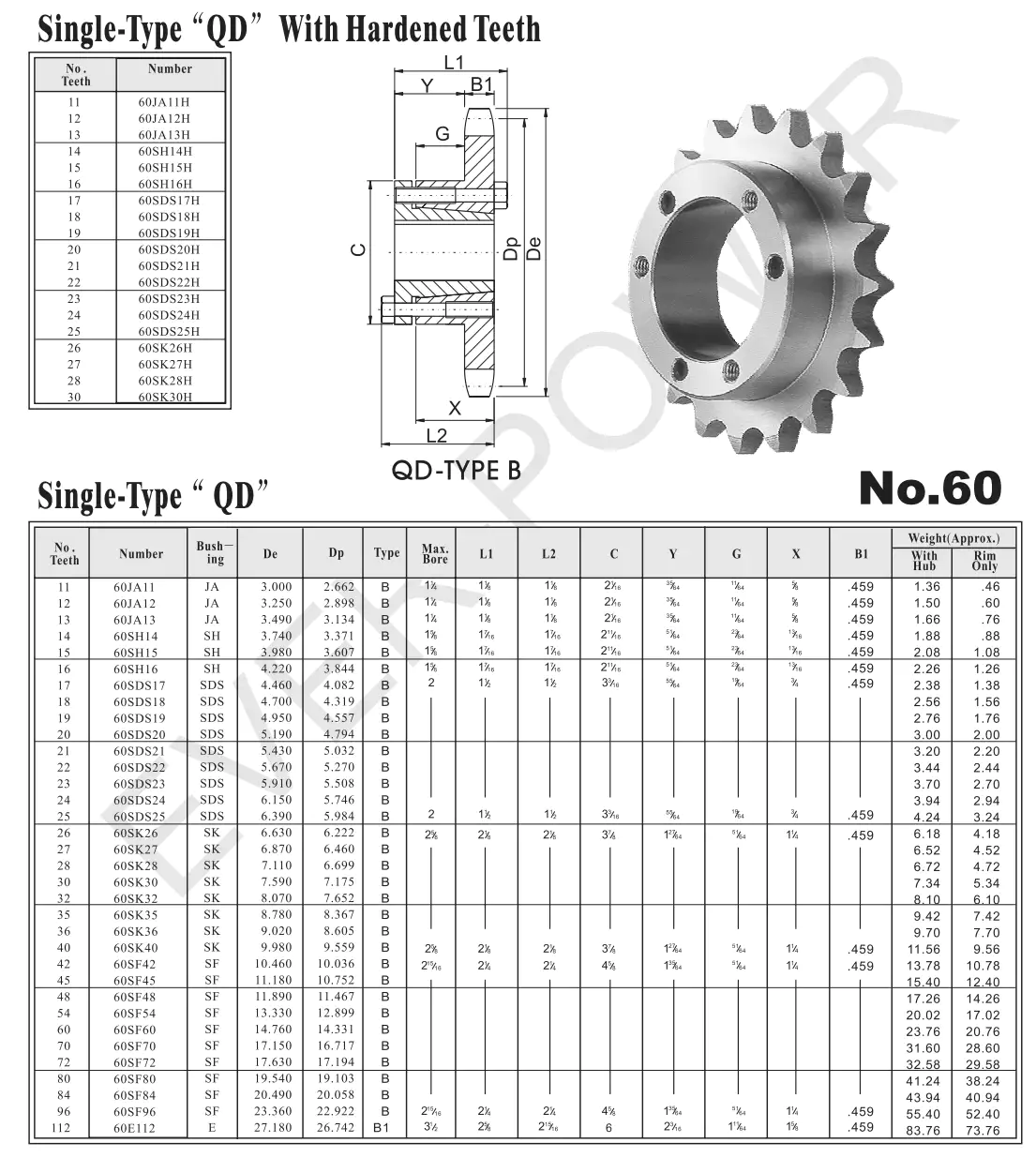

QD Sprocket No.60 Single Type

Introduction to QD Sprocket No.60 Single Type

QD Sprocket No.60 Single Type is a type of sprocket that belongs to the QD sprocket series. QD sprockets are widely used in various transmission systems. They are key components in power transmission systems, providing a reliable and efficient means of transferring torque and rotation between shafts.

Usage Scenarios of QD Sprocket No.60 Single Type

QD Sprocket No.60 Single Type is commonly used in a wide range of applications. Here are a few examples of its usage scenarios:

- 1. Industrial Machinery: QD Sprocket No.60 Single Type is often found in industrial machinery, such as conveyor systems and manufacturing equipment. Its durable construction and reliable power transmission make it ideal for these demanding environments.

- 2. Agricultural Equipment: QD Sprocket No.60 Single Type is also utilized in agricultural machinery, such as tractors and harvesters. Its ability to handle high loads and provide efficient torque transfer ensures smooth operation in agricultural applications.

- 3. Material Handling Systems: QD Sprocket No.60 Single Type is commonly used in material handling systems, including forklifts and automated conveyor belts. Its easy installation and low maintenance requirements make it a preferred choice for these applications.

These are just a few examples of the many applications where QD Sprocket No.60 Single Type can be found. Its versatility and reliability make it a popular choice in various industries.

Product History and Classification

QD Sprocket No.60 Single Type has a rich history dating back many years. It has evolved and improved over time to meet the changing needs of industries. Today, it is classified as a high-quality sprocket known for its durability and performance. With its standardized design, it can be easily interchanged with other sprocket types, providing flexibility in various applications.

Advantages of QD Sprocket No.60 Single Type

- 1. Easy Installation: QD Sprocket No.60 Single Type features a user-friendly design that allows for quick and hassle-free installation.

- 2. High Load Capacity: This sprocket can withstand high loads, ensuring reliable power transmission even in demanding conditions.

- 3. Versatility: QD Sprocket No.60 Single Type is compatible with various types of chains, providing flexibility in different applications.

- 4. Compact Design: With its compact design, this sprocket minimizes the space required for installation.

- 5. Low Maintenance: QD Sprocket No.60 Single Type requires minimal maintenance, reducing overall maintenance costs and downtime.

Available Product Materials

QD Sprocket No.60 Single Type is typically manufactured using high-quality steel, ensuring strength and durability. However, it is also available in other materials such as stainless steel or plastic, depending on specific application requirements.

Installation, Maintenance, and Repair

Installation Process:

- Prepare Tools and Materials: Gather the necessary tools and materials required for the installation process, such as wrenches and lubricants.

- Clean Shaft and Sprocket Surface: Ensure the shaft and sprocket surfaces are clean and free from any dirt or debris that may affect the installation.

- Position the Sprocket: Align the sprocket with the shaft, ensuring proper alignment of the keyway and key on the shaft.

- Install QD Bushing (if applicable): Slide the QD bushing onto the shaft, aligning it with the sprocket and keyway.

- Secure the Sprocket: Tighten the locking screws of the QD bushing to securely attach the sprocket to the shaft.

Maintenance:

To maintain optimal performance of QD Sprocket No.60 Single Type, regular inspections and lubrication are recommended. Inspect the sprocket and QD bushing for any signs of wear or damage, and replace them if necessary. Apply a suitable lubricant to ensure smooth operation and reduce friction.

Repair and Replacement:

In case of damage or wear, it is advisable to replace the entire QD Sprocket No.60 Single Type assembly, including the sprocket and QD bushing, to ensure proper functioning and compatibility. Follow the installation process to replace the sprocket and QD bushing.

Manufacturing Process of QD Sprocket

- Raw Material Preparation: Select high-quality steel or other suitable materials as the raw material for manufacturing the sprocket.

- Cutting: Cut the raw material into the desired shape and size to form the sprocket blank.

- Forging or Casting: Heat the sprocket blank and shape it through forging or casting to achieve the required strength and structure.

- Machining: Precisely machine the sprocket to create the teeth and other necessary features.

- Teeth Rolling: Roll the teeth to ensure accurate tooth profiles and enhance the sprocket's performance.

- Heat Treatment: Heat treat the sprocket to improve its hardness, strength, and wear resistance.

- Surface Treatment: Apply surface treatment, such as coating or plating, to enhance the sprocket's corrosion resistance and appearance.

- Quality Inspection: Perform rigorous quality inspections to ensure the sprocket meets the required standards and specifications.

Frequently Asked Questions (FAQ)

- Q: What are the advantages of using QD Sprocket No.60 Single Type?

- Q: How do I install a QD sprocket?

- Q: What is the manufacturing process of QD sprockets?

- Q: How can I ensure the proper alignment of the sprocket and QD bushing during installation?

- Q: Are QD sprockets compatible with other types of chains?

A: QD Sprocket No.60 Single Type offers easy installation, high load capacity, versatility, compact design, and low maintenance requirements.

A: To install a QD sprocket, gather the necessary tools and materials, clean the shaft and sprocket surface, align and position the sprocket, secure it using a QD bushing if applicable, and perform a final inspection.

A: The manufacturing process includes raw material preparation, cutting, forging or casting, machining, teeth rolling, heat treatment, surface treatment, and quality inspection.

A: Proper cleaning of the shaft and sprocket surface, as well as careful positioning and alignment of the keyway and key, are essential steps to achieve proper alignment.

A: Yes, QD sprockets are designed to be compatible with various types of chains, ensuring versatility and flexibility in different applications.

Author: lmc

All the content on this page comes from the Internet and is only provided as a reference for product selection. Our products are accessories and not original spare parts. We are not the holder of the original trademark. Our accessories can perfectly fit the original spare parts. If you need to purchase original spare parts, please contact the original factory.

We also offer a wide range of other industrial plastic gears and accessories to meet your needs:

- Agricultural Gearboxes

- Power Output Shafts

- Hydraulic Couplings

- Worm Gear Reducers

- Gear Racks

- Removable Chains

- Pulleys and Pulleys

- Planetary Gearboxes

- Timing Pulleys

- Bushings

For more information, please refer to the following image:

Questions and Answers

- Q: What are the main applications of QD Sprocket No.60 Single Type?

- Q: Can QD Sprocket No.60 Single Type be customized?

- Q: What materials are available for QD Sprocket No.60 Single Type?

- Q: How often does QD Sprocket No.60 Single Type require maintenance?

- Q: Can QD Sprocket No.60 Single Type be replaced without replacing the entire assembly?

A: QD Sprocket No.60 Single Type is commonly used in industrial machinery, agricultural equipment, and material handling systems.

A: Yes, QD Sprocket No.60 Single Type can be customized according to specific requirements.

A: QD Sprocket No.60 Single Type is primarily made of high-quality steel, but it can also be manufactured using stainless steel or plastic.

A: QD Sprocket No.60 Single Type requires minimal maintenance, reducing overall maintenance costs and downtime.

A: It is recommended to replace the entire QD Sprocket No.60 Single Type assembly, including the sprocket and QD

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service