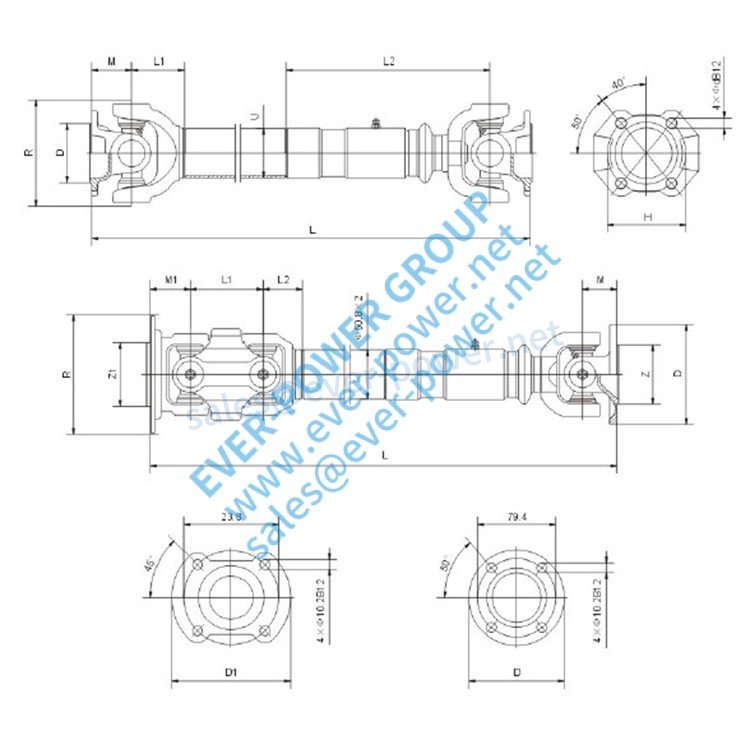

Light duty drive shaft

Light Duty Drive Shaft

A light duty drive shaft is a crucial component in a variety of mechanical systems, offering efficient power transmission and torque between rotating shafts. This versatile device is commonly used in numerous applications, including automotive, industrial machinery, and agricultural equipment. With its ability to transmit power smoothly and effectively, the light duty drive shaft has become an indispensable part of many different industries.

History and Classification

- The history of the drive shaft dates back to the early days of the Industrial Revolution when mechanical power transmission started gaining momentum.

- Drive shafts can be classified based on various factors, such as their design, material composition, and specific application requirements.

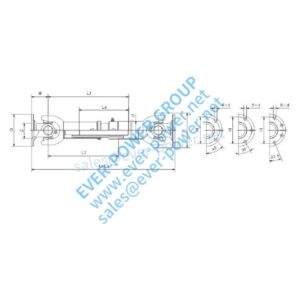

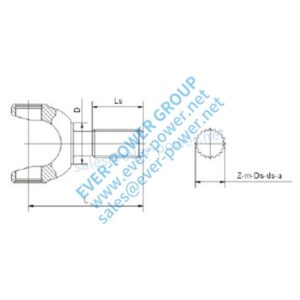

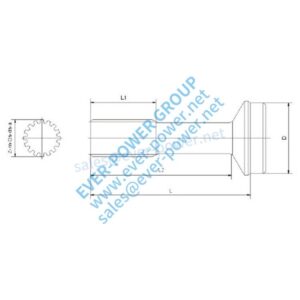

- Some common types of drive shafts include single-piece drive shafts, two-piece drive shafts, and telescopic drive shafts.

Advantages and Materials

- One of the key advantages of a light duty drive shaft is its ability to transmit power smoothly, ensuring efficient operation of the connected machinery.

- Light duty drive shafts are typically made from high-quality materials such as steel or aluminum alloys, ensuring excellent strength, durability, and resistance to wear and tear.

- These drive shafts can also be manufactured using carbon fiber, which provides a lightweight yet robust alternative.

Installation, Maintenance, and Repair

- Proper installation of a light duty drive shaft is essential for optimal performance and longevity. It requires careful alignment and secure attachment to the driven and driving components.

- Regular maintenance is crucial to ensure the drive shaft operates smoothly. This includes inspecting for any signs of damage, lubricating moving parts, and checking for proper alignment.

- In the event of damage or failure, repair or replacement of the drive shaft may be necessary. It is recommended to consult with a professional technician for proper diagnosis and repair.

- When replacing a drive shaft, it is important to select a compatible replacement part that matches the original specifications and requirements of the system.

Company's Other Products

Our company specializes in supplying a wide range of high-quality industrial components. In addition to light duty drive shafts, we offer various plastic gears used in industry, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in our commitment to producing top-notch products, offering competitive prices, and providing exceptional customer service. We welcome customers to explore our wide selection and consider customization options to meet their specific needs.

Q&A

What are the primary applications of a light duty drive shaft?

A light duty drive shaft is commonly used in automotive, industrial machinery, and agricultural equipment.

What materials are light duty drive shafts typically made from?

Light duty drive shafts are often made from steel or aluminum alloys, but carbon fiber can also be used.

What is the importance of proper installation?

Proper installation ensures optimal performance and longevity of the drive shaft.

How should a light duty drive shaft be maintained?

Regular maintenance includes inspection for damage, lubrication, and alignment checks.

What other products does the company offer?

The company offers a wide range of industrial components, including plastic gears, agricultural gearboxes, power output shafts, sprockets, and more.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service