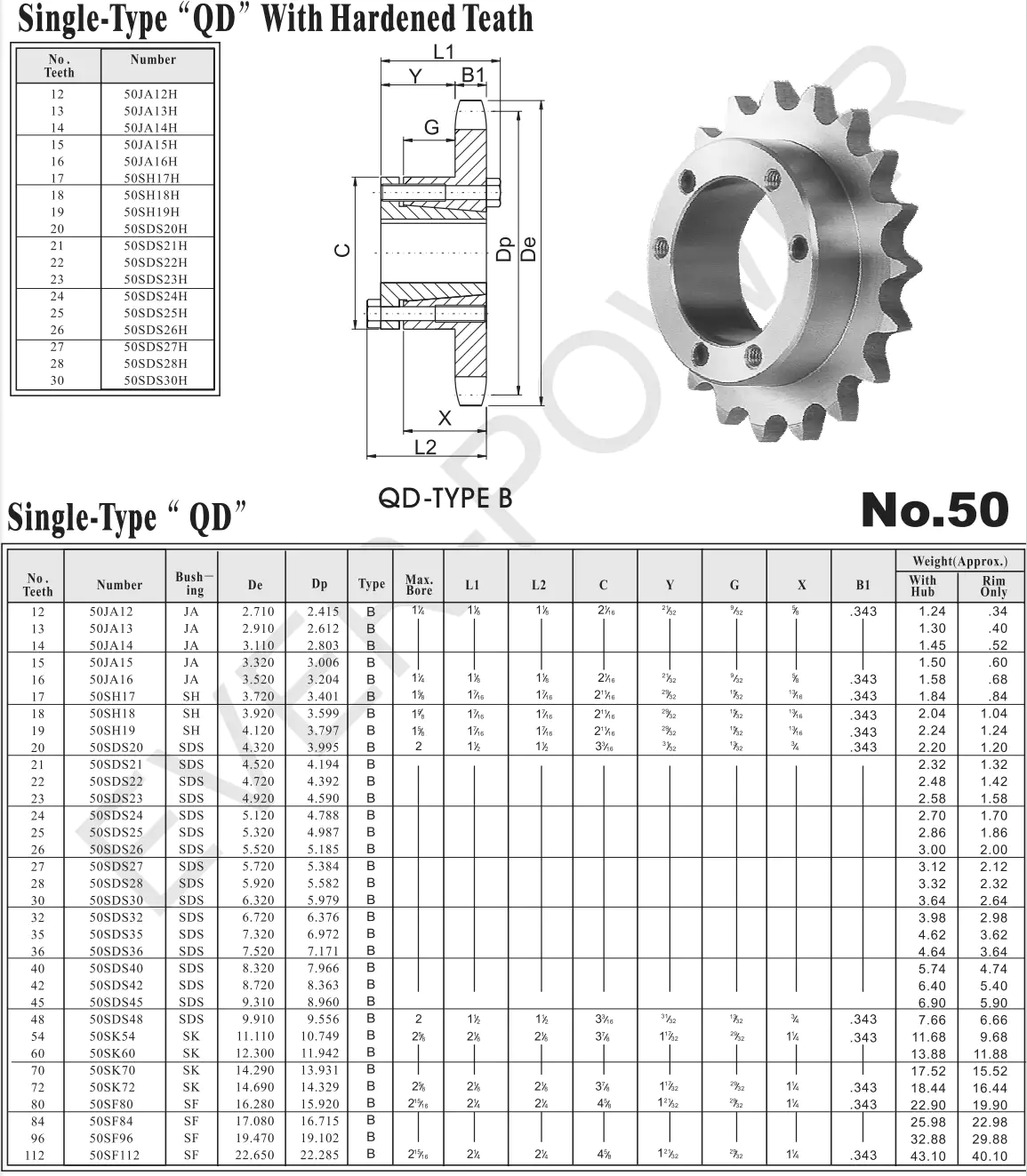

QD Sprocket No.50 Tipo Único

QD Sprocket No.50 Tipo Único

A roda dentada QD nº 50 tipo simples é uma roda dentada versátil comumente usada em sistemas de transmissão de potência. Ela desempenha um papel crucial na transferência de potência de um dispositivo para outro. Ao contrário das rodas dentadas tradicionais, a roda dentada QD nº 50 tipo simples oferece uma maneira simples e eficaz de montar uma roda dentada em um eixo sem a necessidade de uma chaveta. Este design inovador a tornou uma escolha popular entre engenheiros e fabricantes.

Introdução

A Roda Dentada QD nº 50 Tipo Simples é um componente essencial em sistemas de transmissão de potência. Ela consiste em duas partes principais: a roda dentada e a bucha. A roda dentada é uma roda dentada que se engata a uma corrente, enquanto a bucha é uma luva que se encaixa sobre o eixo e fixa a roda dentada no lugar. Juntos, eles formam um sistema de transmissão de potência confiável e eficiente.

Cenários de uso comum

A roda dentada QD nº 50 tipo simples é aplicada em diversos setores e máquinas que exigem transmissão de potência. Alguns cenários comuns em que esta roda dentada é utilizada incluem:

- Transportadores: rodas dentadas QD são frequentemente empregadas em sistemas transportadores para facilitar a movimentação de materiais.

- Máquinas industriais: são utilizadas em vários tipos de máquinas industriais, como equipamentos de fabricação, máquinas de embalagem e muito mais.

- Movimentação de materiais: rodas dentadas QD são comumente encontradas em sistemas de movimentação de materiais, como empilhadeiras, guindastes e guinchos.

- Equipamentos agrícolas: São usados em máquinas agrícolas, como tratores, colheitadeiras e cultivadores.

Histórico do produto

A Roda Dentada QD nº 50 Tipo Único possui uma rica história que remonta ao desenvolvimento de sistemas de transmissão de potência. Com os avanços em tecnologia e engenharia, os processos de projeto e fabricação dessas rodas dentadas evoluíram para atender às necessidades em constante mudança das indústrias em todo o mundo.

Classificação do produto

A roda dentada QD nº 50 tipo simples se enquadra na categoria de rodas dentadas com corrente de rolos. Essas rodas dentadas são projetadas especificamente para trabalhar em conjunto com correntes de rolos, facilitando a transferência de potência suave e confiável.

Vantagens da roda dentada QD nº 50 tipo simples

- Fácil instalação: as rodas dentadas QD podem ser instaladas de forma rápida e fácil, sem a necessidade de ferramentas especiais ou treinamento.

- Alta capacidade de carga: graças ao seu design de furo cônico, as rodas dentadas QD podem suportar altas cargas e distribuí-las uniformemente pelo eixo, reduzindo o risco de danos ou falhas.

- Design padronizado: as rodas dentadas QD têm um design padronizado, tornando-as compatíveis com uma ampla gama de componentes de transmissão de potência.

- Tamanho compacto: com seu design compacto, as rodas dentadas QD ocupam menos espaço, tornando-as adequadas para aplicações onde o espaço é limitado.

- Baixo custo de manutenção: as rodas dentadas QD exigem lubrificação mínima e são fáceis de substituir se danificadas ou desgastadas, resultando em baixos custos de manutenção.

Materiais de produtos disponíveis

A roda dentada QD nº 50 tipo único está disponível em vários materiais, incluindo:

- Aço: As rodas dentadas de aço oferecem excelente resistência e durabilidade, tornando-as adequadas para aplicações pesadas.

- Aço inoxidável: rodas dentadas de aço inoxidável são resistentes à corrosão e são comumente usadas em ambientes com alta umidade ou exposição a produtos químicos.

- Alumínio anodizado: As rodas dentadas de alumínio anodizado são leves e oferecem boa resistência à corrosão.

Instalação, Manutenção e Reparo

A instalação, manutenção e reparo da Roda Dentada QD nº 50 Tipo Único é um processo simples. Veja as etapas envolvidas:

- Instalação:

- Prepare as ferramentas e materiais necessários.

- Limpe as superfícies do eixo e da roda dentada.

- Posicione a roda dentada no eixo.

- Instale a bucha QD no eixo.

- Aperte firmemente a bucha QD no eixo.

- Verifique o alinhamento e o torque para garantir uma instalação correta.

- Manutenção:

- Inspecione regularmente a roda dentada e a bucha para verificar se há desgaste ou danos.

- Mantenha a roda dentada e a bucha limpas e livres de detritos.

- Aplique lubrificação conforme as recomendações do fabricante.

- Reparar:

- Se a roda dentada ou a bucha estiverem danificadas, substitua-as por novas com as mesmas especificações.

- Siga as etapas de instalação mencionadas acima para instalar corretamente os novos componentes.

Outros negócios de produtos da empresa

Nossa empresa é especializada no fornecimento de uma ampla gama de engrenagens plásticas industriais e componentes relacionados. Nossos produtos incluem:

- Caixas de engrenagens agrícolas

- Eixos de saída de potência

- Acoplamentos Hidráulicos

- Redutores de engrenagem sem-fim

- Cremalheiras de engrenagem

- Correntes removíveis

- Polias e Roldanas

- Caixas de engrenagens planetárias

- Polias de sincronização

- Buchas

Perguntas frequentes

1. O que é uma roda dentada QD?

Uma roda dentada QD é um tipo de roda dentada que pode ser montada em um eixo sem a necessidade de uma chaveta. Ela oferece uma solução simples e eficiente para sistemas de transmissão de potência.

2. O que é uma bucha QD?

Uma bucha QD é uma luva que se encaixa sobre um eixo e mantém a roda dentada firmemente no lugar. Ela elimina a necessidade de uma chaveta e proporciona uma conexão confiável.

3. Quais são as vantagens das buchas QD?

As buchas QD oferecem diversas vantagens, incluindo fácil instalação e remoção, alta capacidade de carga, design padronizado, tamanho compacto e baixos custos de manutenção. Essas características as tornam ideais para diversas aplicações de transmissão de potência.

4. Como instalar uma bucha QD?

Para instalar uma bucha QD, siga estas etapas:

- Prepare as ferramentas e materiais necessários.

- Limpe as superfícies do eixo e da roda dentada.

- Posicione a roda dentada no eixo.

- Deslize a bucha QD no eixo.

- Aperte firmemente a bucha QD no eixo.

- Verifique o alinhamento e o torque para garantir uma instalação correta.

5. Qual é o processo de fabricação das rodas dentadas QD?

O processo de fabricação de rodas dentadas QD envolve várias etapas:

- Preparar as matérias-primas.

- Corte os materiais no formato desejado.

- Forjar ou fundir a roda dentada.

- Usine a roda dentada de acordo com as especificações necessárias.

- Coloque os dentes na roda dentada.

- Trate termicamente a roda dentada para maior durabilidade.

- Aplique tratamento de superfície para proteger contra corrosão.

- Realizar inspeções de qualidade para garantir a qualidade do produto.

Autor: lmc

Aviso Legal: Todo o conteúdo desta página é proveniente da internet e serve apenas como referência para a seleção de produtos. Nossos produtos são acessórios e não peças de reposição originais. Não somos os detentores da marca registrada original mencionada no conteúdo. Nossos acessórios podem ser perfeitamente compatíveis com as peças de reposição originais. Caso necessite de peças de reposição originais, entre em contato com a fábrica para efetuar a compra.

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos