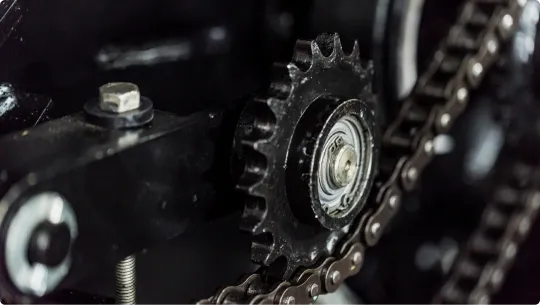

QD Sprocket No.40 Single Type

Applications and Introduction to QD Sprocket No.40 Single Type

QD Sprocket No.40 Single Type is a type of sprocket commonly used in power transmission systems. It is a key component in transferring power between rotating shafts. This sprocket uses a QD bushing system to mount onto a shaft. The QD bushing is a split taper bushing that allows for easy installation and removal of the sprocket. QD Sprocket No.40 Single Type is widely used in various industries such as mining, agriculture, and construction. It is commonly found in conveyors, elevators, and drive systems.

History and Classification of QD Sprocket No.40 Single Type

The QD Sprocket No.40 Single Type has a long history in the power transmission industry. It is classified as a type of roller chain sprocket, which is widely used in various conveying systems. The sprocket is available in various sizes and materials, making it suitable for a wide range of applications.

Advantages of QD Sprocket No.40 Single Type

- Easy Installation and Removal: QD bushings can be easily mounted onto a shaft without the need for special tools or equipment. They can be removed quickly, reducing downtime and maintenance costs.

- High Load Capacity: QD bushings are designed to withstand high torque and radial loads, making them suitable for heavy-duty applications.

- Standardized Design: QD bushings are designed to conform to industry standards for easy interchangeability.

- Compact Design: QD bushings take up less space than traditional mounting methods, allowing for more compact designs and efficient use of space.

- Low Maintenance Cost: QD bushings require little maintenance and can be easily replaced when necessary, reducing maintenance costs and downtime.

Product Materials and Manufacturing Process of QD Sprocket No.40 Single Type

QD Sprocket No.40 Single Type is typically made of high-quality steel or other durable materials. The manufacturing process involves several steps, including:

- Material Preparation: Acquire raw materials, such as steel, according to specifications.

- Cutting to Size: Cut the raw materials to the appropriate size for the sprocket.

- Forging or Casting: Forge or cast the sprocket into the desired shape.

- Machining: Machine the sprocket to create the teeth and other features.

- Rolling: Roll the teeth to ensure proper tooth profile and load-carrying capacity.

- Heat Treatment: Heat-treat the sprocket to improve its strength and durability.

- Surface Treatment: Apply a surface treatment, such as painting or plating, to protect against corrosion and wear.

- Quality Inspection: Perform a quality inspection to ensure that the sprocket meets industry standards and specifications.

Installation, Maintenance, and Repair of QD Sprocket No.40 Single Type

The installation, maintenance, and repair of QD Sprocket No.40 Single Type is a simple process that can be accomplished using the following steps:

- Prepare Tools and Materials: Gather all necessary tools and materials for the installation, maintenance, or repair process.

- Clean Shaft and Sprocket Surface: Use a cleaning agent to remove any dirt or debris from the mounting surfaces of the shaft and sprocket.

- Position Sprocket: Position the sprocket onto the shaft in the desired location.

- Install QD Bushing: Slide the QD bushing onto the shaft and tighten the screws until the bushing is fully seated onto the shaft.

- Secure Sprocket: Slide the sprocket over the QD bushing and tighten the set screws to secure the sprocket onto the bushing.

- Check: Double-check the installation to ensure that the sprocket is securely mounted and properly aligned.

- Maintenance: QD Sprocket No.40 Single Type requires little maintenance other than periodic inspection for wear and damage. If the sprocket or bushing is damaged or worn out, it can be easily replaced.

- Repair: If the sprocket or bushing is damaged, it can be repaired by replacing the damaged parts with new ones.

FAQs

1. What is the maximum torque capacity of QD Sprocket No.40 Single Type?

The maximum torque capacity of QD Sprocket No.40 Single Type is dependent on the size and material of the sprocket. Please consult the manufacturer's specifications for more information.

2. Are QD bushings interchangeable between different sprocket sizes?

No, QD bushings are designed to be used with specific sprocket sizes. Please consult the manufacturer's specifications for more information.

3. Can QD bushings be reused?

Yes, QD bushings can be reused if they are still in good condition and have not reached the end of their service life. Please consult the manufacturer's specifications for more information.

4. What is the advantage of using QD bushings over other mounting methods?

The advantage of using QD bushings is their ease of installation and removal, which reduces downtime and maintenance costs.

5. What is the typical service life of QD Sprocket No.40 Single Type?

The service life of QD Sprocket No.40 Single Type is dependent on a variety of factors, such as the operating conditions and maintenance practices. Please consult the manufacturer's specifications for more information.

Author: lmc

We also offer a wide range of industrial plastic gears, such as agricultural gearboxes, power output shafts, hydraulic couplings, worm gear reducers, gear racks, removable chains, pulleys and pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our high-quality products are competitively priced and backed by excellent customer service. We welcome customers to contact us for customized products based on pictures and samples.

Disclaimer: All the content on this page comes from the internet and is only used as a reference for product selection. Our products are accessories rather than original spare parts; we are not the holder of the original trademark of the content. Our products are only suitable for aftermarket accessories rather than original spare parts. Our accessories can perfectly fit the original spare parts; if you need to purchase original spare parts, please contact the original factory to purchase.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service