mantém sua operação funcionando sem problemas, reduzindo o tempo de inatividade e aumentando a produtividade.

Por que escolher a caixa de engrenagens de substituição TEBSA D732A?

A caixa de engrenagens do misturador de ração horizontal TEBSA se destaca por seu design robusto e benefícios práticos, adaptada às necessidades do setor agrícola argentino. Veja por que é uma escolha inteligente:

Compatibilidade Perfeita: Projetado para substituir o Comer D732A, ele se adapta perfeitamente aos misturadores de ração existentes, garantindo instalação rápida e sem modificações. Isso o torna ideal para agricultores em Buenos Aires ou Córdoba que buscam modernizar o sistema sem complicações.

Alta durabilidade: feito de ferro fundido e com engrenagens tratadas termicamente (por meio de cementação), ele suporta os rigores da mistura diária de ração, desde pequenas fazendas leiteiras até grandes operações de gado.

Desempenho otimizado: com relações de transmissão de 1:1 ou 1,93:1, proporciona transferência de potência precisa, melhorando a consistência da mistura para ração animal, seja para aves, suínos ou bovinos.

Baixa manutenção: a carcaça reforçada e as vedações de rolos cônicos reduzem o desgaste, enquanto trocas simples de óleo (a cada 500-700 horas) mantêm o funcionamento suave.

Economia de custos: a vantagem de custo do 50% da TEBSA em relação às caixas de engrenagens originais significa que você obtém qualidade premium sem gastar muito, um fator essencial para o agronegócio argentino.

Suporte local: Nossa equipe de engenharia, sediada na Argentina, responde em 24 horas, oferecendo orientação especializada para instalação, manutenção ou personalização.

Esta caixa de engrenagens é uma parceira confiável para vagões misturadores de ração, garantindo desempenho consistente no diversificado cenário agrícola da Argentina, desde campos de soja até pastagens.

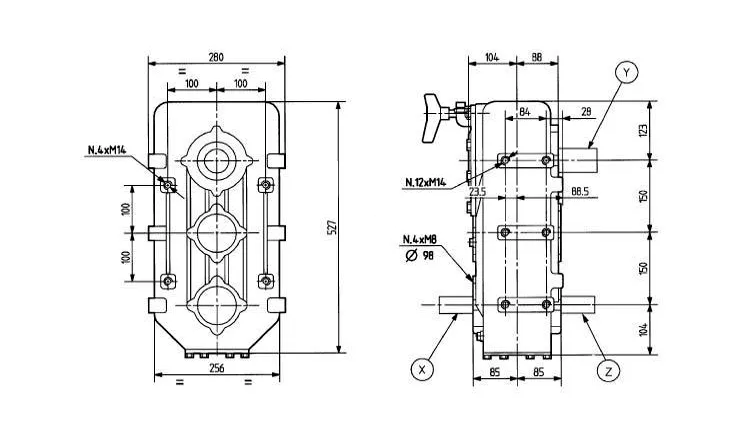

Especificações técnicas e características

A caixa de engrenagens de substituição TEBSA D732A foi projetada para precisão e potência, com especificações projetadas para atender às demandas de misturadores de alimentação horizontais. Abaixo, os principais detalhes:

| Descrição do produto |

Caixa de engrenagens do misturador de alimentação horizontal - Substituição da caixa de engrenagens Comer D732A 1:1/1.93:1

|

|---|---|

| Detalhes do produto |

|

| Faixa de aplicação |

Vagão de mistura

|

| Fator de razão |

1:1.93

|

| Consiste em |

|

| Potência máxima de entrada |

59 kW

|

| Potência máxima de saída |

80 HP

|

| Conexão 1 diâmetro externo |

1-3/8 polegadas

|

| Conexão 1 número de splines |

6

|

| Conexão 2 diâmetro externo |

60 milímetros

|

| Contém óleo |

Não

|

| Capacidade máx. de óleo |

5,6 l

|

| Intervalo máximo de troca de óleo |

500 horas

|

| Grau de viscosidade SAE do óleo |

80W-90

|

| Material da carcaça |

Ferro fundido GG25

|

| Peso |

63 kg

|

Recursos técnicos adicionais

- Usinagem de precisão: As engrenagens são fresadas e retificadas para uma transferência de potência suave, reduzindo ruído e desgaste.

