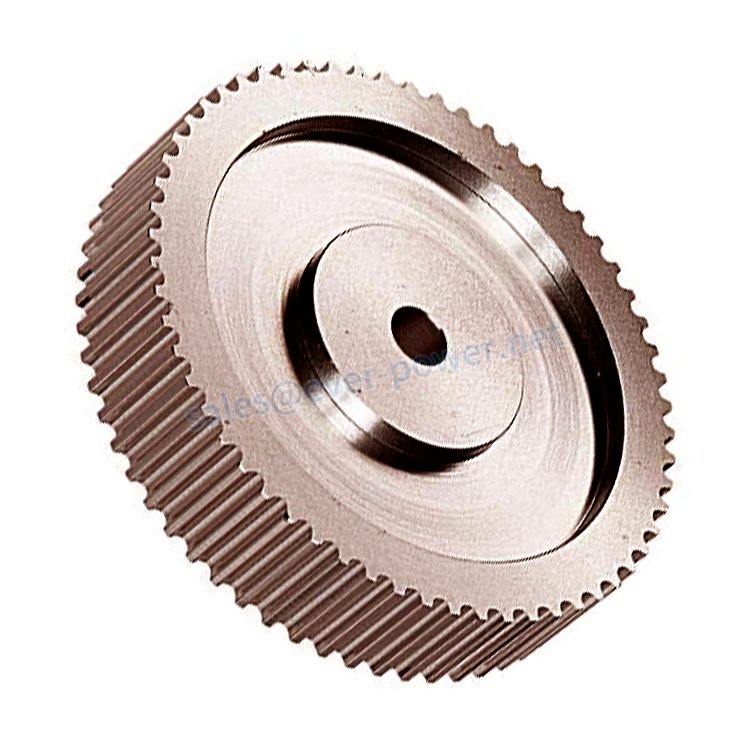

Pilot Bore Timing Pulley

Pilot Bore Timing Pulley: The Synchronous Drive Solution

Introduction

Pilot Bore Timing Pulleys play a crucial role in synchronous drives that rely on flexible components. These pulleys, along with toothed belts, efficiently overcome problems that would otherwise require the use of kinematic motion gearing or transmissions with articulated link chains. Synchronous belt drives offer excellent performance similar to chains and gearing but come with additional advantages stemming from their structural features.

Common Use Scenarios

Pilot Bore Timing Pulleys find extensive usage in various applications. Whether it's industrial machinery, automotive systems, or manufacturing processes, these pulleys ensure precise and synchronous power transmission. They are commonly employed in conveyor systems, textile machines, packaging equipment, and many other mechanical setups.

Product History and Classification

The history of timing pulleys dates back to the early 20th century when the need for synchronous power transmission systems arose. Over time, manufacturers have developed different types of timing pulleys to cater to specific requirements. These may include XL, L, H, T, and HTD profiles, among others, each designed for distinct load capacities, speed ratios, and torque transmission.

Advantages of Pilot Bore Timing Pulleys

1. Absolute Asynchronous Motion: Pilot Bore Timing Pulleys ensure transmission of absolute synchronous motion without any slipping.

2. Regular and Constant Motion: The toothed belt eliminates polygonal winding and the resultant speed variation, offering a smooth and consistent motion.

3. Non-Extendable Belt: These pulleys transmit motion without significant stretching, thereby minimizing lost motion.

4. Moderate Assembly Pre-Tension: Unlike other drive systems, Pilot Bore Timing Pulleys do not require adhesive contact between the belt and the pulley, resulting in reduced assembly pre-tension.

5. Minimal Radial Load: These pulleys exert minimal radial load on the shafts and bearings, enhancing their lifespan and reducing wear and tear.

6. High Power Transmission Capacity: Pilot Bore Timing Pulleys can transmit substantial power and handle high torques even at low speeds.

7. Silent Operation and Compact Size: Thanks to their toothed belt design, these pulleys operate silently, deliver excellent performance, occupy limited space, and require minimal maintenance.

Materials and Installation

Pilot Bore Timing Pulleys are typically constructed using durable materials such as aluminum, steel, or engineered plastics like polyamide. The choice of material depends on factors like load requirements, environmental conditions, and cost considerations.

To install these pulleys, ensure proper alignment and securely fasten them to the shaft using appropriate mounting techniques. It is essential to follow manufacturer guidelines and use the correct tools to guarantee reliable and efficient operation.

Maintenance, Repairs, and Replacement

Regular maintenance is key to extending the lifespan and performance of Pilot Bore Timing Pulleys. Periodically inspect the pulleys for signs of wear, contamination, or excessive noise. Clean them as needed and ensure proper lubrication of any bearings or moving parts.

In case of damage or failure, consult the manufacturer's guidelines to determine the appropriate repair procedure. If replacement becomes necessary, obtain a new pulley with matching specifications to ensure compatibility and optimal performance.

Our Range of High-Quality Plastic Gears and More

In addition to Pilot Bore Timing Pulleys, our company offers a wide range of high-quality plastic gears and other industrial components. Our extensive product lineup includes agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

We take pride in supplying top-notch products that meet industry standards and cater to diverse customer needs. Our commitment to providing high-quality products, competitive pricing, and excellent customer service sets us apart. We welcome customers to explore our offerings and take advantage of our customization options based on their specific drawings or samples.

Frequently Asked Questions (FAQs)

1. Q: What are the applications of Pilot Bore Timing Pulleys?

A: Pilot Bore Timing Pulleys are widely used in industrial machinery, automotive systems, and manufacturing processes. They are commonly found in conveyor systems, textile machines, packaging equipment, and more.

2. Q: How do Pilot Bore Timing Pulleys ensure precise and synchronous power transmission?

A: These pulleys, combined with toothed belts, offer absolute asynchronous motion without any slipping, resulting in precise and synchronous power transmission.

3. Q: What materials are used to manufacture Pilot Bore Timing Pulleys?

A: Pilot Bore Timing Pulleys are commonly constructed using durable materials such as aluminum, steel, or engineered plastics like polyamide, depending on the specific application requirements.

4. Q: How should Pilot Bore Timing Pulleys be installed?

A: To ensure proper installation, align the pulleys accurately and securely fasten them to the shaft using appropriate mounting techniques. Follow the manufacturer's guidelines for optimal results.

5. Q: What maintenance is required for Pilot Bore Timing Pulleys?

A: Regular maintenance is essential. Periodically inspect the pulleys for wear, contamination, or excessive noise. Clean them as needed and ensure proper lubrication of any bearings or moving parts.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service