Caixa de engrenagens do cortador hidráulico – Substituição do Comer Código A-640A

A caixa de engrenagens do cortador hidráulico A-640A, projetada por TEBSA na Argentina, é um componente robusto de transmissão de potência projetado para acionar as lâminas de corte de cortadores hidráulicos. Esta caixa de engrenagens transforma energia hidráulica em força rotacional, proporcionando desempenho confiável para tarefas de corte pesadas. Construído com engrenagens e rolamentos de precisão, ele lida com altos níveis de torque, garantindo uma operação suave. Desde 1997, a TEBSA é um fabricante confiável, oferecendo uma garantia de qualidade 100% e uma vantagem de custo 50% em relação às marcas originais, tornando o A-640A a melhor escolha para setores como agricultura, construção e mineração em toda a Argentina.

Ideal para cortar materiais resistentes, como plantações densas, vegetação lenhosa ou entulho de construção, o A-640A é um pilar fundamental da maquinaria pesada nas planícies dos Pampas argentinos e além. Sua construção durável, utilizando aço-liga e técnicas avançadas de forjamento, garante longevidade mesmo em condições adversas. Seja limpando plantações de soja em Córdoba ou administrando pastagens em Buenos Aires, esta caixa de engrenagens oferece eficiência e durabilidade, com o suporte de engenharia 24 horas da TEBSA.

Especificações da caixa de engrenagens do cortador hidráulico A-640A

| eu | 3.82 |

| Não1[rotações por minuto] | 540 |

| P1[kW] | 55.9 |

| M2[Nm] | 252 |

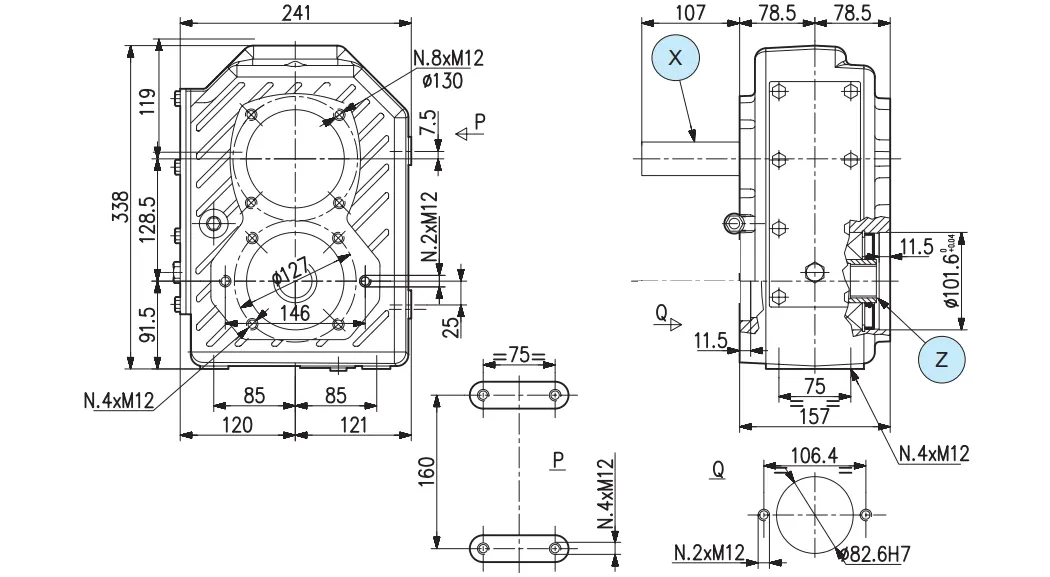

Eixo X |

1'' 3/8 Z6 |

Eixo Z |

16/32'' DP Z13 |

| Entrada | X |

Principais recursos e benefícios da caixa de engrenagens do cortador hidráulico A-640A

A caixa de engrenagens A-640A é uma solução de destaque para cortes pesados, oferecendo uma série de vantagens adaptadas às necessidades agrícolas e industriais da Argentina.

Alta capacidade de torque: Com um torque de 252 Nm, o A-640A corta materiais resistentes como madeira, grama grossa ou entulho de construção. Sua relação de transmissão de 3,82 garante a velocidade ideal da lâmina para um corte eficiente.

Materiais duráveis: Construída em aço-liga com tratamentos térmicos de carburação e nitretação, esta caixa de engrenagens resiste ao desgaste e à corrosão, mesmo nos climas subtropicais úmidos da Argentina. A carcaça passa por escurecimento e fosforização para maior proteção.

Entrega de energia suaveEngrenagens de precisão e rolamentos cônicos reduzem o atrito e a vibração, garantindo uma rotação consistente da lâmina. Isso minimiza o desgaste das máquinas conectadas, prolongando a vida útil do equipamento.

Aplicações Versáteis: De tarefas agrícolas, como limpeza de campos de milho, a operações de mineração em San Juan, o A-640A adapta-se a diversos setores. Sua potência de entrada de 540 rpm e 55,9 kW são compatíveis com uma ampla gama de cortadores hidráulicos.

Eficiência de custos: A fabricação estratégica da TEBSA proporciona uma economia de custos do 50% em comparação ao equipamento original, tornando o A-640A uma atualização acessível para agricultores e empreiteiros.

