Worm Gear And Worm Wheel

Worm Gear And Worm Wheel: A Reliable Solution for Power Transmission

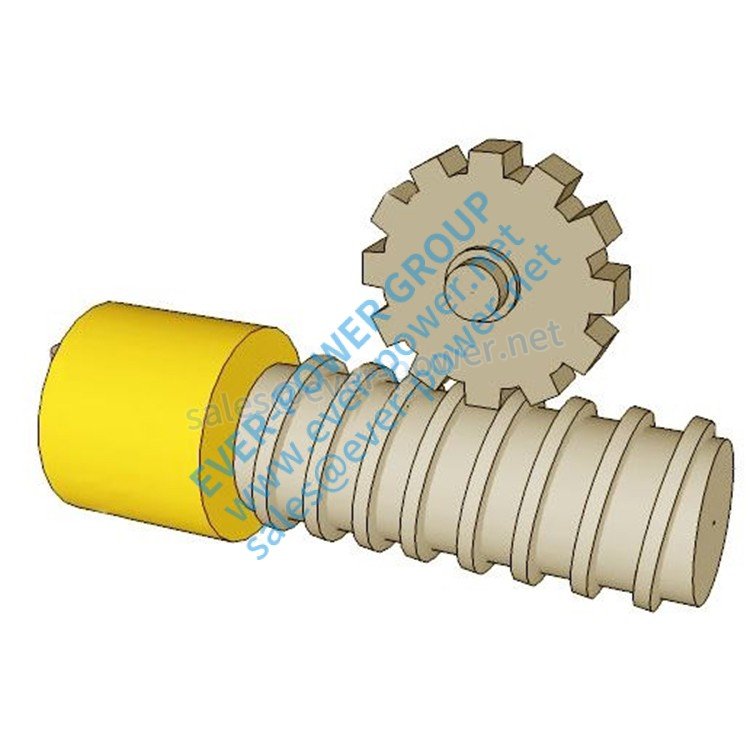

The arrangement of gears seen above is called a worm and worm wheel. This innovative design offers a reliable solution for power transmission in various industries. The worm, characterized by its brown color, features a unique structure with only one tooth, resembling a screw thread. On the other hand, the worm wheel, colored yellow, functions similarly to a traditional gear wheel or spur gear. The worm always drives the worm wheel, ensuring efficient and consistent rotation. It is important to note that the worm and worm wheel system is designed to prevent reverse rotation, as it can cause the system to lock and jam.

Applications and Common Use Scenarios

- Industrial Machinery: Worm gear and worm wheel arrangements are commonly used in industrial machinery for power transmission, ensuring smooth and precise motion in various applications.

- Automotive Sector: These gear arrangements find applications in automotive systems, such as steering mechanisms and power transmission systems, providing reliable and efficient torque conversion.

- Heavy Equipment: Worm gears and worm wheels are utilized in heavy equipment, including construction machinery and agricultural machinery, contributing to their optimal performance and durability.

A Brief History and Classification

The concept of worm gears dates back to ancient civilizations, with evidence of their use in ancient China and Greece. Over time, advancements in manufacturing technology have enhanced their design and efficiency. Worm gears can be classified based on the angle of the worm's helix, the number of starts, and the direction of rotation.

Advantages of Worm Gear and Worm Wheel

- High Gear Ratio: The worm gear and worm wheel arrangement offer a high gear ratio, allowing for a significant reduction in rotational speed while increasing torque output.

- Compact Design: The compact nature of worm gear systems makes them suitable for applications where space is limited, providing flexibility in design and installation.

- Self-Locking Feature: The inherent friction between the worm and worm wheel results in a self-locking characteristic, preventing reverse rotation and maintaining position stability.

- High Efficiency: Worm gear arrangements exhibit high efficiency due to their sliding contact, providing smooth and reliable power transmission.

Materials and Installation

Worm gears and worm wheels are commonly manufactured using materials such as steel, bronze, or brass, ensuring durability and strength. The installation process involves precise alignment of the worm and worm wheel, ensuring optimal engagement for efficient power transmission.

Maintenance, Repair, and Replacement

To maintain the performance and longevity of worm gear and worm wheel systems, regular lubrication is essential to minimize wear and friction. In case of damage or wear, professional repair or replacement by trained technicians is recommended to ensure the system's proper functioning and reliability.

Company's Other Products Business

As a leading supplier in the industry, our company specializes in providing a wide range of high-quality products, including plastic gears, agricultural gearboxes, power output shafts, sprockets, fluid couplings, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering products that meet the highest standards of quality and durability. Our competitive prices and excellent customer service have earned us a reputation for being a reliable partner in meeting various industrial needs. We welcome customers to approach us with their specific requirements for customizations based on drawings or samples.

Q&A

1. How do worm gears and worm wheels differ from traditional gear systems?

Worm gears and worm wheels differ from traditional gear systems due to their unique design with a single-tooth worm and a worm wheel. This arrangement offers a high gear ratio and self-locking feature, providing advantages in specific applications where precise power transmission is required.

2. What are the common applications of worm gears and worm wheels?

Worm gears and worm wheels find applications in various industries, including industrial machinery, automotive systems, and heavy equipment. They play a crucial role in power transmission, ensuring efficient and reliable performance in diverse scenarios.

3. How should worm gear systems be maintained?

Regular lubrication is essential for maintaining worm gear and worm wheel systems. It helps minimize wear and friction, ensuring smooth operation and prolonged lifespan. Consult the manufacturer's guidelines or seek professional advice for the appropriate lubrication schedule and techniques.

4. Can worm gears and worm wheels be repaired in case of damage?

Yes, worm gears and worm wheels can be repaired if they sustain damage. However, it is recommended to seek professional repair services provided by trained technicians who specialize in gear systems. They possess the expertise to assess the extent of damage and carry out the necessary repairs effectively.

5. Does your company offer customizations for specific gear requirements?

Absolutely! Our company takes pride in offering customizations based on customer requirements. Whether it's modifications to existing gear designs or developing entirely new solutions, we have the expertise and resources to provide tailored gear solutions that meet specific industry needs.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service