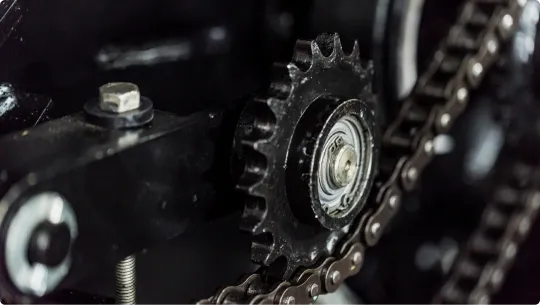

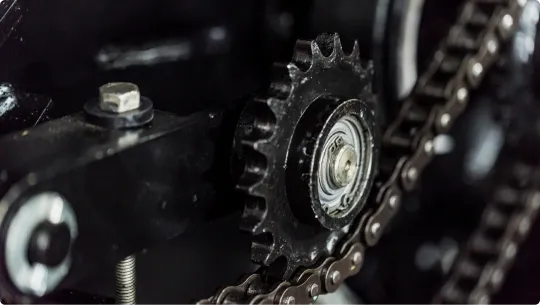

QD Sprocket No.41 Single Type

QD Sprocket No.41 Single Type: A Comprehensive Guide

QD Sprocket No.41 Single Type is an essential component in power transmission systems, providing means to transmit rotational motion between shafts. This comprehensive guide will delve into the details of the product, including its history, classification, advantages, available product materials, usage scenarios, installation process, maintenance and repair, and replacement.

The History of QD Sprocket No.41 Single Type

QD Sprocket No.41 Single Type has been used for several years in power transmission systems. Its popularity stems from its ease of installation and removal, thanks to the utilization of QD bushings.

Classification of QD Sprocket No.41 Single Type

QD sprockets are classified based on the number of teeth, pitch, and bore size. QD Sprocket No.41 Single Type has a single type and is compatible with chain number 41 and a bore size of 1 inch.

Advantages of QD Sprocket No.41 Single Type

- Easy installation and removal process due to the utilization of QD bushings

- High load capacity, able to withstand heavy loads and transmit power effectively

- Standardized design, following industry standards for easy interchangeability

- Compact design, allowing for efficient use of space

- Low maintenance cost, requiring minimal maintenance and reducing overall costs

Available Product Materials

QD Sprocket No.41 Single Type is available in various materials such as steel, stainless steel, and plastic. The choice of material depends on the application, environmental conditions, and cost considerations.

Usage Scenarios for QD Sprocket No.41 Single Type

QD Sprocket No.41 Single Type is widely used in different power transmission applications, such as agricultural machinery, conveyor systems, and industrial equipment. It is used in applications that require the transfer of rotational motion between two or more shafts.

Installation Process of QD Sprocket No.41 Single Type

The installation process of QD Sprocket No.41 Single Type involves the following steps:

- Prepare tools and materials required for installation.

- Clean the shaft and sprocket surface to ensure proper contact.

- Position the sprocket and align it with the shaft.

- Install the QD bushing onto the shaft, ensuring a secure fit.

- Secure the sprocket to the QD bushing using appropriate fasteners.

- Perform a thorough inspection to ensure proper installation.

Maintenance and Repair of QD Sprocket No.41 Single Type

QD Sprocket No.41 Single Type requires regular inspection for wear and proper lubrication to ensure smooth operation. It is essential to follow the manufacturer's maintenance recommendations for optimal performance and longevity. In case of damage or wear, the sprocket can be repaired by replacing the worn-out parts or the entire sprocket.

Replacement of QD Sprocket No.41 Single Type

When replacing QD Sprocket No.41 Single Type, it is crucial to choose the correct size, pitch, and bore size. The replacement process involves removing the old sprocket and QD bushing and installing a new sprocket and QD bushing using the installation process outlined above.

Other Products from Our Company

We mainly supply various industrial plastic gears, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, etc. We offer high-quality products, preferential prices, and thoughtful services. Welcome customers to customize with pictures and samples.

FAQ (Frequently Asked Questions)

- Q: How do I choose the correct QD sprocket size for my application?

- Q: Can I reuse a QD bushing after removal?

- Q: What maintenance is required for QD sprockets?

- Q: Can QD sprockets be used in high-speed applications?

- Q: Are QD sprockets compatible with different chain sizes?

A: The selection of the QD sprocket size depends on factors such as the desired speed ratio, torque requirements, and chain pitch. Consulting the manufacturer's guidelines or seeking assistance from a technical expert can help determine the appropriate size.

A: It is generally not recommended to reuse a QD bushing after removal, as the bushing may experience wear or damage during installation or removal. It is safer and more efficient to use a new QD bushing for each installation.

A: QD sprockets typically require regular inspection for wear and proper lubrication to ensure smooth operation. It is important to follow the manufacturer's maintenance recommendations for optimal performance and longevity.

A: Yes, QD sprockets can be used in high-speed applications. However, it is essential to consider factors such as balancing, alignment, and lubrication to ensure safe and reliable operation at high speeds.

A: QD sprockets are available in various sizes to accommodate different chain sizes. It is crucial to ensure that the chain pitch matches the sprocket teeth to ensure proper engagement and reliable power transmission.

Author: lmc

Disclaimer: The content of this page comes from the internet, and it is only used as a reference for product selection. Our products are aftermarket accessories and not original spare parts. We are not the holder of the original trademark of the content. Our accessories can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory to purchase.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service