- Tratamento térmico: Engrenagens carburadas aumentam a dureza, ideal para tarefas de mistura de ração de alta intensidade na Argentina.

- Sistema de vedação: As vedações de rolos cônicos evitam vazamentos, protegendo os componentes internos contra poeira e umidade em regiões úmidas como Entre Ríos.

Aplicações e Manutenção para Fazendas Argentinas

A caixa de engrenagens de substituição TEBSA D732A foi projetada para vagões misturadores de ração horizontais, um produto essencial na indústria pecuária argentina. Seja misturando ração para gado em Santa Fé ou aves em Mendoza, esta caixa de engrenagens garante uma mistura uniforme, essencial para a saúde animal e a eficiência da fazenda. Seus 80 HP de potência e 59 kW de potência de entrada são adequados para operações de médio a grande porte, enquanto a relação de transmissão 1:1,93 otimiza o torque para misturas de ração espessas.

Principais aplicações

| Aplicativo | Descrição | Palavras-chave relevantes |

|---|---|---|

| Mistura de ração para gado | Mistura milho, soja e silagem para gado leiteiro e de corte nos Pampas. | Caixa de engrenagens do misturador de ração para gado, caixa de engrenagens agrícola Argentina |

| Processamento de ração para aves | Lida com grãos finos para granjas avícolas em Buenos Aires. | Caixa de engrenagens do misturador de ração para aves, caixa de engrenagens de ferro fundido para ração |

| Produção de ração para suínos | Mistura rações ricas em proteínas para granjas de suínos em Córdoba. | Caixa de engrenagens para ração suína, caixa de engrenagens para misturador de ração durável |

Dicas de manutenção

Para manter a caixa de engrenagens em ótimas condições:

Configuração inicial: Encha com 5,6 litros de óleo 80W-90 antes de usar, pois ele é enviado sem óleo.

Trocas de óleo: Troque o óleo após 50-70 horas e depois a cada 500-700 horas ou anualmente.

Inspeções: Verifique se há vazamentos ou desgaste mensalmente, especialmente em regiões empoeiradas como La Pampa.

Alinhamento: Certifique-se de que a caixa de engrenagens e o misturador estejam alinhados para evitar tensão na conexão de 6 estrias de 1-3/8 pol.

Lubrificação: Use somente óleo 80W-90 aprovado pelo fabricante para manter a integridade da engrenagem.

A manutenção regular evita paradas, garantindo que seu misturador de ração permaneça produtivo durante as movimentadas temporadas de colheita na Argentina. A equipe da TEBSA está disponível 24 horas por dia, 7 dias por semana, para responder a perguntas ou fornecer peças de reposição, mantendo sua operação no caminho certo.

Sobre a TEBSA e nossas soluções agrícolas

Desde 1997, a TEBSA é líder na fabricação de caixas de engrenagens agrícolas na Argentina, oferecendo soluções confiáveis e econômicas para agricultores e operadores industriais. Com sede na Argentina, orgulhamo-nos de uma garantia de qualidade 100%, uma vantagem de custo 50% em relação às marcas originais e uma equipe de engenharia qualificada que responde em até 24 horas. Certificados pela ISO 9001-2015, utilizamos processos avançados como forjamento, cementação e retificação de precisão para produzir produtos duráveis e adaptados às necessidades agrícolas da Argentina.

Além da caixa de engrenagens do misturador de alimentação horizontal, a TEBSA oferece uma ampla gama de caixas de engrenagens agrícolas, incluindo:

Caixas de engrenagens de cortador rotativo: para corte e gerenciamento de resíduos de colheita.

Caixas de engrenagens para espalhadores de fertilizantes: para distribuição precisa de nutrientes.

Caixas de engrenagens de cultivador rotativo: Para preparação do solo em campos de soja e trigo.

Caixas de engrenagens de cortadores de grama: para controle pesado de vegetação.

Eixos de tomada de força: para transferência eficiente de potência em máquinas agrícolas.

Não importa se você está em Buenos Aires, Mendoza ou Santa Fé, a TEBSA é sua parceira de confiança para caixas de engrenagens agrícolas. Contate-nos hoje para saber mais sobre a caixa de engrenagens de substituição D732A ou explorar nossa linha completa de produtos.

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos