Caixa de engrenagens do cortador hidráulico – Substituição do Comer Código A-649A

A Caixa de Engrenagens para Cortadores Hidráulicos A-649A, projetada pela TEBSA na Argentina, é um componente vital para máquinas de corte hidráulicas que trabalham com materiais resistentes como metal, concreto e madeira. Desde 1997, a TEBSA fornece caixas de engrenagens confiáveis e de alta qualidade com garantia de qualidade 100%, tornando a A-649A uma escolha confiável para aplicações exigentes. Esta caixa de engrenagens transfere potência do motor hidráulico para a ferramenta de corte, utilizando engrenagens, rolamentos e vedações de precisão para reduzir a velocidade e aumentar o torque. Construída para durar, ela suporta as intensas tensões de corte, oferecendo uma vantagem de custo 50% em relação às marcas originais.

Projetado para tarefas pesadas, o A-649A prospera em setores como construção, silvicultura e reciclagem nas diversas paisagens da Argentina, de Buenos Aires aos contrafortes andinos. Sua construção robusta, com aço-liga e tratamentos térmicos avançados, como a cementação, garante um desempenho duradouro. A manutenção regular e a lubrificação adequada mantêm o seu funcionamento sem problemas, prolongando sua vida útil por anos de serviço confiável.

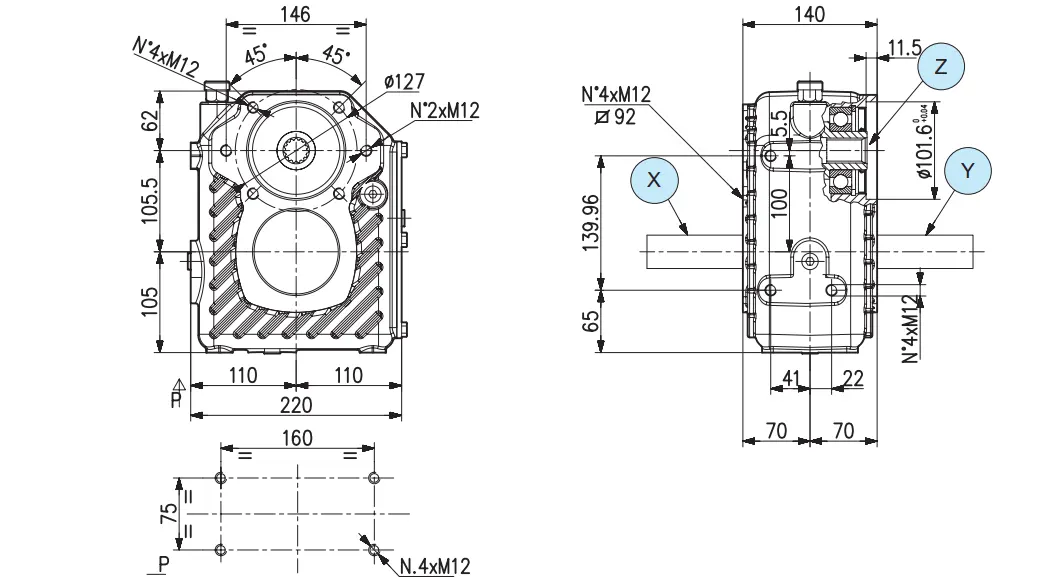

Especificações da caixa de engrenagens do cortador hidráulico A-649A

| eu | 4.23/3.00 |

| Não1[rotações por minuto] | 540 |

| P1[kW] | 40.4/44.0 |

| M2[Nm] | 172/265 |

Eixo X |

1'' 3/8 Z6 |

Eixo Z |

16/32'' DP Z13 16/32'' DP Z15 |

| Entrada | X |

Principais recursos e benefícios da caixa de engrenagens A-649A

A caixa de engrenagens do cortador hidráulico A-649A da TEBSA foi projetado para oferecer o melhor desempenho nos setores mais desafiadores da Argentina. Veja por que ele se destaca:

Saída de alto torque: Com classificações de torque de 172-265 Nm, o A-649A corta metal, concreto e madeira com facilidade, o que o torna ideal para cortes pesados em canteiros de obras ou usinas de reciclagem.

Construção durável: Feita com liga de aço e processada por meio de técnicas avançadas como forjamento e cementação, esta caixa de engrenagens resiste ao desgaste, mesmo nos ambientes exigentes da Argentina, como os terrenos rochosos de Mendoza.

Relações de transmissão versáteis: Oferecendo relações de transmissão de 4,23 e 3,00, ele se adapta a várias velocidades de corte, garantindo desempenho ideal para tarefas desde silvicultura na Patagônia até demolição em Buenos Aires.

Vedação confiável: Vedações de alta qualidade protegem os componentes internos contra poeira, detritos e vazamentos de fluido hidráulico, garantindo uma operação consistente em condições adversas.

Fácil manutenção: Projetado para manutenção simples, o A-649A permite acesso rápido a vedações e rolamentos, com a equipe de engenharia da TEBSA pronta para ajudar em 24 horas.

