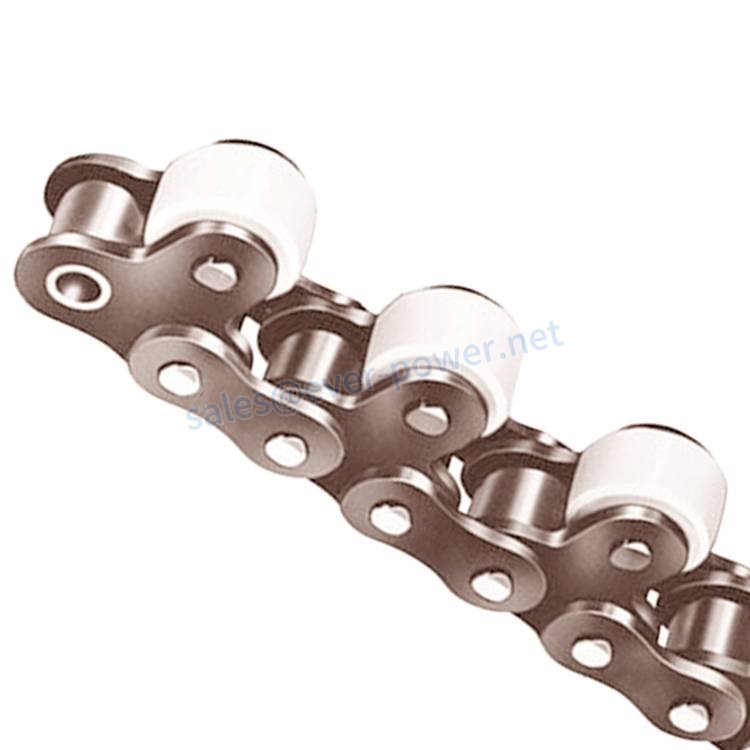

Heavy duty straight sidebar chain

Heavy Duty Straight Sidebar Chain: A Reliable Solution for Industrial Applications

When it comes to heavy-duty applications in industries, the Heavy Duty Straight Sidebar Chain is the go-to choice. This robust and durable chain is designed to withstand high loads, making it ideal for various industrial scenarios. Whether you need to transmit power, convey materials, or operate heavy machinery, this chain delivers exceptional performance and reliability.

Product History and Classification

The Heavy Duty Straight Sidebar Chain has a long history of successful usage in industries worldwide. With advancements in manufacturing techniques and materials, this chain has evolved to meet the ever-increasing demands of modern industrial applications.

This chain falls under the category of roller chains, known for their ability to transmit power efficiently. It consists of a series of interconnected rollers that engage with the teeth of sprockets, enabling smooth and precise movement.

Advantages of Heavy Duty Straight Sidebar Chain

- High Load Capacity: The Heavy Duty Straight Sidebar Chain is specifically designed to handle heavy loads, making it suitable for demanding industrial applications.

- Durability: Built with high-quality materials and precision manufacturing, this chain offers excellent durability and longevity.

- Smooth Operation: The roller design ensures smooth and reliable movement, reducing friction and enhancing efficiency.

- Wide Range of Sizes: The Heavy Duty Straight Sidebar Chain is available in various sizes and configurations, allowing for versatility in different applications.

Material and Installation

The Heavy Duty Straight Sidebar Chain is commonly made from high-quality alloy steel, which provides exceptional strength and wear resistance. The material selection ensures that the chain can withstand heavy loads and harsh operating conditions.

Installing this chain requires careful attention to detail. It is crucial to ensure proper alignment, tension, and lubrication to maximize its performance and lifespan. Following the manufacturer's installation guidelines is essential for optimal results.

Maintenance, Repair, and Replacement

To maintain the Heavy Duty Straight Sidebar Chain's performance, regular maintenance is necessary. This includes periodic lubrication, inspection for wear or damage, and timely replacement of worn-out components.

In the event of damage or failure, the chain can be repaired by replacing the damaged links or components. However, it is recommended to consult a professional or refer to the manufacturer's guidelines for complex repairs. When replacing the chain, it is important to select the appropriate size and configuration to maintain compatibility and performance.

Other Products Offered by Our Company

Aside from the Heavy Duty Straight Sidebar Chain, our company specializes in supplying a wide range of high-quality industrial products. Our product line includes:

- Plastic Gear: Ideal for various industrial applications, such as agricultural gearboxes, power output shafts, and more.

- Sprockets: Precisely designed to transmit power and ensure smooth operation in different machinery.

- Fluid Couplings: Efficiently transmit torque and dampen vibrations in power transmission systems.

- Worm Gear Reducers: Provide precise speed reduction and increased torque output in a compact design.

- Planetary Gearboxes: Offer high gear ratios and torque output for demanding applications.

We take pride in delivering high-quality products at competitive prices, backed by excellent customer service. We also offer customization services based on your specific requirements. Feel free to contact us with your drawings or samples for a tailored solution.

Frequently Asked Questions (FAQ)

1. What are the common applications of Heavy Duty Straight Sidebar Chain?

The Heavy Duty Straight Sidebar Chain finds extensive use in industries such as manufacturing, mining, agriculture, and material handling. It is commonly employed in conveyor systems, power transmission equipment, and heavy machinery.

2. Does the Heavy Duty Straight Sidebar Chain require regular lubrication?

Yes, regular lubrication is essential to ensure smooth operation and prevent premature wear. Applying a suitable lubricant at recommended intervals helps minimize friction and prolong the chain's lifespan.

3. Can the Heavy Duty Straight Sidebar Chain be repaired if damaged?

Yes, the chain can be repaired by replacing the damaged links or components. However, it is recommended to consult a professional or refer to the manufacturer's guidelines for complex repairs.

4. Are there different sizes available for the Heavy Duty Straight Sidebar Chain?

Yes, the Heavy Duty Straight Sidebar Chain is available in a wide range of sizes and configurations to suit different industrial applications. It is important to select the appropriate size based on the load and operating conditions.

5. How can I contact your company for more information or customization?

For more information about our products or to discuss customization options, please contact our sales team at [insert contact details]. We will be happy to assist you and provide the best

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service