Eixo de transmissão hidráulica EP-MDH-40 para caixa de engrenagens

O Eixo de Acionamento Hidráulico EP-MDH-40, também conhecido como mancal, é um componente crítico de caixas de engrenagens agrícolas, projetado para oferecer desempenho robusto em aplicações exigentes. Fabricado por TEBSA, fornecedor confiável da Argentina desde 1997, este fuso garante a transmissão de potência perfeita em máquinas utilizadas na agricultura, construção, silvicultura, metalurgia e proteção ambiental. Com garantia de qualidade 100% e vantagem de custo 50% em relação às marcas originais, o EP-MDH-40 da TEBSA foi desenvolvido para oferecer durabilidade e eficiência nas diversas indústrias da Argentina, desde as planícies dos Pampas até os polos industriais de Buenos Aires e Córdoba.

Fabricado com precisão, o EP-MDH-40 utiliza materiais de alta qualidade, como aço-liga 20CrMnTi para engrenagens e aço-liga 42CrMo para eixos, processados por meio de técnicas avançadas como têmpera, cimentação e têmpera. Sua carcaça em ferro fundido ou ferro dúctil resiste a condições adversas, tornando-o ideal para tarefas pesadas, como colheita de soja ou preparação de canteiros de obras. Com design compacto, baixo ruído (60-68 dB) e alta eficiência (98%), este fuso atende às necessidades de agricultores, empreiteiros e operadores industriais na Argentina.

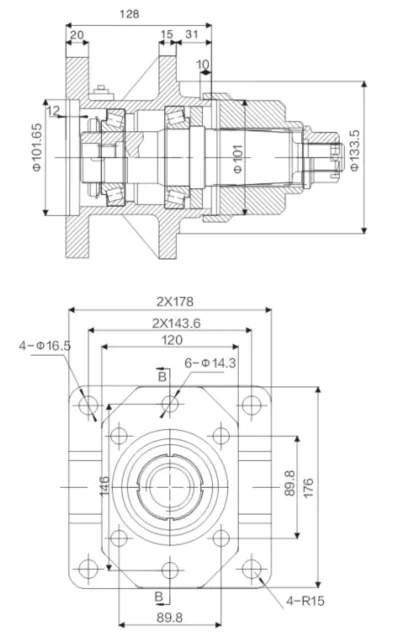

Especificações técnicas do fuso de acionamento hidráulico EP-MDH-40

O EP-MDH-40 foi projetado para oferecer precisão e confiabilidade. Abaixo estão suas principais especificações:

| Material da caixa | Ferro fundido/ferro dúctil |

| Dureza da carcaça | HBS190-240 |

| Material da engrenagem | Aço de liga 20CrMnTi |

| Dureza da superfície das engrenagens | HRC58~62 |

| Dureza do núcleo da engrenagem | HRC33~40 |

| Material do eixo de entrada/saída | Aço de liga 42CrMo |

| Dureza do eixo de entrada/saída | HRC25~30 |

| Precisão de usinagem de engrenagens | Retificação precisa, grau 6 a 5 |

| Óleo lubrificante | GB L-CKC220-460, Concha Omala220-460 |

| Tratamento térmico | Temperamento, Cimentação, Têmpera |

| Eficiência | 98% |

| Ruído (MÁX.) | 60~68 dB |

| Vibração | ≤20µm |

| Retaliação | ≤20 minutos de arco |

| Marca de Rolamentos | Rolamentos de marca de topo da China, HRB/LYC/ZWZ/C&U, ou SKF, FAG, INA, NSK |

| Marca do retentor de óleo | NAK (Taiwan) ou outras marcas solicitadas |

Aplicações e benefícios do fuso de acionamento hidráulico EP-MDH-40

O EP-MDH-40 é um componente versátil, desenvolvido sob medida para diversos setores na Argentina, oferecendo desempenho incomparável em ambientes exigentes. Suas aplicações abrangem agricultura (por exemplo, colheita de soja e milho nos Pampas), construção (preparação de terrenos em Buenos Aires), silvicultura (processamento de madeira em Misiones), processamento de metais (oficinas industriais em Rosário) e proteção ambiental (sistemas de gerenciamento de resíduos). Abaixo, seus principais benefícios:

Alta durabilidade: As engrenagens de liga de aço 20CrMnTi, com dureza superficial de HRC58-62, resistem ao desgaste mesmo nos climas subtropicais úmidos ou nas planícies empoeiradas da Argentina.

Transferência de potência eficiente: com eficiência 98%, minimiza a perda de energia, reduzindo os custos de combustível para tratores e máquinas.

Baixa manutenção: engrenagens retificadas com precisão (grau 6-5) e retentores de óleo NAK mantêm a manutenção simples, com o suporte técnico 24 horas da TEBSA.

Operação silenciosa: níveis de ruído de 60-68 dB garantem um ambiente de trabalho confortável, essencial para longas horas em campo.

Economia de custos: a vantagem de custo do 50% da TEBSA torna o EP-MDH-40 uma atualização acessível para agricultores e empreiteiros argentinos.

