Agricultural Roller Chain Sprockets

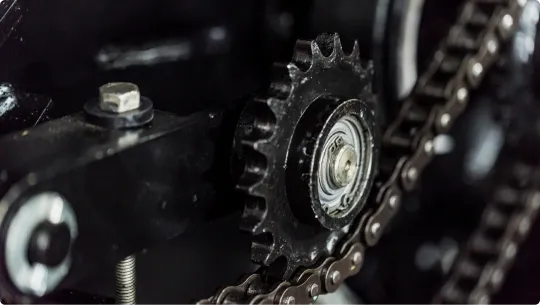

Introduction to Agricultural Roller Chain Sprockets

Roller chain sprockets are essential components in agricultural machinery, enabling efficient power transmission and smooth operation. These sprockets, made from high-quality heat-treated carbon steel, are designed to withstand wear, abrasion, and heavy shock loads, ensuring long-lasting performance.

Common Usage Scenarios

Agricultural roller chain sprockets find wide applications in various agricultural operations. Here are some common scenarios where these sprockets are extensively used:

- Harvesting machines: Agricultural roller chain sprockets play a crucial role in the smooth functioning of crop harvesters, ensuring efficient gathering and processing of crops.

- Tillage equipment: These sprockets are essential in tillage machinery, facilitating tasks such as plowing, tilling, and cultivation, enabling farmers to prepare the soil for planting.

- Feed processing: In the feed industry, roller chain sprockets are utilized in machinery for crushing, grinding, and mixing animal feed, ensuring the production of high-quality feed products.

- Seeders and planters: Sprockets are integral components in seeders and planters, enabling precise and uniform seeding, improving crop establishment and yield.

- Hay and forage equipment: Agricultural sprockets contribute to the efficient operation of hay balers, forage harvesters, and other equipment used for baling and processing hay.

History and Classification

Roller chain sprockets have a long history and have evolved significantly over time. They are classified based on various factors, including:

- Number of teeth: Sprockets can have different tooth counts, allowing for the customization of power transmission ratios and speed.

- Pitch diameter: This measurement determines the overall size of the sprocket and affects the speed and torque characteristics of the machinery.

- Hub configuration: Sprockets come with different hub styles, such as plain, split, and detachable hubs, providing versatility for installation and maintenance.

Advantages and Materials

Agricultural roller chain sprockets offer several advantages, making them the preferred choice for farmers and agricultural machinery manufacturers:

- High durability: These sprockets are hardened and made from heat-treated carbon steel, ensuring excellent wear resistance and long service life.

- Corrosion resistance: Alloy and stainless steel sprockets are available, making them suitable for food-grade applications and providing extra protection against corrosion.

- Smooth power transmission: The precise design of roller chain sprockets ensures efficient power transfer, reducing energy loss and maximizing productivity.

- Easy installation and maintenance: With various hub configurations and easy-to-follow installation procedures, these sprockets simplify maintenance tasks and minimize downtime.

Installation, Maintenance, and Repair

Proper installation, maintenance, and timely repair are vital for optimizing the performance and longevity of agricultural roller chain sprockets. Here are some guidelines:

- Installation: Follow the manufacturer's instructions for correct alignment, secure mounting, and appropriate lubrication to ensure smooth operation.

- Maintenance: Regularly inspect the sprockets for wear, lubricate as recommended, and promptly address any issues or abnormalities to prevent further damage.

- Repair: If a sprocket shows signs of damage or wear beyond repair, it is crucial to replace it with a compatible and high-quality replacement to maintain optimal performance.

Other Products Offered by Our Company

Our company specializes in supplying a wide range of industrial plastic gears and related accessories. In addition to agricultural roller chain sprockets, we offer the following products:

- Agricultural gearboxes

- Power output shafts

- Hydraulic couplings

- Worm gear reducers

- Gear racks

- Removable chains

- Pulleys and pulleys

- Planetary gearboxes

- Timing pulleys

- Bushings

With our commitment to high-quality products, competitive pricing, and exceptional customer service, we welcome customization requests and assure you of a satisfying experience.

Questions and Answers

Q1: What are the key advantages of agricultural roller chain sprockets?

A1: Agricultural roller chain sprockets offer high durability, corrosion resistance, smooth power transmission, and easy installation and maintenance.

Q2: What are the common usage scenarios for these sprockets?

A2: These sprockets are extensively used in harvesting machines, tillage equipment, feed processing machinery, seeders and planters, and hay and forage equipment.

Q3: How should roller chain sprockets be maintained?

A3: Regular inspection, proper lubrication, and prompt addressing of any issues or abnormalities are essential for maintaining roller chain sprockets.

Q4: Can agricultural roller chain sprockets be repaired?

A4: In case of severe damage or wear, replacement with a compatible and high-quality sprocket is recommended for optimal performance.

Q5: What other products does your company offer?

A5: Our company also supplies agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, and bushings.

Author: lmc

Disclaimer: All content on this page is sourced from the Internet and is intended only as a reference for product selection. Our products are aftermarket accessories and are not original spare parts. We do not hold the original trademarks mentioned in the content. Our accessories are designed to perfectly fit the original spare parts. If you require original spare parts, please contact the respective manufacturers.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service