Tebsa (EVER-POWER Argentina Branch)

Agricultural Gearboxes

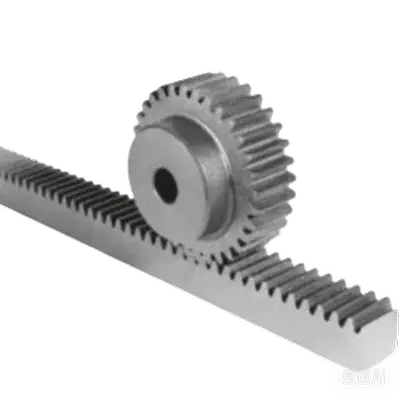

Gear & Rack

Pulley

Drive Shaft

About Us

TEBSA, HZPT’s Argentina Branch

Why Choose Teabsa

Legacy Since 1997

From day one, we’ve been shaping metal into solutions—27 years of proof that experience matters.

Half the Cost, Full Value

Save 50% compared to originals—smart savings, not shortcuts.

100% Quality Assurance

We test every gearbox ourselves, ready for Argentina’s toughest fields.

24-Hour Support

Our engineers are on it—answers in a day, every day.

Prototype to Production

Need one piece or a million? Our machines are ready to roll.

Built to Last

Our Materials and Craftsmanship

How Agricultural Gearbox Works

Picture the agricultural gearbox as the beating heart of farming machines across Argentina’s vast fields. It’s typically powered by a tractor’s PTO shaft, pulling energy straight into the gearbox to run everything from plows to seeders. But it doesn’t stop there—some setups tap hydraulic motors, belt pulleys, or chain gears to get moving, making these units real workhorses for local farmers. In Argentina, where tough terrain meets big harvests, this kind of versatility keeps the wheels turning season after season.

Dig into the mechanics, and you’ll find each gearbox has at least one input shaft and one output shaft. Set those at a 90-degree angle, and you’ve got a right-angle gearbox—known in tech terms as an orthogonal angle model. It’s a smart setup that twists power just where it’s needed, perfect for the tight corners of Argentina’s rugged farmland. These gearboxes are built to last, giving farmers here the steady, reliable torque they need to power through long days under the southern sun.

Tractors are the backbone of Argentine agriculture, churning out slow, forceful pulls to tackle jobs like tilling or hauling across the pampas. Whether it’s a manual shift, synchro-shift, or a smooth hydrostatic drive, every transmission uses shafts to send engine grunt to the differential—and the gearbox is right in the thick of it. That’s where Tebsa steps up, crafting these vital parts right here in Argentina since ’97. We’re proud to offer quality you can bank on, prices 50% below the big names, and custom solutions tailored for our local growers.

Rotary Cutter Gearbox Used in Agriculture Application

The Highest Quality

Agricultural Gearboxes for Sale

If you’re seeking customized agricultural gearboxes or products not listed on our website, don’t worry; we’re continually updating our product range. Please email us directly, and we’ll respond within 24 hours!

Agricultural ratio 1:1 rotary tiller gearbox

| Product Name | ROTARY TILLER GEARBOX |

| Material | Housing as QT450-10, Shaft as 40Cr |

| Color | Dark or Red or as customized |

| Type | Bevel gear |

| Ratio | 1:1 |

| Bearing | QC or C&U or NTN or PEER |

| Warranty | one and half year |

| Used |

Rotary tiller

|

OEM & ODM rotary lawn mower gearbox

| Product Name | Rotary lawn mower gearbox RG70 |

| Material | Housing as QT450, Shaft as 20CrMnTi |

| Color | Dark or Red or as customized |

| Type | Bevel gear |

| Ratio | 1:1.92 |

| Bearing | QC or C&U or NTN |

| Warranty | one and half year |

| Used | lawn mower |

Customized agricultural lawn mower gearbox

| Material | QT450 for housing | Ratio | 1:1.93 |

| 20CrMnTi for gear shaft | Gear model | 5 | |

| Aluminum for plate | Teeth | 12/23 | |

| Main performance parameters | Noise | 82db | 1 meter |

| Input speed | 540 rpm | / | |

| bolt torque | 23-28 NM | / |

Rotary power tiller gearbox

| Product Name | Rotary power tiller gearbox |

| Model | MCJ |

| Color | Customization |

| Material | HT250 for housing, 20CrMnTi for gear shaft. |

| Used | Rotary tiller transmission |

Tractor PTO Drive Shaft

PTO Shaft is a splined drive shaft that is generally placed on tractors or can be used to provide power backup to a separate machine. More than 8 series of PTO shafts can be offered now. These shafts are available in the following specifications:

Tractor side yoke: 6 or 21 splines push pin yoke;

Implement side yoke: 6 splines push pin shear bolt type yoke;

Tubes: Triangular tube or lemon profile tube;

Plastic guard: Yellow or black;

Rotary Tiller PTO Shaft

| Material | Stainless Steel |

| Finishing | Induction Hardened |

| Color | Black |

| Usage/Application | Tractor, Rotavator, Happy seeder, Thresher, Agriculture |

| Type | Shaft |

| Function | Power Transmission |

General Questions

When did TEBSA start its operations?

TEBSA has been in operation since 1997, establishing itself as a professional and experienced manufacturer.

How does TEBSA ensure product quality?

We offer a 100% quality guarantee for your orders, backed by ISO9001-2015 certification and rigorous inspection processes.

What production capabilities does TEBSA provide?

We have versatile mechanical capabilities, covering everything from rapid prototyping to mass production to meet your needs.

How competitive are TEBSA’s product prices?

With competitive strategic marketing, our products cost 50% less compared to original products, delivering excellent value.

How responsive is TEBSA’s team?

Our talented engineering team ensures smooth cooperation, providing feedback within 24 hours to address your inquiries.

What materials can TEBSA work with?

We handle a wide range of materials, including alloy steel, castings, die castings, aluminum, brass, zinc alloy, POM, plastic, stainless steel, iron, or as per your requirements.

What machining processes does TEBSA offer?

We provide carbonitriding, carburization, nitridation, vacuum quenching, frequency quenching, and tempering to enhance product durability.

What surface treatment options are available at TEBSA?

We offer blackening, oxidation, electrophoresis, powder coating, and phosphorization to meet various surface finishing needs.

Why choose TEBSA as a partner?

TEBSA is a reliable and trustworthy partner with extensive experience, advanced technology, and a smart team dedicated to delivering high-quality, efficient solutions for your orders.