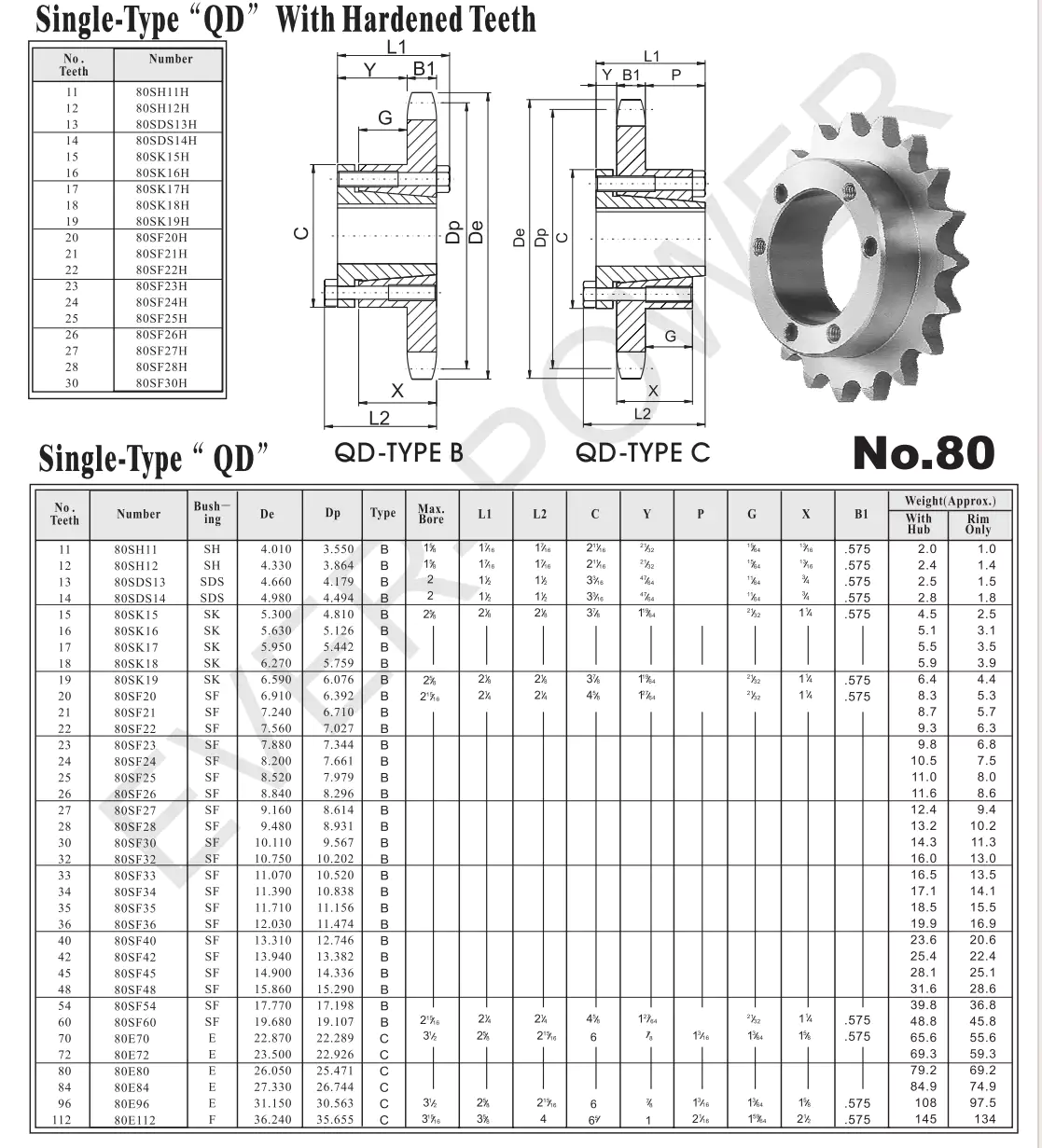

QD Sprocket No.80 Single Type

QD Sprocket No.80 Single Type

The QD Sprocket No.80 Single Type is a high-quality sprocket designed for power transmission systems. It is specifically engineered to work seamlessly with QD bushings, providing easy installation and removal of the sprocket. The sprocket is built to offer reliable performance and durability in various applications.

Introduction to QD Sprocket No.80 Single Type

The QD Sprocket No.80 Single Type is a crucial component used in power transmission systems. It is known for its compatibility with QD bushings, which simplifies the installation and removal process. The sprocket ensures efficient power transfer while maintaining a secure connection.

Common Usage Scenarios

The QD Sprocket No.80 Single Type finds extensive application in various industries, including:

- Material handling equipment

- Agricultural machinery

- Conveyor systems

- Industrial machinery

With its reliable performance and versatility, this sprocket is an excellent choice for demanding power transmission applications. It can handle heavy loads and withstand harsh operating conditions.

Product History and Classification

The QD Sprocket No.80 Single Type has a rich history in the field of power transmission. It has been refined and developed over time to meet evolving industrial needs. This sprocket falls under the category of roller chain sprockets, which are widely used in power transmission systems.

