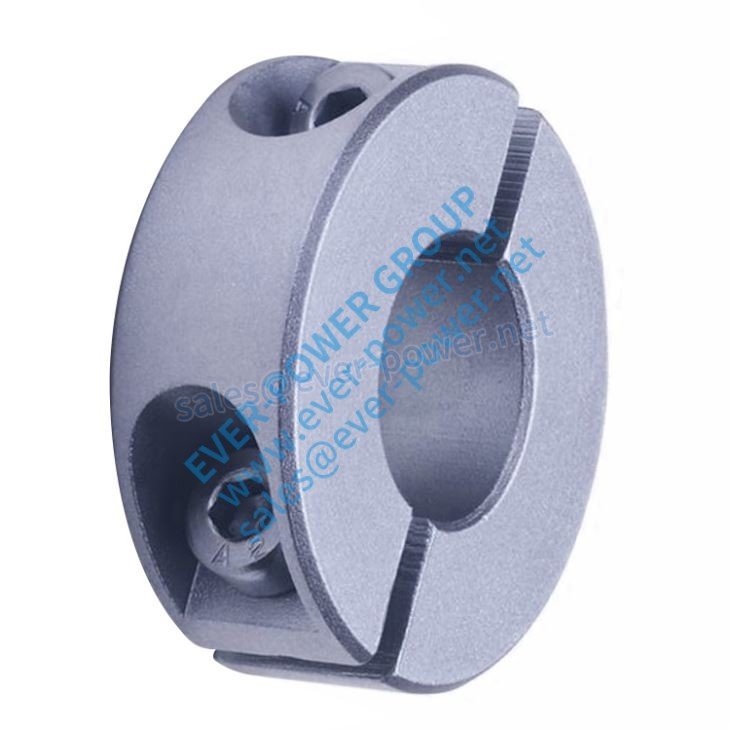

Steel Collar

Steel Collar: A High-Quality Solution for Corrosive Environments

The Climax Part 1C-056-S Clamping Collar is a reliable and durable solution made with T303 Stainless Steel, which makes it effective in corrosive environments. This steel collar is ideal for use on both hard and soft shafts, as it has a design that fully engages the shaft without marring. Additionally, it has a 360?? clamping force that ensures a secure fit and protection against shaft damage.

Advantages of Steel Collar

- Effective on hard and soft shafts

- Design fully engages the shaft without marring

- 360?? clamping force

- T303 stainless steel is effective in corrosive environments

Installation, Maintenance, and Repair

The installation of the steel collar is quick and easy. It can be secured in place using standard hex socket set screws. To ensure its longevity, regular maintenance is recommended, which includes cleaning and inspecting the collar for any signs of damage. If any damage is found, it is advisable to replace the collar immediately, as a damaged collar can cause serious damage to the shaft.

Common Use Scenarios

The steel collar is commonly used in industrial applications, including conveyor systems, power transmission equipment, and machinery. It is also used in agricultural equipment, marine equipment, and even in certain automotive applications.

Other Products by Our Company

In addition to steel collar, our company supplies a wide range of plastic gear used in industry, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products at a favorable price with considerate service. We welcome customers to come to us for drawing or sample customization.

FAQs About Steel Collar

1. What is the steel collar made of?

The steel collar is made of T303 stainless steel, which makes it effective in corrosive environments.

2. What are the advantages of using a steel collar?

A steel collar is effective on both hard and soft shafts, fully engages the shaft without marring, and has a 360?? clamping force that ensures a secure fit and protection against shaft damage.

3. How can I install the steel collar?

The steel collar can be secured in place using standard hex socket set screws.

4. How often should I perform maintenance on the steel collar?

Regular maintenance is recommended, which includes cleaning and inspecting the collar for any signs of damage.

5. Can a damaged steel collar cause damage to the shaft?

Yes, a damaged collar can cause serious damage to the shaft and should be replaced immediately if any damage is found.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service