Heavy duty drive shaft for truck

Heavy Duty Drive Shaft for Truck: A Comprehensive Guide

Heavy duty drive shafts are a crucial component of any truck's powertrain system. They are responsible for transmitting torque from the engine to the wheels, thereby propelling the vehicle forward. Heavy duty drive shafts are designed to withstand high levels of torque and stress, making them ideal for use in heavy-duty trucks, such as those used in construction, mining, and transportation industries.

History of Heavy Duty Drive Shafts

The drive shaft has been an essential part of the automobile since their inception. The first automobiles used a simple chain drive, which was gradually replaced by more efficient and reliable systems. Today, heavy duty drive shafts are made of high-strength materials, such as steel or aluminum, to withstand the high torque and stress levels generated by modern truck engines.

Classification of Heavy Duty Drive Shafts

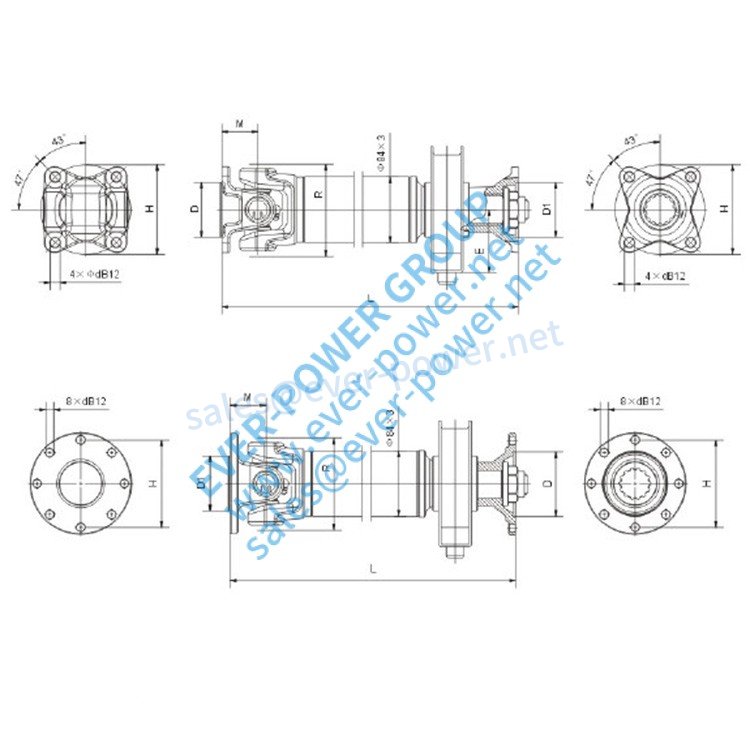

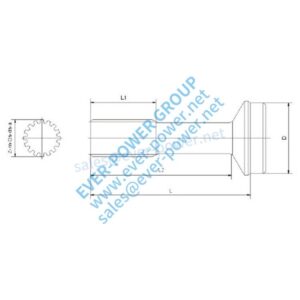

Heavy duty drive shafts can be classified according to their design and application. The most common types are single-piece drive shafts, two-piece drive shafts, and slip yoke drive shafts. Single-piece drive shafts are the simplest design and consist of a single shaft that connects the transmission to the rear axle. Two-piece drive shafts are used in trucks with longer wheelbases and consist of two sections connected by a center bearing. Slip yoke drive shafts are used in trucks with a shorter wheelbase and have a sliding yoke at one end to accommodate changes in length.

Advantages of Heavy Duty Drive Shafts

- High strength and durability

- Ability to handle high torque and stress levels

- Increased efficiency and performance of the powertrain system

- Reduces noise, vibration, and harshness

- Improved fuel efficiency and reduced emissions

Materials Used for Heavy Duty Drive Shafts

Heavy duty drive shafts are typically made of high-strength materials, such as steel or aluminum. Steel is the most common material used due to its high strength and durability. Aluminum is used in some applications where weight reduction is a priority, as it is lighter than steel but still provides the necessary strength and durability.

Installation, Maintenance, and Repair

Proper installation, maintenance, and repair of heavy duty drive shafts are critical to ensure their longevity and reliability. It is recommended to have a professional mechanic install, maintain, and repair heavy duty drive shafts to ensure proper alignment and balance. Regular maintenance, such as lubrication and inspection, can help prevent damage and prolong the life of the drive shaft. In the event of damage or failure, heavy duty drive shafts can be repaired or replaced.

Other Products Offered by Our Company

In addition to heavy duty drive shafts, our company offers a wide range of industrial plastic gears, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our products are of high quality, offered at favorable prices, and supported by considerate service. We welcome customers to come to us with drawings or samples for customization.

Q&A

1. What is a heavy duty drive shaft?

A heavy duty drive shaft is a component of a truck's powertrain system responsible for transmitting torque from the engine to the wheels, thereby propelling the vehicle forward. It is designed to withstand high levels of torque and stress, making it ideal for use in heavy-duty trucks.

2. What materials are heavy duty drive shafts made of?

Heavy duty drive shafts are typically made of high-strength materials, such as steel or aluminum. Steel is the most common material used due to its high strength and durability. Aluminum is used in some applications where weight reduction is a priority.

3. What are the advantages of heavy duty drive shafts?

Heavy duty drive shafts have several advantages, including high strength and durability, ability to handle high torque and stress levels, increased efficiency and performance of the powertrain system, reduced noise, vibration, and harshness, improved fuel efficiency, and reduced emissions.

4. How should heavy duty drive shafts be installed and maintained?

Heavy duty drive shafts should be installed, maintained, and repaired by a professional mechanic to ensure proper alignment and balance. Regular maintenance, such as lubrication and inspection, can help prevent damage and prolong the life of the drive shaft.

5. What other products does your company offer?

In addition to heavy duty drive shafts, our company offers a wide range of industrial plastic gears, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service