O EP-MDH-40 integra-se perfeitamente em caixas de engrenagens agrícolas, aprimorando o desempenho de máquinas como cortadores rotativos, roçadeiras e motocultivadores. Seu design robusto suporta alto torque e cargas pesadas, tornando-o uma escolha confiável para tarefas como limpeza de pastagens ou processamento de componentes metálicos.

Casos de uso específicos da aplicação

Para ilustrar sua versatilidade, veja como o EP-MDH-40 atende a diferentes setores:

| Indústria | Aplicativo | Beneficiar |

|---|---|---|

| Agricultura | Colheita de soja em Córdoba | Alto torque para corte de colheitas pesadas |

| Construção | Limpeza de terrenos em Buenos Aires | A carcaça durável resiste ao impacto de detritos |

| Silvicultura | Processamento de madeira em Misiones | Baixa vibração para corte de precisão |

Características técnicas e manutenção do EP-MDH-40

O EP-MDH-40 se destaca por sua engenharia avançada, projetada para atender às necessidades da indústria argentina. Suas principais características técnicas incluem:

Excelência do material: engrenagens feitas de liga de aço 20CrMnTi e eixos de 42CrMo garantem resistência e resistência à corrosão, vitais para os climas variados da Argentina.

Engenharia de precisão: retificação precisa (grau 6-5) e baixa folga (≤20Arcmin) proporcionam operação suave, reduzindo o desgaste nos componentes conectados.

Tratamento térmico: processos como cimentação e têmpera melhoram a dureza da engrenagem (HRC58-62) e a tenacidade do núcleo (HRC33-40), ideal para tarefas de alta carga.

Componentes de primeira linha: rolamentos de marcas confiáveis como SKF, FAG ou HRB/LYC da China, combinados com retentores de óleo NAK, garantem confiabilidade a longo prazo.

Lubrificação: Compatível com óleos GB L-CKC220-460 ou Shell Omala220-460, mantendo o desempenho em condições extremas.

Para manter o EP-MDH-40 em ótimas condições, siga estas dicas de manutenção:

Inspeções regulares: verifique se há vazamentos de óleo ou danos no alojamento a cada 500 horas de operação.

Trocas de óleo: Troque o óleo lubrificante a cada 1.000 horas ou 410 a 420 horas, usando óleos aprovados pela TEBSA, como Shell Omala 220-460.

Verificações de rolamentos: inspecione os rolamentos quanto a desgaste durante a manutenção anual para evitar paradas inesperadas.

Alinhamento: garanta o alinhamento adequado com a caixa de engrenagens para evitar vibração ou desgaste das engrenagens.

Limpeza: Mantenha o eixo livre de detritos, especialmente em regiões empoeiradas como os Pampas.

Seguindo essas etapas, os operadores argentinos podem estender a vida útil do EP-MDH-40, garantindo um desempenho confiável por anos.

Cronograma de manutenção

Para maior clareza, aqui está um cronograma de manutenção recomendado:

| Tarefa | Freqüência |

|---|---|

| Inspecionar se há vazamentos/danos | A cada 500 horas |

| Trocar óleo lubrificante | A cada 1.000 horas |

| Verifique os rolamentos | Anualmente |

Sobre a TEBSA e nossas soluções agrícolas

Desde 1997, a TEBSA, sediada na Argentina, é líder na fabricação de componentes agrícolas e industriais, fornecendo soluções confiáveis e econômicas em todo o mundo. Nosso compromisso com a garantia de qualidade 100%, a economia de custos 50% em comparação com as marcas originais e uma equipe de engenharia ágil (com feedback 24 horas) nos torna um parceiro confiável para agricultores, empreiteiros e operadores industriais. Certificados pela ISO 9001-2015, utilizamos processos avançados de fabricação, como forjamento, tratamento térmico e retificação de precisão, para produzir produtos duráveis e adaptados às necessidades únicas da Argentina, desde plantações de soja em Córdoba até canteiros de obras em Buenos Aires.

Além do fuso de acionamento hidráulico EP-MDH-40, a TEBSA oferece uma ampla gama de caixas de engrenagens e componentes agrícolas, incluindo:

Caixas de engrenagens de cortador rotativo: como o RC-61, ideal para cortes pesados no manejo de pastagens.

Caixas de engrenagens para espalhadores de fertilizantes: para distribuição precisa em lavouras.

Caixas de engrenagens para cortadores de grama: para corte versátil nos terrenos variados da Argentina.

Caixas de engrenagens para escavadeiras de postes: para cercas e plantio eficientes.

Eixos de tomada de força: para transferência confiável de potência em tratores e implementos.

Nossos produtos são projetados para suportar os ambientes desafiadores da Argentina, desde regiões subtropicais úmidas até planícies áridas, garantindo máxima produtividade e segurança. Contato Entre em contato com a TEBSA hoje mesmo para explorar nosso catálogo completo ou solicitar um orçamento para o EP-MDH-40 ou outras soluções.

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos