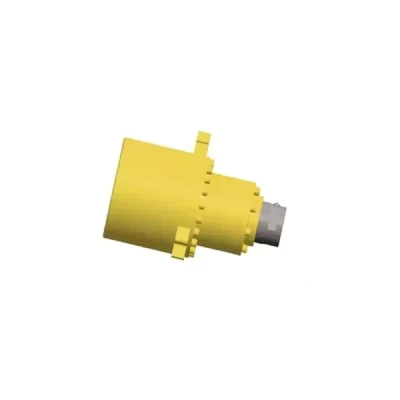

Good Quality Hydraulic Tightening Cylinder for Large Excavator Price

All content on this page comes from the internet and is only used as a reference for product selection. Our products are replacement parts and are not original spare parts. Our replacement parts can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory or supplier to purchase.

Good Quality Hydraulic Tightening Cylinder for Large Excavator Price

A hydraulic tightening cylinder is a specialized hydraulic device used to control and precisely apply tension to bolts, studs, or other fasteners. It is primarily used in applications where accurate and uniform tightening of fasteners is critical, such as in assembly lines, construction, or maintenance of machinery and structures.

Usage Scenarios of Hydraulic Tightening Cylinder

Hydraulic tightening cylinders are extensively used in various industries and scenarios where accurate and controlled tensioning of fasteners is crucial. Here are some common applications:

- Assembly of Machinery and Equipment: Hydraulic tightening cylinders are used to assemble machines and equipment in manufacturing production lines, engines, turbines, pumps, compressors, etc. They ensure proper and uniform tightening of bolts and studs, maintaining the integrity and reliability of the assembled components.

- Construction and Structural Engineering: Hydraulic tightening cylinders are employed for tensioning bolts and anchor rods in structural steel connections, bridges, towers, and other large-scale structures. They help achieve the required clamping force, ensuring the stability and safety of the erected structures.

- Automotive Industry: Hydraulic tightening cylinders are used in engine assembly, transmission assembly, chassis construction, and other critical applications in the automotive sector. They ensure precise and consistent tightening of bolts in engine components, cylinder heads, crankshafts, and other critical areas, ensuring optimal performance and preventing leaks.

- Wind Energy: Hydraulic tightening cylinders play a vital role in the assembly and maintenance of wind turbines. They are used to tension bolts, rotor blades, and nacelle components in the tower sections. Proper tensioning is essential to withstand the high loads and dynamic forces experienced by wind turbines.

- Petrochemical and Oil Refineries: Hydraulic tightening cylinders are used for flange connections in pipelines, vessels, and reactors. They ensure leak-free and secure joints in critical process equipment, where the integrity of the relationships is paramount for safety and operational efficiency.

- Maintenance and Repair: Hydraulic tightening cylinders are used in equipment overhauls, machinery repairs, and reassembly after maintenance procedures to ensure proper torque and pressure of fasteners.

- Subsea and Offshore Applications: Hydraulic tightening cylinders are utilized in subsea and offshore environments, such as oil rigs and underwater structures. They help maintain the integrity of bolted connections subjected to harsh conditions, underwater pressures, and vibration.

- Railway and Transportation: Hydraulic tightening cylinders are employed to assemble and maintain railway tracks, bridges, and infrastructure. They ensure proper tensioning of bolts and fasteners in rail joints, ensuring the stability and safety of railway infrastructure.

Advantages of Hydraulic Tightening Cylinder

- Precision: Hydraulic tightening cylinders provide precise control over the force applied to the fasteners, ensuring consistent and accurate tensioning across multiple fasteners.

- Adjustable Tension: Hydraulic tightening cylinders can precisely adjust the applied tension.

- Efficiency: Hydraulic tightening cylinders offer faster and more efficient tightening than manual methods.

- Safety Features: Hydraulic tightening cylinders often include safety features to prevent over-tensioning or damage to fasteners.

- Compact and Portable: Hydraulic tightening cylinders are typically compact and portable, allowing them to be used in various locations and applications.

- Customizable Designs: Hydraulic tightening cylinders can be customized to suit specific applications.

Materials and Installation of Hydraulic Tightening Cylinder

Hydraulic tightening cylinders are available in various sizes, load capacities, and configurations to accommodate different fastener sizes and geometries. They can be made of materials such as aluminum, stainless steel, and carbon steel.

Installation of hydraulic tightening cylinder involves connecting the cylinder to a hydraulic pump and power supply. It is important to follow the manufacturer's guidelines for specific installation requirements and procedures.

Maintenance and Repair of Hydraulic Tightening Cylinder

Proper maintenance of hydraulic tightening cylinders is essential to ensure their optimal performance, longevity, and reliability.

- Regular Inspection: Conduct regular visual inspections of the hydraulic tightening cylinder to check for any signs of leaks, damage, or wear.

- Lubrication: Follow the manufacturer's recommendations for lubrication intervals and lubricant types.

- Cleaning: Keep the hydraulic tightening cylinder clean and free from dirt, debris, and contaminants.

- Seal Inspection and Replacement: Inspect the seals regularly for wear, damage, or degradation.

- Pressure Calibration and Testing: Periodically check and calibrate the pressure gauge or transducer to ensure accurate tension measurements.

- Hydraulic Fluid Maintenance: Monitor the hydraulic fluid level and quality regularly.

Other Products of Our Company

Our company mainly supplies various plastic gears for industrial use, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc.

We offer high-quality products, preferential prices, and thoughtful services. Customers are welcomed to customize with drawings and samples.

Frequently Asked Questions

1. What is a hydraulic tightening cylinder used for?

A hydraulic tightening cylinder is used to control and precisely apply tension to bolts, studs, or other fasteners in applications where accurate and uniform tightening of fasteners is critical.

2. What are the advantages of hydraulic tightening cylinder?

Hydraulic tightening cylinders provide precise control, adjustable tension, efficiency, safety features, compact and portable designs, and customizable configurations.

3. What materials can be used for hydraulic tightening cylinder?

Hydraulic tightening cylinders can be made of materials such as aluminum, stainless steel, and carbon steel.

4. What are the maintenance practices for hydraulic tightening cylinder?

Maintenance practices for hydraulic tightening cylinder include regular inspection, lubrication, cleaning, seal inspection and replacement, pressure calibration and testing, and hydraulic fluid maintenance.

5. What are the other products of your company?

Our company mainly supplies various plastic gears for industrial use, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service