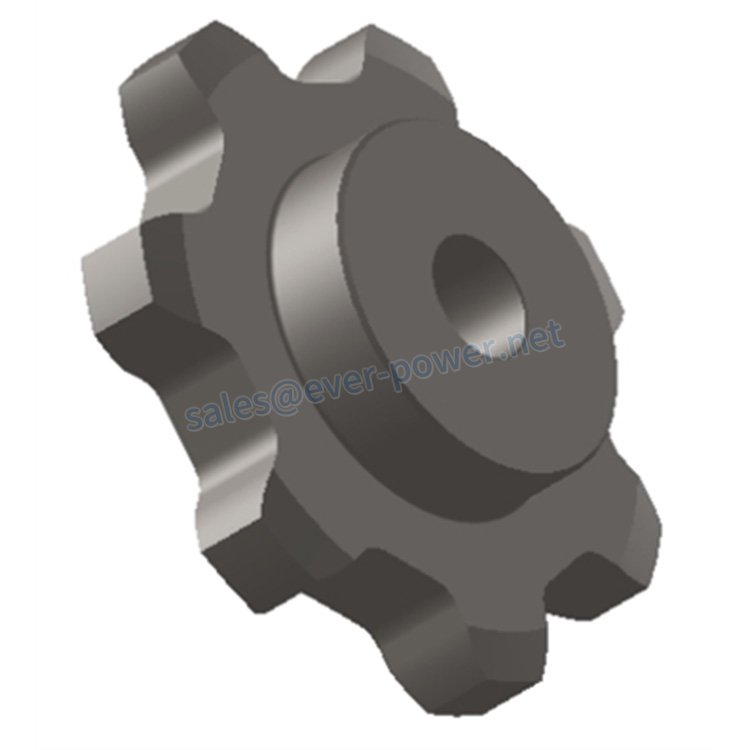

Conveyor Sprocket For S Roller Chains

Conveyor Sprocket For S Roller Chains: An Overview

Conveyor sprockets play a vital role in several industries, including agriculture, automotive, mining, and food processing. They are commonly used in conveyor systems for the movement of heavy materials and loads.

The history of sprockets dates back to the 15th century when they were used as a part of bicycles. Over the years, sprockets have evolved and have become an integral part of various machinery and equipment.

Sprockets are classified based on their design, material, and tooth profile. They are available in various materials such as stainless steel, carbon steel, and plastic. The selection of the material depends on the application and the environment in which the sprocket will be used.

Advantages of using conveyor sprockets include their ability to handle heavy loads, their durability, and their easy installation and maintenance. They are designed to provide a smooth and efficient operation of the conveyor system.

Installation and Maintenance

Installing a conveyor sprocket is a relatively simple process. The sprocket is mounted onto the shaft and secured with a set screw or keyway. Regular maintenance is essential to ensure the longevity of the sprocket. This includes regularly cleaning and lubricating the sprocket, as well as inspecting it for wear and tear.

Replacing the Conveyor Sprocket

Over time, conveyor sprockets may become worn or damaged and require replacement. When replacing a sprocket, it is essential to select a sprocket that is compatible with the conveyor system. The tooth profile and pitch of the new sprocket must match that of the old sprocket.

Other Products by Our Company

Our company specializes in providing various plastic gears used in industries, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

At our company, we prioritize the quality of our products, favorable prices, and excellent customer service. We welcome customers to come to us for drawing or sample customization.

Q&A

1. What are conveyor sprockets used for?

- Conveyor sprockets are used in conveyor systems for the movement of heavy materials and loads in various industries such as agriculture, automotive, mining, and food processing.

2. What materials are conveyor sprockets made of?

- Conveyor sprockets are available in various materials such as stainless steel, carbon steel, and plastic, depending on the application and the environment in which they will be used.

3. How are conveyor sprockets installed?

- Conveyor sprockets are mounted onto the shaft and secured with a set screw or keyway.

4. How often should conveyor sprockets be maintained?

- Regular maintenance is essential to ensure the longevity of the sprocket. This includes regularly cleaning and lubricating the sprocket, as well as inspecting it for wear and tear.

5. What other products does your company offer besides conveyor sprockets?

- Our company specializes in providing various plastic gears used in industries, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service