EPG is a professional manufacturer and exporter that is concerned with the design, development and production.

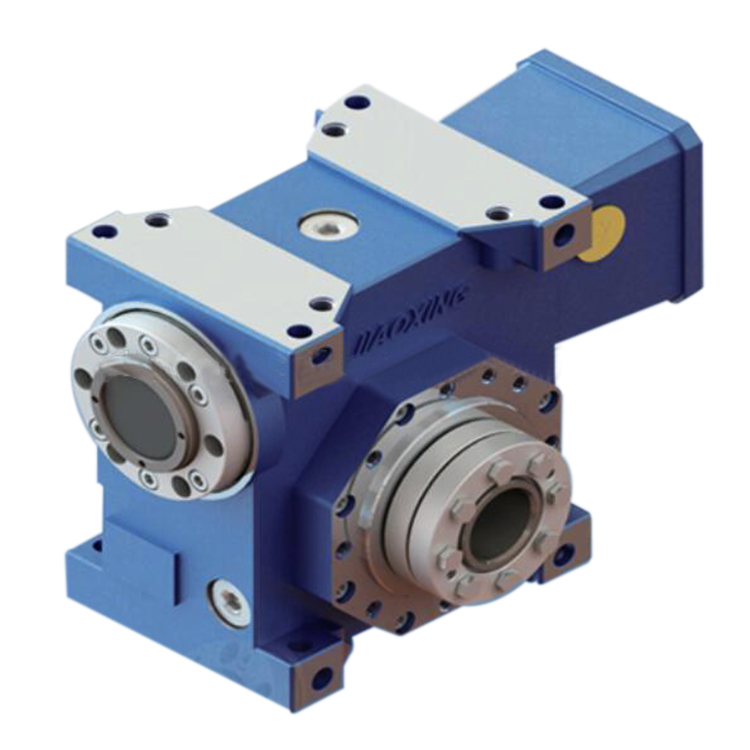

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Reduction ratio:

-

5 7.5 10 15 20 25 30 40 50 60 80 100

- Oil seals:

-

TTO,NAK

- Motor coupling:

-

Flange & shaft

- Body material:

-

Aluminium alloy & cast iron

- Available combination:

-

NMRV+NMRV,NMRV+NRV,NMRV+UDL,NMRV+PC

- Color:

-

Blue,Silver or Customised

- Warranty:

-

One year,subject to proper operation and installation

- Extra service:

-

OEM

Supply Ability

- Supply Ability:

- 8000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- 1 pc / carton,several cartons / wooden pallet

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Cases) 1 – 10 11 – 40 41 – 80 >80 Est. Time(days) 2 8 15 To be negotiated

Online Customization

Our factory has been in the manufacture & export of RV series mechanical motor reductors for years.Our quality control strictly complies with the ISO9001:2008 system,able to provide to all customers mature products in competitive prices.

Features

- Wide transmission rate, strong output torque

- Structure: base-mounted, input shaft, input flange, additional single or double output shafts

- Compact mechanical structure, light weight, small volume

- Good temperature change resistance

- Smooth operation with lower noise or vibration

- Easy mounting, free linking, high efficiency

- Wide range of application

Applications

- Widely used in material handing, automation, machine tool, aerospace, food, packing, pharamceutical, printing industry with requiremnts to lower speed driven by motors or other engines

Technical data:

| Model | RV025 030 040 050 063 075 090 110 130 150 |

| Single unit versions |

NMRV – fitted for motor flanged coupling, NRV – with input shaft, NMRV-E motor flanged coupling with worm extension shaft, NRV-E with double extension worm shaft, |

| Power | 0.06—-15KW |

| Single unit reduction ratio | 1:5 7.5 10 15 20 25 30 40 50 60 80 100 |

| Output torque | 2.6—1195N.M |

| Worm shaft | 20CrMnTi with carburizing and quenching.The hardness of surface is 56-62HRC with carbonized layer 0.5-0.8mm |

| Worm wheel | worm mandrel is HT250,and worm ring gear,Zepgn10-1 |

After-sale service:

One year warranty,subject to proper operation and installation;free technical support all the time.

Torque arm and output shaft mounted positions to request,

Quality control complying with ISO 9001:2008 and certificated,

Package for container loading,one pc / carton box,several carton boxes / wooden pallet,