Advantages of QD Sprocket No.80 Single Type

- Easy installation and removal process

- High load capacity for heavy-duty applications

- Standardized design ensures compatibility with various sprockets and bushings

- Compact design suitable for limited space installations

- Low maintenance requirements, reducing overall costs

Available Product Materials

The QD Sprocket No.80 Single Type is manufactured using high-quality materials, ensuring durability and reliable performance. Common materials include:

- Steel: Provides excellent strength and resistance to wear

- Stainless steel: Offers corrosion resistance for challenging environments

- Aluminum: Provides a lightweight option for specific applications

Installation, Maintenance, and Repair

Proper installation, maintenance, and repair are crucial for optimum performance and longevity of the QD Sprocket No.80 Single Type. Follow these guidelines:

Installation:

- Gather all necessary tools and materials

- Thoroughly clean the shaft and sprocket surface

- Align the sprocket correctly with other components in the power transmission system

- Utilize appropriate tools and techniques to install the QD bushing onto the shaft

- Tighten the set screw to securely fasten the sprocket

- Double-check the installation to ensure proper alignment and functionality

Maintenance and Repair:

To maintain and repair the QD Sprocket No.80 Single Type:

- Regularly inspect the sprocket for signs of wear, damage, or misalignment

- Keep the sprocket clean and free from debris or contaminants

- Replace any worn or damaged components promptly

- Follow proper lubrication and tensioning procedures

Replacement:

If the QD Sprocket No.80 Single Type needs to be replaced:

- Follow the removal process to safely remove the existing sprocket

- Inspect the shaft and other components for any damage or wear

- Install the new sprocket following the proper installation process

- Ensure proper alignment and secure fastening

- Perform necessary checks and tests to verify functionality

Manufacturing Process of QD Sprocket

The QD Sprocket No.80 Single Type undergoes a meticulous manufacturing process to ensure top-quality and reliable performance:

- Raw material preparation: Carefully selected materials are prepared for production

- Cutting to size: Specialized cutting equipment shapes the raw materials to the required dimensions

- Forging or casting: The sprocket is forged or cast to achieve the desired shape and structure

- Machining: Precision machining is performed to ensure accurate sizing and shape

- Rolling: The teeth of the sprocket are rolled to achieve the correct shape and size

- Heat treatment: The sprocket undergoes heat treatment to enhance its strength and durability

- Surface treatment: A surface coating is applied to protect the sprocket from corrosion and damage

- Quality inspection: Each sprocket is thoroughly inspected to ensure it meets the highest quality standards

This thorough manufacturing process guarantees that the QD Sprocket No.80 Single Type delivers exceptional performance and reliability in demanding power transmission applications.

FAQ

- What are QD sprockets mainly used for?

QD sprockets are primarily used in power transmission systems to transfer power between components efficiently and reliably. - What are QD bushings and their purpose?

QD bushings are specialized components designed to mount sprockets onto shafts. They facilitate easy installation and removal of sprockets as needed. - What advantages do QD bushings offer?

QD bushings provide various advantages, including easy installation and removal, high load capacity, standardized design for compatibility, compact design for space efficiency, and low maintenance requirements. - How can a QD bushing be properly installed?

To install a QD bushing correctly, follow these steps: gather tools and materials, clean the shaft and sprocket surface, position the sprocket, install the QD bushing using appropriate techniques, secure the sprocket with the set screw, and perform a thorough check of the installation. - What is the manufacturing process of QD sprockets?

The manufacturing process of QD sprockets involves preparing raw materials, cutting them to size, forging or casting, machining to precise dimensions, rolling the teeth, heat treatment for strength, surface treatment for protection, and quality inspection to ensure top-notch quality.

Author: lmc

Disclaimer: All the content on this page is sourced from the internet and is provided solely as a reference for product selection. Our products are aftermarket accessories and not original spare parts. We are not the holder of the original trademark mentioned in the content. Our accessories perfectly fit the original spare parts. For original spare parts, please contact the respective manufacturer.

Explore Our Other Product Businesses

We are a leading supplier of various industrial plastic gears, catering to diverse needs in different industries. Our product range includes:

- Agricultural gearboxes

- Power output shafts

- Hydraulic couplings

- Worm gear reducers

- Gear racks

- Removable chains

- Pulleys and pulleys

- Planetary gearboxes

- Timing pulleys

- Bushings

We pride ourselves on offering high-quality products, competitive prices, and exceptional customer service. We welcome customization based on pictures and samples.

About us

We guarantee top-quality products at the best prices in China! Special orders are welcome, and if you’re interested in any of our products, feel free to reach out for more detailed information. We ensure our products are safe, high-quality, and reasonably priced. Please contact us as soon as possible if you’d like to learn more. We’re eager to cooperate with you!

A large portion of our products is exported to Europe and the Americas, with both standard and custom options available. We can manufacture according to your drawings or samples, using standard materials or as per your specific requirements. Choosing us means choosing reliability.

Materials Available

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Surface Treatment

Annealing, natural canonization, heat treatment, polishing, nickel plating, chrome plating, zinc plating,yellow passivization, gold passivization, satin, Black surface painted etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC & Certificate

Technicians self-check in production,final-check before package by professional Quality inspector

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

Package & Lead Time

Size: Drawings

Wooden Case/Container and pallet, or as per customized specifications.

15-25days samples. 30-45days offcial order

Port: Shanghai/Ningbo port

Industries We Service