Fluid couplings

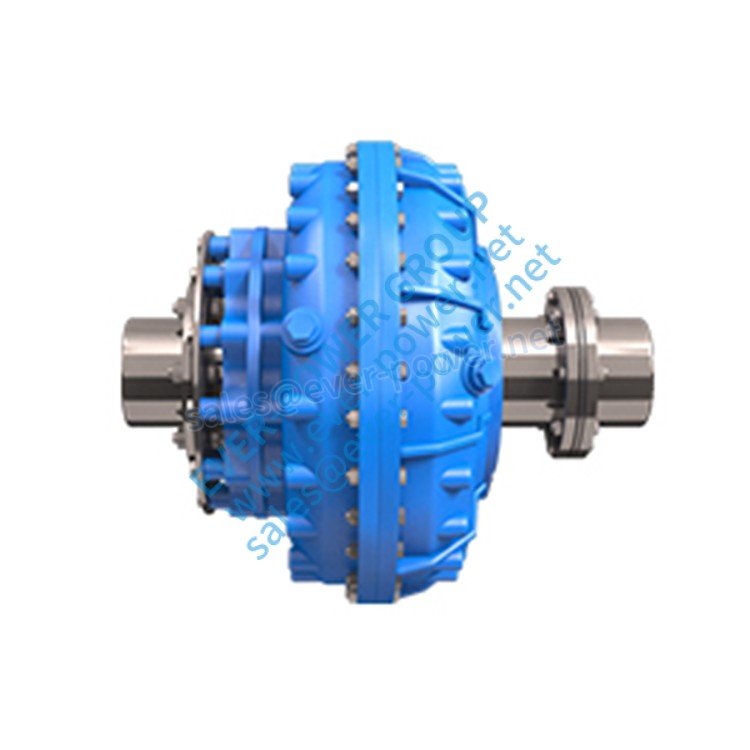

Introduction to Fluid Couplings

A fluid coupling is a device that improves the starting capability of an electric motor, protects the motor against overloading, dampens shocks, handles load fluctuations and torsional vibrations, and balances and distributes loads in case of multimotor drives. It is widely used in various industries and applications.

Features of Fluid Couplings

- Improves the starting capability of electric motor

- Protects motor against overloading

- Dampens shock, load fluctuation, and torsional vibration

- Allows balance and load distribution in multimotor drives

Applications of Fluid Couplings

- Belt conveyors

- Scraper conveyors

- All kinds of conveyors

- Bucket elevators

- Ball mills

- Hoisters

- Crushers

- Excavators

- Mixers

- Straighteners

- Cranes

- And many more

Fluid couplings are essential in these applications for their ability to ensure smooth and efficient operation.

Selection of Fluid Couplings

When selecting a fluid coupling, it is important to consider the technical data sheet and power chart provided. These resources help determine the proper size of the fluid coupling based on the power transmitted and the speed of the motor. Additionally, the dimensions of the shaft ends of the motor and driven machine (or reducer) must be specified, including diameter, tolerance or fit, length, width, and depth of the keys. For special requirements, such as fluid couplings with belt pulleys or brake pulleys, detailed technical data should be provided.

YOXz is a type of fluid coupling with a moving wheel that is connected to an elastic axle connecting machine. It offers three connection types and is known for its tight structure and small axle size. YOXz fittings have a wide usage and simple structure, making them easy to use in various applications. The connection style of YOXz allows for easy installation without the need to move the electromotive machine and decelerating machine. The size of YOXz is determined by the customer's specifications.

YOXp is another type of fluid coupling, designed as a connection style with a belt tray and hydraulic coincidence machine. It is suitable for equipment transported by belt. The connection size of the electromotive machine axle and the detailed specification and size of the belt tray should be provided by the customer.

YOXf is a type of fluid coupling that is connected on both sides. It has a longer axle size but a simple structure, making it easy to fix and amend without moving the electromotive machine and decelerating machine. The relevant elastic axle connecting machine, connecting size, and outer size are similar to YOXe type.

Proper installation, maintenance, and repair procedures should be followed when dealing with fluid couplings. It is also important to understand how to replace the fluid coupling if necessary.

Other Products

Our company specializes in supplying various industry-related products, including plastic gears, agricultural gearboxes, power output shafts, sprockets, worm gear reducers, gears and racks, detachable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, and bushings. We are committed to providing high-quality products at favorable prices and offering considerate customer service. We welcome customers to come to us with their drawing or sample customization needs.

Q&A

1. What are the main features of fluid couplings?

2. In which applications are fluid couplings commonly used?

3. How do I select the right size of fluid coupling?

4. What is the advantage of using YOXz fluid couplings?

5. What other products does your company supply?

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service