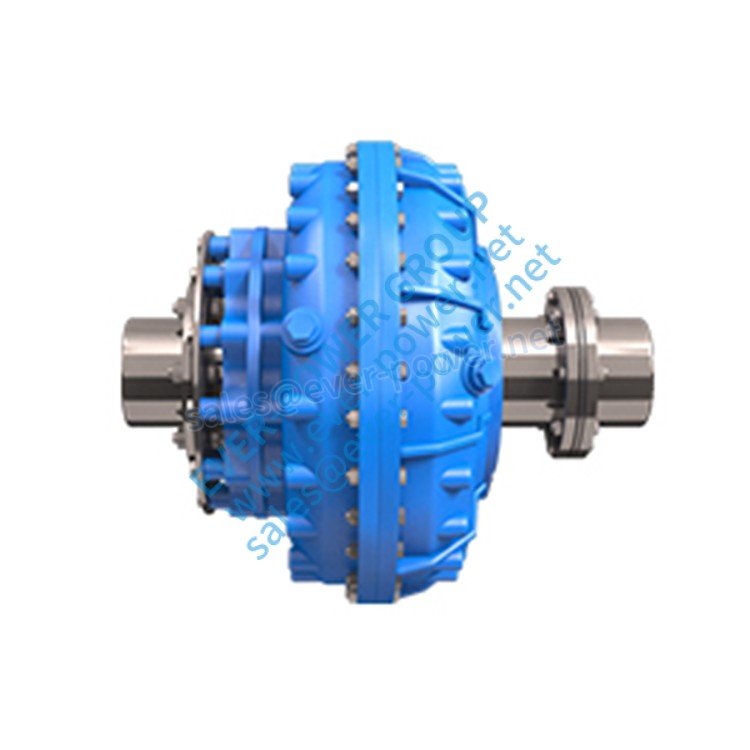

Acoplamentos de fluidos

Introdução aos acoplamentos de fluidos

Um acoplamento de fluido é um dispositivo que melhora a capacidade de partida de um motor elétrico, protege o motor contra sobrecarga, amortece choques, lida com flutuações de carga e vibrações torcionais, e equilibra e distribui cargas em caso de acionamentos multimotores. É amplamente utilizado em várias indústrias e aplicações.

Características dos acoplamentos de fluidos

- Melhora a capacidade de partida do motor elétrico

- Protege o motor contra sobrecarga

- Amortece choques, flutuações de carga e vibrações torcionais

- Permite balanceamento e distribuição de carga em acionamentos multimotores

Aplicações de acoplamentos de fluidos

- Transportadores de correia

- Transportadores raspadores

- Todos os tipos de transportadores

- Elevadores de caçamba

- Moinhos de bolas

- Elevadores

- Trituradores

- Escavadeiras

- Misturadores

- Alisadores

- Guindastes

- E muitos mais

Os acoplamentos de fluidos são essenciais nessas aplicações por sua capacidade de garantir uma operação suave e eficiente.

Seleção de acoplamentos de fluidos

Ao selecionar um acoplamento de fluido, é importante considerar a folha de dados técnicos e o gráfico de potência fornecidos. Esses recursos ajudam a determinar o tamanho adequado do acoplamento de fluido com base na potência transmitida e na velocidade do motor. Além disso, as dimensões das extremidades do eixo do motor e da máquina acionada (ou redutor) devem ser especificadas, incluindo diâmetro, tolerância ou ajuste, comprimento, largura e profundidade das chaves. Para requisitos especiais, como acoplamentos de fluido com polias de correia ou polias de freio, dados técnicos detalhados devem ser fornecidos.

YOXz é um tipo de acoplamento de fluido com uma roda móvel que é conectada a uma máquina de conexão de eixo elástico. Ele oferece três tipos de conexão e é conhecido por sua estrutura apertada e tamanho de eixo pequeno. Os encaixes YOXz têm um amplo uso e estrutura simples, tornando-os fáceis de usar em várias aplicações. O estilo de conexão do YOXz permite fácil instalação sem a necessidade de mover a máquina eletromotriz e a máquina de desaceleração. O tamanho do YOXz é determinado pelas especificações do cliente.

YOXp é outro tipo de acoplamento de fluido, projetado como um estilo de conexão com uma bandeja de correia e máquina de coincidência hidráulica. É adequado para equipamentos transportados por correia. O tamanho da conexão do eixo da máquina eletromotriz e a especificação detalhada e o tamanho da bandeja de correia devem ser fornecidos pelo cliente.

YOXf é um tipo de acoplamento de fluido que é conectado em ambos os lados. Ele tem um tamanho de eixo maior, mas uma estrutura simples, tornando-o fácil de consertar e emendar sem mover a máquina eletromotriz e a máquina de desaceleração. A máquina de conexão de eixo elástico relevante, tamanho de conexão e tamanho externo são semelhantes ao tipo YOXe.

Procedimentos adequados de instalação, manutenção e reparo devem ser seguidos ao lidar com acoplamentos de fluidos. Também é importante entender como substituir o acoplamento de fluidos, se necessário.

Outros produtos

Nossa empresa é especializada no fornecimento de vários produtos relacionados à indústria, incluindo engrenagens de plástico, caixas de engrenagens agrícolas, eixos de saída de potência, rodas dentadas, redutores de engrenagem sem-fim, engrenagens e cremalheiras, correntes destacáveis, polias e polias, caixas de engrenagens planetárias, polias de sincronização e buchas. Estamos comprometidos em fornecer produtos de alta qualidade a preços favoráveis e oferecer um serviço atencioso ao cliente. Damos as boas-vindas aos clientes para virem até nós com suas necessidades de personalização de desenho ou amostra.

Perguntas e respostas

1. Quais são as principais características dos acoplamentos de fluidos?

2. Em quais aplicações os acoplamentos de fluidos são comumente usados?

3. Como seleciono o tamanho correto do acoplamento de fluido?

4. Qual é a vantagem de usar acoplamentos de fluido YOXz?

5. Quais outros produtos sua empresa fornece?

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos