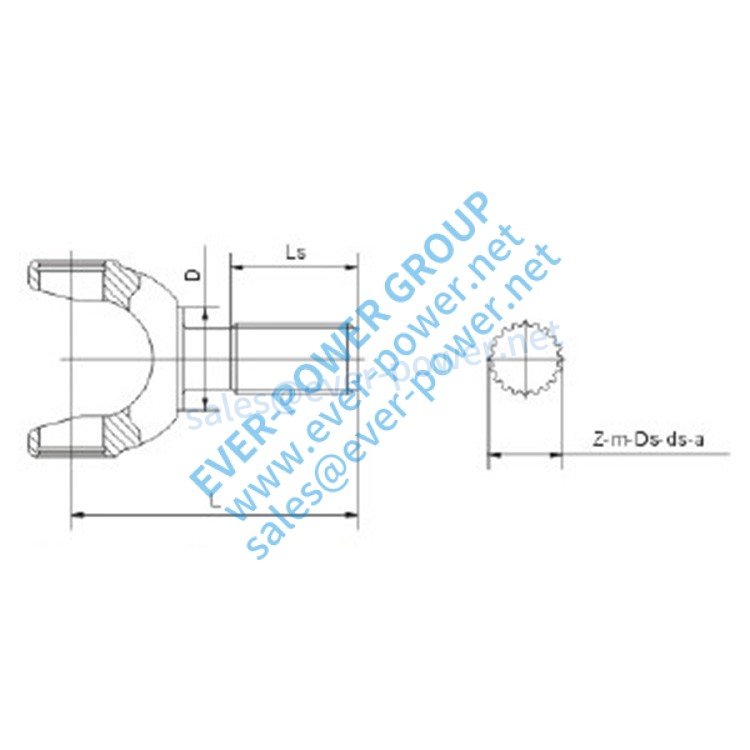

Garfo de eixo estriado (SS)

Garfo de eixo estriado (SS): o componente versátil de transmissão de potência

O garfo com eixo estriado (SS) é um componente crucial utilizado em diversos sistemas de transmissão de potência em diversos setores. Reconhecido por sua durabilidade e eficiência, este produto tem sido amplamente adotado em diversas aplicações. Neste artigo, exploraremos os cenários de uso comuns, o histórico, a classificação, as vantagens e as opções de materiais do garfo com eixo estriado SS. Também forneceremos informações sobre os procedimentos de instalação, manutenção, reparo e substituição.

Cenários de uso comum

- Indústria automotiva: O garfo com eixo estriado SS desempenha um papel vital nas transmissões manuais, garantindo operações suaves de troca de marchas.

- Fabricação de máquinas: É amplamente utilizado em máquinas com eixos rotativos, permitindo a transferência de torque e movimento rotativo.

- Equipamentos de construção: O garfo com eixo estriado SS é essencial em máquinas pesadas, como escavadeiras, permitindo controle preciso sobre sistemas hidráulicos.

- Automação industrial: Encontra aplicações em sistemas robóticos, garantindo controle de movimento preciso e confiável.

História e Classificação

O desenvolvimento de garfos com eixo estriado remonta ao início do século XX, quando a necessidade de transmissão de potência eficiente se tornou evidente. Com o tempo, diversos designs e configurações surgiram, atendendo a requisitos específicos. Algumas classificações comuns incluem:

- Garfos de eixo estriado paralelo

- Garfos de eixo estriado envolvente

- Garfos de eixo estriado helicoidal

- Garfos de eixo estriado esférico

Vantagens

- Excelente transmissão de torque: o garfo com eixo estriado SS garante transferência de potência eficiente, minimizando a perda de energia.

- Alta precisão: Seu design permite um posicionamento preciso, possibilitando uma operação suave e confiável.

- Maior durabilidade: feito de materiais de alta qualidade, o garfo com eixo estriado SS apresenta excelente resistência ao desgaste, garantindo desempenho a longo prazo.

- Fácil instalação: O design padronizado e a compatibilidade com vários sistemas simplificam os processos de instalação.

- Baixa manutenção: com os devidos cuidados, o garfo com eixo estriado SS requer manutenção mínima, reduzindo o tempo de inatividade.

Opções de materiais

O garfo com eixo estriado em aço inoxidável pode ser fabricado com diferentes materiais, dependendo dos requisitos específicos da aplicação. As opções de materiais comuns incluem:

- Aço: Oferece alta resistência e durabilidade, adequado para aplicações pesadas.

- Alumínio: Oferece propriedades leves, ideal para aplicações onde a redução de peso é essencial.

- Aço inoxidável: garante excelente resistência à corrosão, tornando-o adequado para ambientes desafiadores.

Instalação, Manutenção, Reparo e Substituição

Instalar, manter, reparar e substituir garfos de eixo estriado SS pode ser um processo simples se as seguintes diretrizes forem seguidas:

- Instalação: Alinhe cuidadosamente o eixo e o garfo, garantindo o engate correto. Use valores de torque adequados durante a fixação para evitar danos.

- Manutenção: Inspecione regularmente o garfo do eixo estriado em busca de sinais de desgaste ou danos. Mantenha-o limpo e devidamente lubrificado para manter o desempenho ideal.

- Reparar: Em caso de danos, consulte um profissional ou consulte as instruções do fabricante para procedimentos de reparo. Evite usar garfos com eixo estriado danificados, pois podem comprometer a eficiência e a segurança do sistema.

- Substituição: Ao substituir um garfo com eixo estriado, certifique-se de que ele seja compatível com o sistema existente. Siga os procedimentos de instalação adequados para garantir o desempenho ideal.

Outros produtos da empresa

Além do garfo com eixo estriado em aço inoxidável, nossa empresa é especializada no fornecimento de diversos componentes de engrenagens plásticas de alta qualidade utilizados em diversos setores. Nossa linha de produtos inclui caixas de engrenagens agrícolas, eixos de saída de potência, rodas dentadas, acoplamentos hidráulicos, redutores de engrenagem helicoidal, engrenagens e cremalheiras, correntes destacáveis, polias e polias, caixas de engrenagens planetárias, polias sincronizadoras, buchas e muito mais. Temos o compromisso de fornecer produtos de alta qualidade a preços competitivos, além de um atendimento excepcional ao cliente. Seja para produtos padrão ou soluções personalizadas com base em suas necessidades específicas, estamos aqui para atendê-lo.

Perguntas e respostas:

- P: Quais são as vantagens de usar um garfo com eixo estriado SS em aplicações automotivas?

- UM: O garfo com eixo estriado SS garante operações de troca de marchas precisas e suaves, melhorando a experiência geral de direção e reduzindo problemas relacionados à transmissão.

- P: O garfo com eixo estriado SS pode ser usado em ambientes altamente corrosivos?

- UM: Sim, ao optar por uma variante de aço inoxidável, o garfo com eixo estriado SS oferece excelente resistência à corrosão, tornando-o adequado para ambientes desafiadores.

- P: Com que frequência devo inspecionar e fazer a manutenção do garfo do eixo estriado SS?

- UM: Inspeções e manutenções regulares devem ser realizadas de acordo com as instruções do fabricante. No entanto, recomenda-se inspecionar o garfo do eixo estriado pelo menos uma vez a cada seis meses ou com mais frequência em condições operacionais exigentes.

- P: Há alguma precaução específica a ser considerada durante a instalação?

- UM: Sim, durante a instalação, é crucial garantir o alinhamento e o engate adequados entre o eixo e o garfo. Além disso, usar os valores de torque recomendados e seguir as diretrizes de instalação é essencial para o desempenho e a durabilidade ideais.

- P: Posso personalizar o garfo com eixo estriado SS com base em minhas necessidades específicas?

- UM: Sim, nossa empresa oferece serviços de personalização para o garfo com eixo estriado em aço inoxidável. Podemos trabalhar com você para projetar e fabricar um produto que atenda às suas necessidades e especificações exclusivas.

Sobre nós

Nós garantimos produtos de alta qualidade aos melhores preços na China! Pedidos especiais são bem-vindos, e se você estiver interessado em algum dos nossos produtos, sinta-se à vontade para entrar em contato para obter informações mais detalhadas. Nós garantimos que nossos produtos são seguros, de alta qualidade e com preços razoáveis. Entre em contato conosco o mais rápido possível se quiser saber mais. Estamos ansiosos para cooperar com você!

Uma grande parte dos nossos produtos é exportada para a Europa e as Américas, com opções padrão e personalizadas disponíveis. Podemos fabricar de acordo com seus desenhos ou amostras, usando materiais padrão ou conforme suas necessidades específicas. Escolher-nos significa escolher confiabilidade.

Materiais disponíveis

1. Aço inoxidável: SS201, SS303, SS304, SS316, SS416, SS420

2. Aço: C45 (K1045), C46 (K1046), C20

3. Latão: C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Ferro: 1213, 12L14,1215

6. Alumínio: Al6061, Al6063

7. OEM de acordo com sua solicitação

Tratamento de superfície

Recozimento, canonização natural, tratamento térmico, polimento, niquelagem, cromagem, zincagem, passivação amarela, passivação dourada, acetinado, pintura de superfície preta etc.

Método de processamento

Usinagem CNC, puncionamento, torneamento, fresamento, perfuração, retificação, brochamento, soldagem e montagem

QC e Certificado

Os técnicos fazem a autoverificação na produção e a verificação final antes da embalagem é feita pelo inspetor de qualidade profissional

ISO9001:2008, ISO14001:2001,ISO/TS 16949:2009

Pacote e prazo de entrega

Tamanho: Desenhos

Caixa/contêiner de madeira e palete, ou conforme especificações personalizadas.

Amostras de 15-25 dias. Pedido oficial de 30-45 dias

Porto: Porto de Xangai/Ningbo

Indústrias que atendemos