Synchronous Drives

Synchronous Drives: Revolutionizing Power Transmission

Synchronous drives are a cutting-edge solution that has transformed power transmission in various industries. With their superior performance and efficiency, these drives have garnered immense popularity among professionals seeking optimized power delivery. Let's delve into the world of synchronous drives, exploring their history, classifications, advantages, and practical applications.

A Brief History of Synchronous Drives

The concept of synchronous drives dates back to the early 20th century when engineers envisioned a system that could provide precise power transmission with minimal energy loss. Over the years, significant advancements have been made in materials and manufacturing techniques, resulting in the creation of highly reliable synchronous drives that we rely on today.

Types of Synchronous Drives

Synchronous drives come in various forms, each designed to meet specific requirements. Some of the commonly used types include:

- Belt Drives

- Chain Drives

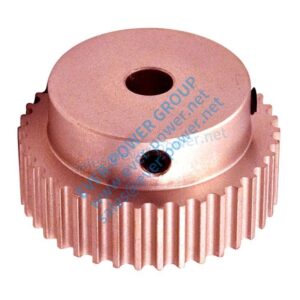

- Gear Drives

Advantages of Synchronous Drives

Synchronous drives offer a myriad of advantages that make them the preferred choice for power transmission. Here are some key benefits:

- Enhanced Power Capacity: Synchronous drives deliver an impressive 50% more horsepower capacity compared to standard high torque drives, allowing for efficient power transfer even in demanding applications.

- Compact and Lightweight: Their innovative design enables the use of smaller and lighter sprockets, reducing overall weight and enhancing system efficiency.

- Economical Solution: Synchronous drives provide a cost-effective alternative to standard high torque systems, making them an ideal choice for industries aiming to maximize performance while minimizing expenses.

- Superior Strength and Flexibility: Equipped with "EXTRA STRONG" fiberglass cords, these drives exhibit exceptional tensile strength, shock load resistance, and length stability, ensuring reliable operation even under challenging conditions.

- Outstanding Durability: The teeth and backing of synchronous drives are molded from premium quality neoprene rubber, offering excellent resistance to heat, oil, ozone, and flex fatigue. This ensures prolonged lifespan and minimized maintenance requirements.

- Friction-Resistant Wear Jacket: The self-lubricating nylon cover fabric construction protects against tooth wear and shear from friction, enabling consistent power transmission and reducing the risk of failures.

- Wide Compatibility: Many sprocket sizes are dual drilled, accommodating both inch and metric hardware, providing versatility and ease of installation.

Installation, Maintenance, and Replacement

Installing a synchronous drive system requires careful attention to detail to ensure optimal performance. Regular maintenance, including proper lubrication and periodic inspections, plays a crucial role in prolonging the drive's lifespan and preventing unexpected failures. In the event of a replacement, it is essential to follow manufacturer guidelines to guarantee compatibility and maintain system integrity.

Explore Our Range of High-Quality Industrial Solutions

Our company specializes in supplying a wide range of industrial components designed to meet the diverse needs of businesses worldwide. In addition to synchronous drives, our product portfolio includes:

- Plastic Gears

- Agricultural Gearboxes

- Power Output Shafts

- Sprockets

- Fluid Couplings

- Worm Gear Reducers

- Gears and Racks

- Detachable Chains

- Pulleys and Pulleys

- Planetary Gearboxes

- Timing Pulleys

- Bushings

We take pride in offering high-quality products at competitive prices, backed by our commitment to exceptional customer service. Whether you need standard components or require customization based on your unique specifications, we are here to assist you. Contact us today to experience our premium products and unrivaled support.

Q&A

Q1: What industries can benefit from synchronous drives?

A1: Synchronous drives find applications in a wide range of industries, including manufacturing, automotive, mining, and packaging. Their high power capacity, compact design, and cost-effectiveness make them suitable for various demanding environments.

Q2: Can synchronous drives be used in extreme temperatures?

A2: Yes, synchronous drives are engineered to withstand extreme temperatures, ensuring reliable performance in both hot and cold conditions. Their premium neoprene rubber construction provides exceptional resistance to heat, enabling seamless operation even in challenging environments.

Q3: How often should synchronous drives be maintained?

A3: Regular maintenance is crucial to ensure optimal performance and extend the lifespan of synchronous drives. It is recommended to follow the manufacturer's guidelines regarding maintenance intervals, including lubrication, inspections, and replacements as necessary.

Q4: Can I replace a standard high torque drive with a synchronous drive?

A4: Yes, synchronous drives offer a more economical solution and can be used as a direct replacement for standard high torque drives. However, it is essential to consider factors such as power requirements and system compatibility before making the switch.

Q5: Do you offer customization services for your industrial components?

A5: Absolutely! We understand that every project has unique requirements. Our team is equipped to provide customization services based on your specific needs, ensuring that our products perfectly match your application. Contact us to discuss your customization requirements.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service