Fácil manutenção: Projetada com componentes acessíveis, a caixa de engrenagens permite trocas de óleo e retentores simples, com o suporte da equipe técnica 24 horas da TEBSA na Argentina.

| Recurso | Beneficiar |

| Construção em liga de aço | Resiste às duras condições agrícolas argentinas |

| Alto torque (252 Nm) | Avança em plantações densas como a soja |

| Rolamentos de rolos cônicos | Garante uma operação suave e com baixa vibração |

| Vantagem de custo 50% | Acessível para pequenas e grandes fazendas |

Aplicações do A-640A nas indústrias argentinas

A caixa de engrenagens do cortador hidráulico A-640A se destaca no diversificado cenário industrial da Argentina, especialmente nos setores de agricultura, construção e mineração. Seu design robusto e alto torque a tornam um componente essencial para tarefas exigentes.

- Agricultura: Em regiões produtoras de grãos da Argentina, como os Pampas, o A-640A aciona cortadores que limpam plantações de soja, trigo e milho. Ele processa vegetação densa e resíduos agrícolas, aumentando a produtividade dos agricultores em Rosário ou Santa Fé. A compatibilidade da caixa de engrenagens com os sistemas hidráulicos acionados por tratores garante uma integração perfeita com os equipamentos locais.

- Construção: Para preparação de terrenos em Buenos Aires ou Córdoba, o A-640A aciona cortadores que cortam raízes, arbustos e detritos. Sua durabilidade atende às demandas rigorosas de projetos de construção urbana e rural.

- Mineração: Nos centros de mineração de San Juan, a caixa de engrenagens auxilia os cortadores a romper terrenos rochosos ou com sobrecargas difíceis. Sua estrutura em aço-liga e engrenagens tratadas termicamente suportam as condições abrasivas das operações a céu aberto.

O eixo de entrada 1'' 3/8 Z6 e o eixo de saída 16/32'' DP Z13 do A-640A garantem compatibilidade com cortadores hidráulicos padrão, tornando-o uma escolha versátil para compradores que procuram “caixa de engrenagens de cortador hidráulico à venda na Argentina” ou “confiável caixa de engrenagens agrícola fornecedor.”

Dicas de manutenção e longevidade para o A-640A

Para manter o A-640A com o melhor desempenho, a TEBSA recomenda manutenção regular, aproveitando nossos processos certificados pela ISO9001-2015 para garantia de qualidade.

Verificações de óleo: Inspecione os níveis de lubrificante a cada 50 horas de operação, utilizando óleo de alta viscosidade aprovado pelo fabricante para manter o desempenho da engrenagem. Troque o óleo a cada 500 horas ou anualmente.

Inspeções visuais: Procure mensalmente por sinais de vazamentos, rachaduras ou desgaste na carcaça. A detecção precoce evita paradas dispendiosas em épocas de colheita intensas.

Cuidados com rolamentos e vedações: Limpe e lubrifique o eixo de entrada periodicamente para garantir uma transferência de potência eficiente. Substitua as vedações conforme necessário para evitar contaminação.

Alinhamento: Certifique-se de que a caixa de engrenagens e o cortador estejam devidamente alinhados para evitar desgaste irregular. O desalinhamento pode causar calor excessivo e danos à engrenagem.

Armazenar: Quando não estiver em uso, guarde a caixa de engrenagens em um local seco e coberto para protegê-la do clima úmido da Argentina, especialmente em regiões costeiras como Mar del Plata.

Seguindo essas etapas, agricultores e operadores na Argentina podem maximizar a vida útil do A-640A, minimizando os custos de reparo e mantendo a eficiência máxima para tarefas como “caixa de engrenagens de cortador hidráulico para colheita de soja”.

Sobre a TEBSA e nossa linha de caixas de engrenagens agrícolas

Desde 1997, a TEBSA é líder na Argentina, fornecendo caixas de engrenagens agrícolas de alto desempenho com garantia de qualidade 100%. Com sede na Argentina, combinamos fabricação avançada — forjamento, fundição e tratamentos térmicos como carbonitretação — com uma equipe de engenharia talentosa que responde em até 24 horas. Nossa certificação ISO9001-2015 reforça nosso compromisso com a excelência, enquanto nossa vantagem de custo 50% nos torna um parceiro confiável para agricultores e operadores industriais em Buenos Aires, Córdoba e outras cidades.

Além da caixa de engrenagens do cortador hidráulico A-640A, a TEBSA oferece uma ampla gama de soluções agrícolas, incluindo:

- Caixas de engrenagens de cortador rotativo: Como o RC-61, ideal para cortes pesados.

- Caixas de engrenagens para espalhadores de fertilizantes: Para distribuição precisa de nutrientes em campos de soja e trigo.

- Caixas de engrenagens para escavadeiras de postes: Para cercas e plantios eficientes nos Pampas da Argentina.

- Caixas de engrenagens de cortadores de mangual: Para gerenciamento versátil da vegetação.

- Eixos de tomada de força: Transferência de energia durável para vários implementos agrícolas.

Não importa se você está procurando por “fabricante de caixa de engrenagens agrícolas na Argentina” ou “comprar caixa de engrenagens para cortadores hidráulicos online”, a TEBSA oferece soluções confiáveis e econômicas, adaptadas às suas necessidades. Contate-nos hoje para explorar nosso catálogo completo ou solicitar um orçamento!

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos