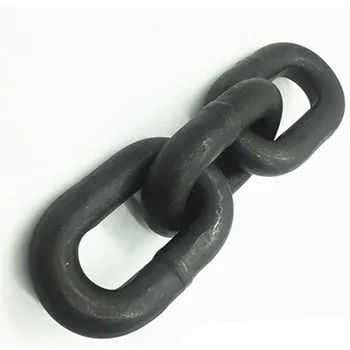

Black Oxidised G80 Chain

Black Oxidised G80 Chain

The Black Oxidised G80 Chain is a lifting chain with a black finish. It is made of high-quality alloy steel and undergoes a fully automated manufacturing process. This chain type has high tensile strength and complies with EN818, ISO3077, and AS2321 standards. In addition to the black finish, it is also available in powder coated, polished, and electroplated finishes. It is suitable for high-temperature applications.

All lashing chains are manufactured with fully automatic chain-making machines, resulting in clean welds of the chain links. The short links of this G80 chain are graded G80 tempered and made from AG90L. An internal heat treatment ensures consistent quality and a durable chain with the minimum required breaking strength. Each chain undergoes testing before hook assembly and painting. The G80 Short Chain Lashing Chains are black painted and black oxidized, providing a tough, durable, and smooth surface for each link. They are marked with YD8-x (x=diameter). Manufacturers are able to provide chains in custom colors and with additional markings upon request. The chains are packaged in sturdy drums and come with a factory certificate.

High Tensile Chain for Sale

When purchasing high-strength chains, it is important to select the correct grade based on workload limits. Chain grades are classified by the National Association of Chain Manufacturers and the American Society for Testing and Materials. Higher ratings indicate greater workload limits. It is vital to consider the "workload limit" of the chain, which is a designated safety measure. The chain's advertised rating by the manufacturer is only one-tenth of the actual math rating. For example, class 80 is 800 pounds, while class 120 is 1,200 pounds. Other factors to consider include the maximum stress the chain can safely handle, which is less than the ultimate tensile or breaking load, and the effects of gravity and other forces.

The high-strength chain is made of special material and has a unique square shape that provides increased strength compared to regular chains.

High-strength Drag Chain

A high-tension energy chain, or drag chain, is designed to handle heavy loads in a range of environments. It can withstand high temperatures and handle wet and dry materials. The chain's polyethylene bottom and return liner ensure smooth and continuous movement, accommodating various shapes and sizes. Energy chains are widely used in construction and industrial processes to protect hoses and cables from damage during machine movement, preventing accidents and downtime. They are available in different materials such as steel, aluminum, plastic, stainless steel, and nylon.

Energy chains offer greater flexibility compared to ordinary cables. They have a smaller diameter and are insulated with materials that provide excellent mechanical fatigue resistance and clogging resistance. Energy chains also exhibit high toughness, low resistivity, and do not heat up under rated load, making them suitable for mobile use.

Related Sprockets

Properly installed sprockets play a crucial role in the efficiency of a chain-driven motion system. They can carry heavy loads and are essential components in many chain-driven motion systems. When selecting a sprocket, it is important to consider the system's size and type of fit. Sprockets have a longer lifespan when equipped with "hardened teeth," which can triple the sprocket's durability.

Sprockets are toothed wheels that mesh with a chain as they rotate. They differ from gears because they do not mesh directly. Sprockets are used in various applications, from disposable cameras to professional bicycles and motor vehicles.

Our Advantage

- High-quality products at competitive pricing

- Wide variety of products available in various materials and sizes

- Products manufactured in an ISO9001:2008 certified factory

- Great customer service to answer all your questions

- Largest online selection of power transmission products

- High-quality made-to-order products

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos