Tebsa:your first choice

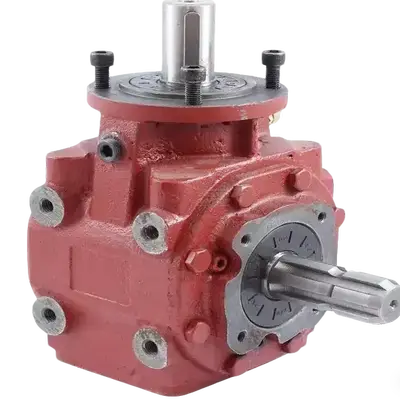

Gearbox

TEBSA: Your Expert Gearbox Manufacturer in Argentina

Since 1997, TEBSA has been a leading gearbox manufacturer in Argentina, crafting reliable solutions for farms and industries. Specializing in agricultural, bevel, helical, planetary, worm, and swing gearboxes, we power mowers, harvesters, and more with precision and strength. Our alloy steel gearboxes, forged and heat-treated, come with a 100% quality guarantee and ISO 9001-2015 certification. Offering a 50% cost advantage over original brands, we save you money without compromise. From the Pampas to Buenos Aires, TEBSA delivers durable gearboxes fast, backed by 24-hour support. Trust us for your next gearbox need.

Agricultural Gearbox

Post Hole Digger Gearbox

Rotary Mower Gearbox

Lawn Mower Gearbox

Rotary Tiller Gearbox

Fertilizer Spreader Gearbox

Agricultural Sprayer Gearbox

Rotary Cutter Gearbox

Flail Mower Gearbox

Feed Mixer Gearbox

Fertilizer Seeder Gearbox

Combine Harvester Gearbox

Potato Harvester Gearbox

Corn Headers Gearbox

Fertilizer Mixer Gearbox

Hydraulic Drive Gearbox

Hydraulic Cutters Gearbox

Worm Gearbox

EP-NRV Shaft Input Small Worm Gearbox

RV Series Worm Gearboxes

WP-Series Gearboxes

VF-Series Gearboxes

TEBSA Gearbox Applications

TEBSA, Argentina’s trusted gearbox manufacturer since 1997, builds agricultural, bevel, helical, planetary, worm, and swing gearboxes for diverse tasks. From soybean fields in the Pampas to construction sites in Buenos Aires, our gearboxes deliver power and precision. Crafted with alloy steel and backed by ISO 9001-2015 certification, they ensure durability at 50% less cost than original brands. Whether mowing pastures, driving conveyors, or rotating cranes, TEBSA’s 100% quality guarantee and 24-hour support keep your operations running smoothly. Discover how our gearboxes transform farming and industry across Argentina.

Pasture Mowing in Córdoba

In Córdoba’s rolling fields, farmers rely on TEBSA’s agricultural gearboxes to power rotary mowers. These units, built with carburized alloy steel, handle thick grass and uneven terrain with ease. A local cattle ranch uses our 100 HP gearbox to maintain pastures, cutting cleanly at 540 RPM. With a 50% cost edge, TEBSA saves them thousands compared to imported brands. Our 24-hour support ensures quick fixes, keeping downtime low during peak seasons.

Grain Conveyor Systems in Santa Fe

Santa Fe’s grain farms depend on TEBSA’s bevel and worm gearboxes for conveyor systems. These gearboxes provide precise angular power to move soybeans and wheat efficiently. A co-op in Rosario trusts our worm gearbox for its high reduction ratio, preventing jams under heavy loads. ISO-certified and 50% cheaper than competitors, our gearboxes last years in dusty conditions. TEBSA’s team responds in 24 hours, ensuring harvests stay on track.

Construction Cranes in Buenos Aires

In Buenos Aires, TEBSA’s swing gearboxes drive cranes at busy construction sites. Their compact planetary design delivers high torque for precise rotation, lifting steel beams safely. A downtown project uses our swing gearbox for its durability, forged since 1997. At half the cost of originals, it’s a budget-friendly choice with our 100% quality guarantee. TEBSA’s fast support keeps cranes moving, even on tight deadlines.

Choosing the Right Gearbox Manufacturer

To select the ideal gearbox, start by finding a trusted speed reducer gearbox manufacturer. Browse online to create a shortlist of reputable suppliers, then explore their product ranges to choose wisely. For expert insights on reducing gearboxes, check out TEBSA’s resources at agricultural-gear-boxes.com or reach out to us directly via our website.