Economia de custos: Por 50% a menos que os modelos originais comparáveis, ele oferece desempenho premium sem estourar o orçamento, uma vantagem fundamental para as empresas argentinas.

| Recurso | Detalhes |

| Material | Aço Ligado com Carburação |

| Faixa de torque | 172-265 Nm |

| Relações de transmissão | 4.23, 3.00 |

| Aplicações | Construção, Silvicultura, Reciclagem |

Aplicações da caixa de engrenagens do cortador hidráulico A-649A na Argentina

A A-649A é uma máquina potente e versátil, adequada para diversos setores na Argentina. Sua capacidade de lidar com cortes de alta tensão a torna indispensável para:

- Construção: Corte de concreto e vergalhões para projetos de infraestrutura em cidades como Córdoba ou Rosário, onde o desenvolvimento urbano está crescendo.

- Silvicultura: Processamento de madeira nas densas florestas da Patagônia, onde a durabilidade em relação à resistência da madeira é essencial.

- Reciclagem: Trituração de metais e outros materiais em instalações de reciclagem, apoiando os crescentes esforços de sustentabilidade da Argentina.

- Demolição Industrial: Desmontagem de estruturas com precisão, ideal para projetos de reforma em Buenos Aires.

Esta caixa de engrenagens, combinada com máquinas de corte hidráulicas, proporciona potência consistente, seja em uma fazenda de soja nos Pampas ou em um canteiro de obras em Mendoza. Sua adaptabilidade a diferentes materiais — metal, concreto e madeira — a torna uma solução ideal para profissionais argentinos.

Para um desempenho ideal, combine o A-649A com os motores hidráulicos e ferramentas de corte da TEBSA. A lubrificação regular com óleos aprovados pelo fabricante e as verificações periódicas da integridade das vedações garantem que ele acompanhe as exigentes cargas de trabalho da Argentina. Seja você um empreiteiro, um engenheiro florestal ou um reciclador, o A-649A aumenta a eficiência e reduz o tempo de inatividade.

| Indústria | Material | Região |

| Construção | Concreto, Vergalhões | Córdoba, Rosário |

| Silvicultura | Madeira | Patagônia |

| Reciclagem | Metal | Buenos Aires |

Manutenção e cuidados para desempenho duradouro

Para manter a caixa de engrenagens do cortador hidráulico A-649A com o melhor desempenho, siga estas dicas de manutenção:

Inspeções regulares: Verifique se há vazamentos, rolamentos desgastados ou danos nas engrenagens a cada 100 horas de uso para detectar problemas precocemente.

Lubrificação: Utilize óleos hidráulicos de alta viscosidade, aprovados pelo fabricante, substituindo-os de acordo com as diretrizes da TEBSA para evitar atrito e superaquecimento.

Verificações de lacre: Inspecione as vedações para verificar se há desgaste, especialmente em condições de poeira ou umidade, como nos Pampas úmidos da Argentina ou nas regiões secas dos Andes.

Alinhamento: Certifique-se de que a caixa de engrenagens esteja alinhada corretamente com o motor e a ferramenta de corte para evitar tensões irregulares e prolongar a vida útil da engrenagem.

Limpeza: Remova os detritos da caixa de engrenagens após o uso em locais lamacentos ou empoeirados para manter a eficiência do resfriamento.

A equipe de engenharia da TEBSA, conhecida por responder em até 24 horas, pode orientá-lo na manutenção ou fornecer peças de reposição, como retentores e rolamentos. O cuidado adequado reduz o tempo de inatividade e mantém sua máquina de corte hidráulica funcionando perfeitamente, seja cortando concreto em Rosário ou madeira na Patagônia.

Para empresas que compram online, pesquise por "redutor de cortador hidráulico A-649A na Argentina" ou "redutor durável para corte de concreto" para encontrar as soluções da TEBSA. Nossa vantagem de custo 50% e a certificação ISO9001-2015 garantem qualidade premium a um preço acessível.

Sobre a TEBSA e nossas soluções agrícolas e industriais

Desde 1997, a TEBSA é líder na Argentina, fornecendo caixas de engrenagens e componentes de alto desempenho com garantia de qualidade 100%. Com sede na Argentina, combinamos fabricação avançada — forjamento, cementação e retificação de precisão — com uma vantagem de custo 50% em relação às marcas originais. Nossa certificação ISO9001-2015 e nossa equipe de atendimento 24 horas nos tornam um parceiro confiável para empresas em todo o país, de Buenos Aires a Mendoza.

Além da caixa de engrenagens do cortador hidráulico A-649A, a TEBSA oferece uma ampla gama de produtos para necessidades agrícolas e industriais:

- Caixas de engrenagens de cortador rotativo: Como o RC-61, ideal para cortadores de grama e cortes pesados.

- Caixas de engrenagens para espalhadores de fertilizantes: Para distribuição precisa de nutrientes em campos de soja e trigo.

- Caixas de engrenagens para cortadores de grama: Soluções duráveis para paisagismo e manejo de pastagens.

- Eixos de tomada de força: Transferência de potência confiável para tratores e implementos em toda a Argentina.

- Caixas de engrenagens do cortador de mangual: Perfeito para limpeza de vegetação difícil nos Pampas.

Seja você um agricultor, empreiteiro ou operador industrial, as soluções da TEBSA são feitas para durar. Entre em contato conosco hoje mesmo para explorar nossa linha completa ou solicitar um orçamento para a caixa de engrenagens do cortador hidráulico A-649A. Com a TEBSA, você escolhe confiabilidade, eficiência e valor incomparável para os trabalhos mais difíceis da Argentina.

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos