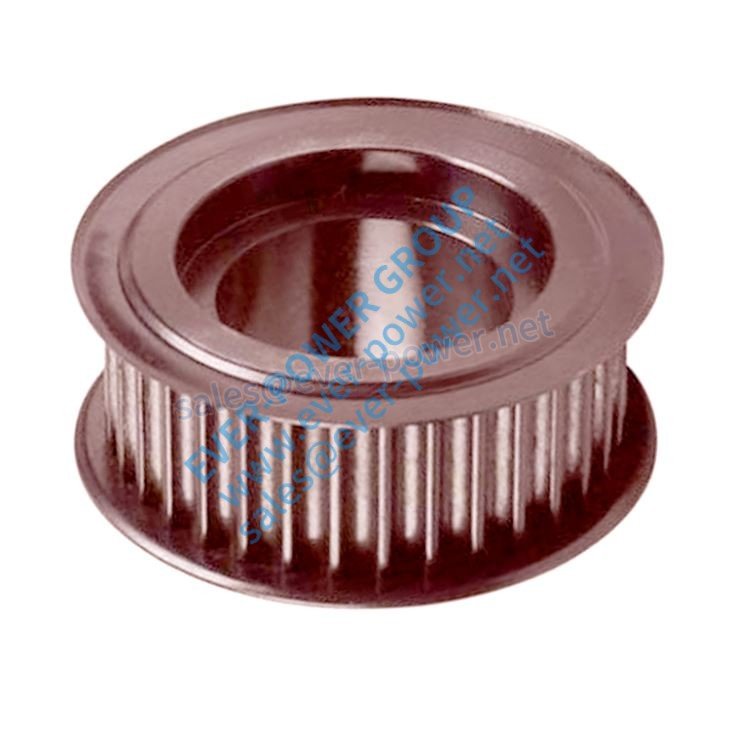

Taper Bore Timing Pulley

Taper Bore Timing Pulley: Precision Manufacturing for Accurate Belt Meshing

Taper Bore Timing Pulleys are a type of pulley that have been designed to provide accurate meshing with the belt teeth, thanks to the equally spaced grooves machined into the outside diameter. The grooves are specially designed to ensure minimum friction when the belt teeth mesh. The pulleys are manufactured with built-in minimum meshing tolerances and pitch diameters that are always larger than the outside diameter.

Applications

- Industrial machinery

- Agricultural equipment

- Textile machinery

- Printing machinery

- Medical and surgical equipment

Advantages

- Precision manufacturing guarantees accurate belt meshing

- Designed for low friction

- Built-in minimum meshing tolerances

- Non-slip synchronous power transmission

- Reduced vibration and noise

- High efficiency

- Long service life

Materials

Taper bore timing pulleys are typically made from high-grade aluminum, steel, or plastic, depending on the application requirements.

Installation, Maintenance, and Repair

Installation of taper bore timing pulleys is relatively simple and involves a few basic steps:

- Clean the shaft and bore of any debris or contaminants

- Slide the pulley onto the shaft and ensure that it is correctly aligned

- Insert the locking element and tighten the screws or bolts to the recommended torque

Maintenance involves periodic inspection of the pulley and belt to ensure that they are in good condition and functioning properly. If any damage or wear is detected, the pulley should be repaired or replaced as necessary. Repairs may involve replacing the locking element or installing a new bushing if the bore is worn or damaged.

Q&A

- What are taper bore timing pulleys used for?

- What are the advantages of using taper bore timing pulleys?

- What materials are taper bore timing pulleys made from?

- How are taper bore timing pulleys installed?

- What does maintenance of taper bore timing pulleys involve?

Taper bore timing pulleys are used to provide accurate meshing with the belt teeth in various types of industrial machinery, agricultural equipment, textile machinery, printing machinery, medical and surgical equipment, and more.

Taper bore timing pulleys offer precision manufacturing for accurate belt meshing, low friction, built-in minimum meshing tolerances, non-slip synchronous power transmission, reduced vibration and noise, high efficiency, and long service life.

Taper bore timing pulleys are typically made from high-grade aluminum, steel, or plastic, depending on the application requirements.

The installation process involves cleaning the shaft and bore, sliding the pulley onto the shaft, ensuring correct alignment, inserting the locking element, and tightening the screws or bolts to the recommended torque.

Maintenance involves periodic inspection of the pulley and belt to ensure they are in good condition and functioning properly. Repairs or replacement of the pulley or locking element may be necessary if any damage or wear is detected.

In addition to taper bore timing pulleys, our company supplies various Plastic Gear used in industry, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products at favorable prices with considerate service. We welcome customers to come to us for drawing or sample customization.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service